Rod-like triethylene diamine and preparation method thereof

A technology for triethylenediamine and triethylenediamine crude product, which is applied in the field of rod-shaped triethylenediamine and its preparation, can solve the problems of affecting product quality and production efficiency, unfavorable material flow, low crystallinity and the like, and achieves hard agglomeration , Conducive to storage, low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation process of the present invention is carried out in a recrystallizer, and the crystallizer is a kind of in MSMPR crystallizer, DTB crystallizer or Oslo crystallizer, preferably MSMPR crystallizer.

[0031] The purity of the triethylenediamine prepared by the present invention is greater than 99.99%. If one wants to obtain a higher-purity triethylenediamine product, the method described in the present invention can also be used to carry out multiple recrystallizations.

Embodiment 1

[0035] Add 1115g of triethylenediamine crude product and 545g of absolute ethanol to the MSMPR crystallizer, under the action of stirring, dissolve completely at 55°C, then add 10g of gas-phase method hydrophobic silica, and then control its fluid linear velocity to 15cm / s, Gradually lower the temperature to 15°C at a cooling rate of 0.01°C / min to 0.2°C / min, and keep the temperature constant for 30 minutes, in which the temperature is lowered at 0.01°C / min in the cooling range of 38°C to 32°C, and finally the crystalline slurry is suction-filtered, and the obtained solid is wet Dry the material at 40°C and 35KPa for 6 hours, and sieve it with a standard sieve to obtain the triethylenediamine product.

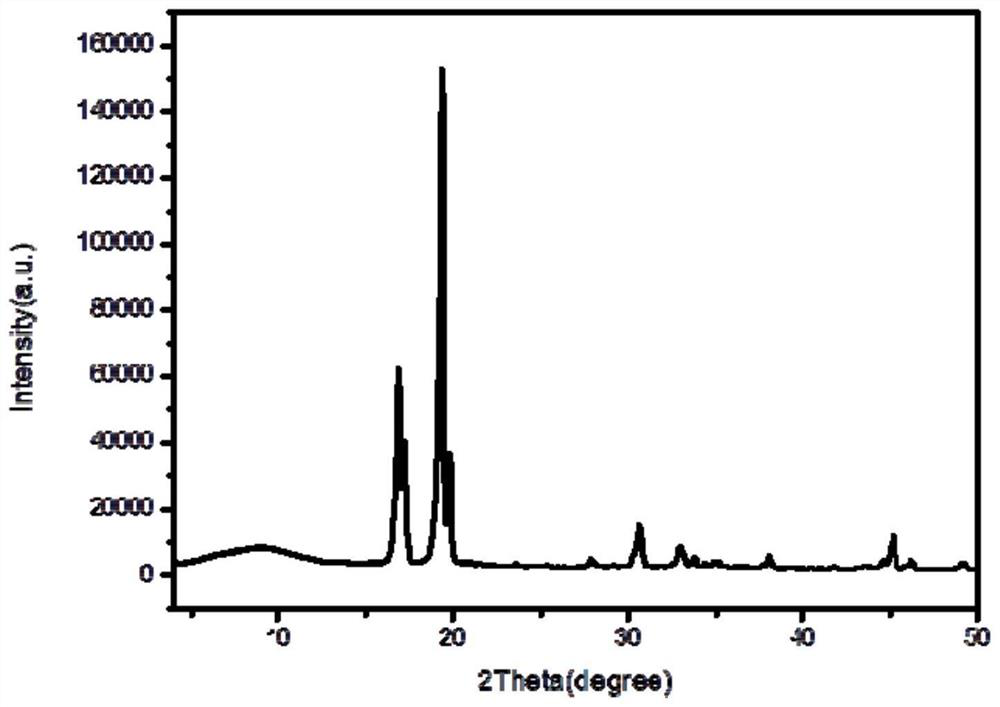

[0036] The X-ray diffraction pattern of gained triethylenediamine product is as figure 1As shown, the X-ray diffraction patterns are at diffraction angles 2θ=16.86, 17.19, 19.30, 19.82, 27.91, 30.64, 33.00, 33.80, 34.88, 35.14, 38.08, 44.64, 45.14, 46.19, 49.08, 52.50, 54.01, 58...

Embodiment 2

[0041] Add 1200g of triethylenediamine and 646g of absolute ethanol into the MSMPR crystallizer, under the action of stirring, dissolve completely at 60°C, then control the fluid linear velocity to 30cm / s, and cool down at 0.01°C / min~0.2°C / min The rate is gradually lowered to 20°C, and the temperature is kept constant for 30 minutes, in which the temperature is lowered at 0.01°C / min within the cooling range of 45°C to 30°C, and finally the crystal slurry is suction-filtered, and the obtained solid wet material is dried at 45°C and 30KPa for 2 hours. Then use a standard sieve to sieve to obtain the triethylenediamine product.

[0042] The X-ray diffraction spectrum of gained triethylenediamine product is at diffraction angle 2θ=16.90,17.02,19.36,19.87,27.81,30.71,33.00,33.72,34.81,35.11,38.12,44.54,45.22,46.16,49.15,52.46,54.10 , 58.50, 60.13, 62.81, 63.75, 71.59, 76.58 degrees have obvious characteristic peaks, and the relative intensity of each diffraction peak is 40.0%, 23.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com