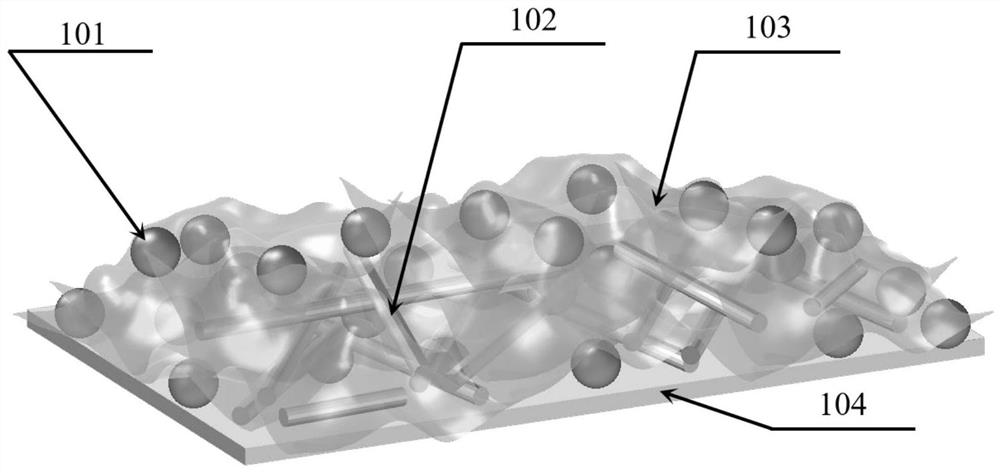

Ion and electron composite conduction electrode and in-situ preparation method thereof

An electronic composite, in-situ preparation technology, applied in battery electrodes, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc. It can meet the problems of large-scale preparation, and achieve the effect of simple method, cancellation of post-processing steps, and improved dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, add 3kg of brass powder and 10kg of zirconia grinding balls into the agate ball mill jar. Next, continue to add 1 kg of nano-hydroxyapatite suspension with a solid content of 50%. Place the ball mill jar with the powder on a planetary ball mill for ball milling and dispersion for 1 hour. During this process, the metal zinc component in the brass powder and water slowly undergo a hydrogen evolution reaction, and the Zn is slowly released from the surface. 2+ . Produced Zn 2+ instead of Ca 2+ , and in-situ cation exchange with hydroxyapatite near the surface of metal zinc to generate zinc-hydroxyapatite, a compound with cation conductivity. Compared with adding zinc-hydroxyapatite powder directly, the zinc-hydroxyapatite generated in this way can not only achieve more uniform dispersion, but also avoid the step of ion exchange by soaking in zinc-containing solution , saving process and cost.

[0032] After the ball mill tank was cooled, 1.25 kg of polyethylen...

Embodiment 2

[0035] First, add 3.5kg of zinc powder and 10kg of zirconia grinding balls into the agate ball mill jar. Then, continue to add 1.5 kg of sodium dihydrogen phosphate solution with a solid content of 30%. Put the ball mill jar with the powder on a swing ball mill for ball milling and disperse for 1 hour. During this process, zinc powder and water slowly undergo hydrogen evolution reaction, and Zn is slowly released from the surface. 2+ , and release OH in situ - . Produced Zn 2+ in OH - With the aid of, instead of Na + , with H 2 PO 4 - Combine on the surface of metal zinc to generate Zn in situ 3 (PO 4 ) 2 This ionically conductive compound. Zn produced in this way 3 (PO 4 ) 2 , compared to the direct addition of Zn 3 (PO 4 ) 2 Powder can achieve uniform dispersion on the molecular scale.

[0036] After the ball mill tank was cooled, 1 kg of sodium polyacrylate (15% solid content) and polyvinylpyrrolidone (15% solid content) solutions were added respectively,...

Embodiment 3

[0039] First, add 4kg of lead powder and 10kg of zirconia grinding balls to the agate ball mill jar. Next, continue to add the mixed solution of disodium hydrogen phosphate (solid content is 5%) and bismuth ammonium citrate (solid content is 5%) of 2kg. Place the ball mill jar with the powder on a horizontal ball mill for ball milling and disperse for 1 hour. During this process, lead powder and water slowly undergo hydrogen evolution reaction, and Pb is slowly released from the surface. 2+ , and release OH in situ - . Produced Pb 2+ in OH - With the aid of, instead of Na + , with HPO 4 2- Combine on the surface of metallic lead to generate Pb in situ 3 (PO 4 ) 2 This ionically conductive compound. At the same time, lead can undergo a spontaneous in-situ electrodisplacement reaction with bismuth ammonium citrate, forming Bi metal particles on the surface of lead, and supplementing Pb 2+ The concentration of ions is conducive to the continued occurrence of ion excha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com