Novel production process of thionocarbamate

A production process and thiourethane technology are applied in the new production process field of thiourethane, can solve the problems of incomplete reaction, environmental protection hazards, easy to use substandard, etc., and achieve less by-products, high safety, and sufficient reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

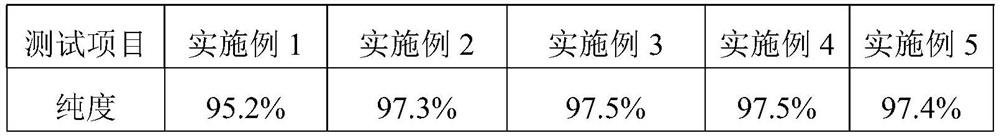

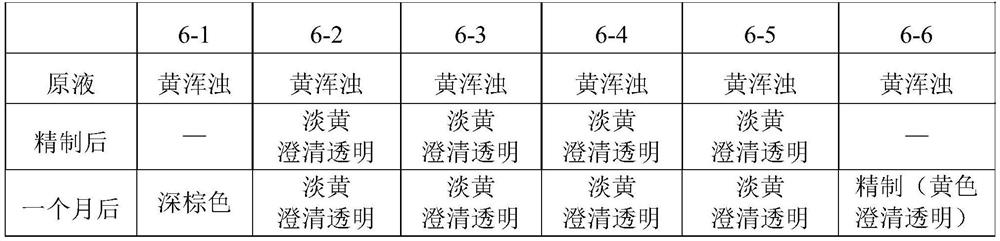

Examples

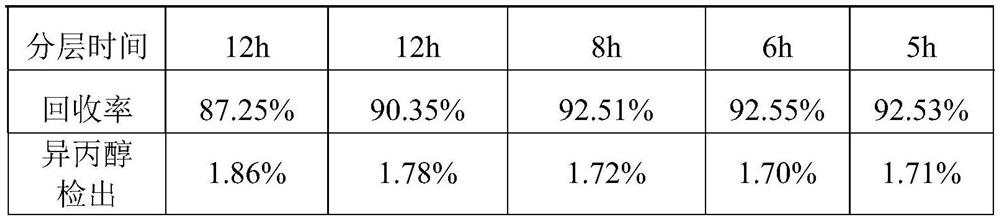

Embodiment 1

[0026] A kind of production technology of thiourethane, comprises the steps:

[0027] 1. Weigh 137g of water in a flask, dissolve 49.7g of chloroacetic acid solid in the water, start stirring, weigh 31.6g of soda ash, add soda ash to the flask, there will be a lot of CO when adding soda ash 2 Gas was generated; after adding soda ash, the reaction was stirred for 10 minutes to obtain a colorless transparent solution, pH=7.09.

[0028] 2. Add 97.1 g of xanthate several times in small amounts to the solution, the solution gradually becomes light yellow, and the temperature is 30-50°C.

[0029] 3. After stirring for 2 hours, add 35.3 g of monoethylamine to the solution at a temperature of 30-50°C, and stir for 3 hours after adding ethylamine.

[0030] 4. Let it stand for 12 hours to separate the liquid. Dark red tail liquid and light yellow turbid IPET are obtained, and a layer of gray-green mud-like intermediate layer will be formed between the tail liquid and thiourethane, whi...

Embodiment 2

[0033] A novel production process of thiourethane, comprising the steps of:

[0034] (1) Add 167ml of water to a 1L four-necked bottle, start stirring, and add 100g of 70% chloroacetic acid and 92.3g of 32% liquid caustic soda to the four-necked bottle at the same time at a controlled rate. After the reaction, a colorless and transparent solution is obtained, pH=7.23, continue Stir for 10 minutes;

[0035] (2) Add 138.5 g of xanthate to the solution of (1) several times in small amounts, control the reaction temperature to ≤45°C, and stir for 2.5 hours after adding the materials;

[0036] (3) Slowly add 52.3 g of ethylamine to the solution of (2), control the reaction temperature ≤ 45 ° C, stir for 3 hours after adding the material, and obtain an aqueous solution of thiourethane and sodium thioglycolate;

[0037] (4) The reacted material is settled in a separatory funnel, after 12 hours of natural settlement, the upper layer is taken to obtain a yellow turbid thiourethane sto...

Embodiment 3

[0040] A novel production process of thiourethane, comprising the steps of:

[0041] (1) Add 165ml of water to a 1L four-necked bottle, start stirring, and add 100g of 70% chloroacetic acid and 92.3g of 32% liquid caustic soda to the four-necked bottle at the same time under control, and obtain a colorless and transparent solution after the reaction, pH=7.25, continue Stir for 10 minutes;

[0042] (2) Add 138.5 g of xanthate several times in small amounts to the solution of (1), control the reaction temperature to ≤45° C., and stir for 2.5 hours after adding the materials; the solution after complete reaction is filtered through filter paper;

[0043](3) Slowly add 52.3 g of ethylamine to the solution of (2), control the reaction temperature ≤ 45 ° C, stir for 3 hours after adding the material, and obtain an aqueous solution of thiourethane and sodium thioglycolate;

[0044] (4) The reacted material is settled in a separatory funnel, after 8 hours of natural settlement, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com