High-temperature self-crosslinking waterborne polyurethane resin containing epoxy group as well as preparation method and application of high-temperature self-crosslinking waterborne polyurethane resin

A water-based polyurethane and epoxy group technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of low introduction of epoxy groups and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

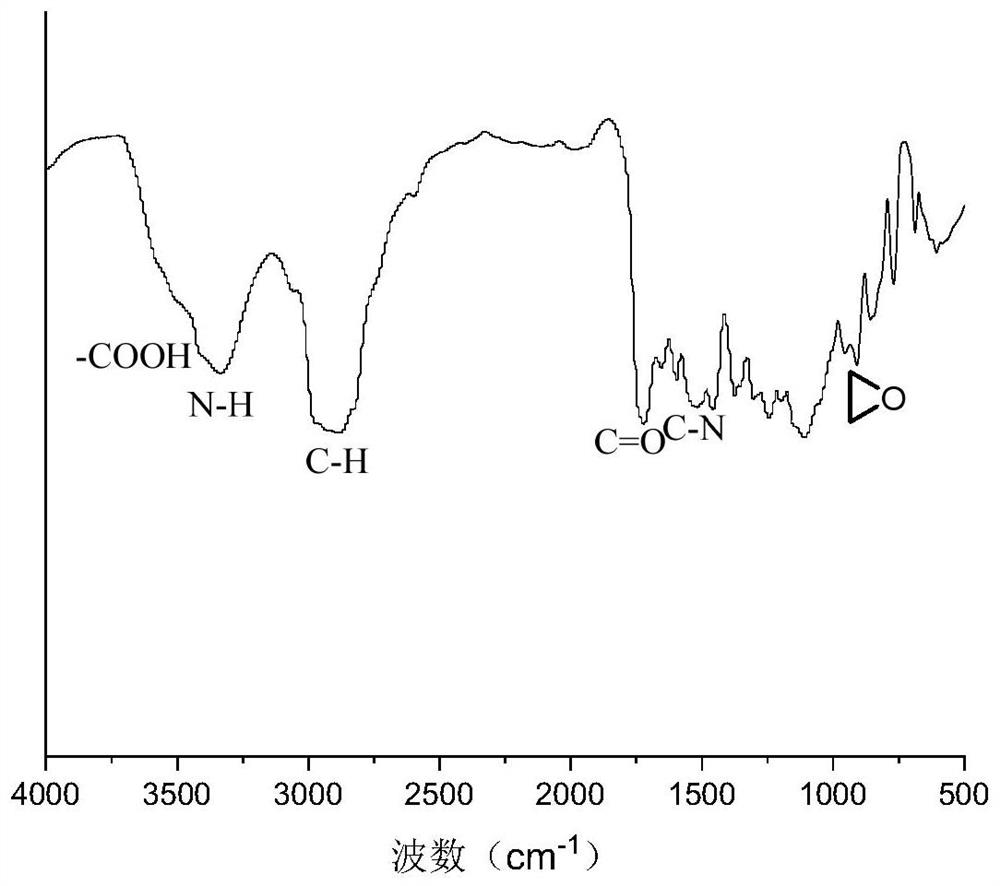

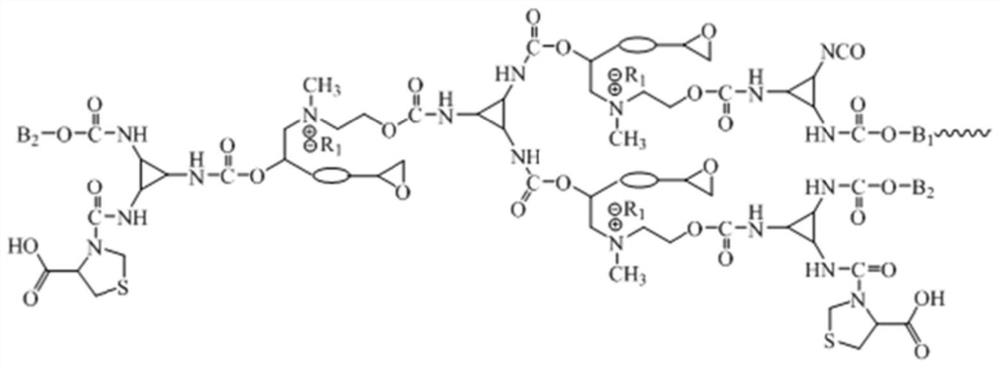

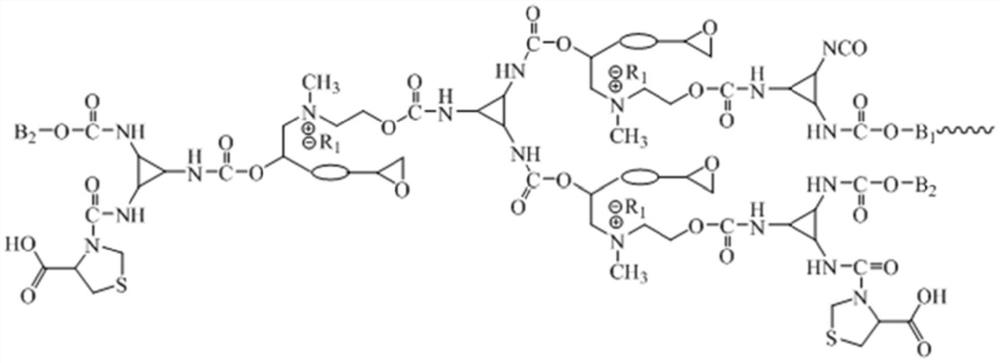

Method used

Image

Examples

Embodiment 1

[0027] The following are expressed in parts by mass. Under the protection of nitrogen and mechanical stirring throughout the whole process, 16.0 parts of diethylene glycol diethyl ether and 11.0 parts of ethylene glycol diglycidyl ether were added to a four-necked flask and stirred evenly. Next, add 3.0 parts of diethylene glycol diethyl ether and 2.0 parts of N-methylethanolamine within 0.5 hours, after the heat preservation reaction for 0.4 hours, add 1.0 parts of formic acid within 0.2 hours, after heat preservation reaction for 0.5 hours, add 6.0 parts of Diethylene glycol diethyl ether and 15.0 parts of hexamethylene diisocyanate trimer were reacted at 45°C for 1.0h, and then 3.0 parts of polyethylene glycol 400 and 11.5 parts of polyethylene glycol monomer were added within 0.2h. Methyl ether 1500, heat preservation reaction at 75°C for 1.0h, then cool down, add 3.7 parts of 1,3-thiazoline-4-carboxylic acid within 0.5h under ice bath conditions, and heat preservation reac...

Embodiment 2

[0033] Under nitrogen protection and mechanical stirring, 17.0 parts of hexanediol dimethyl ester and 12.5 parts of 1,6-hexanediol diglycidyl ether were added to a four-necked flask and stirred evenly. Add 5.0 parts of hexanediol dimethyl ester and 2.8 parts of N-methylethanolamine, after the heat preservation reaction for 1.0h, add 1.4 parts of glacial acetic acid in 0.2h, after heat preservation reaction for 1.0h, add 5.0 parts of diethylene glycol Diethyl ether and 18.5 parts of isophorone diisocyanate trimer were incubated at 50°C for 1.5 hours, and then 5.0 parts of polyethylene glycol 600 and 10.0 parts of polyethylene glycol monomethyl ether 2000 were added within 0.5 hours. Cool down at 65°C for 1.5 hours, then add 2.5 parts of 1,3-thiazoline-4-carboxylic acid within 0.5 hours under ice bath conditions, and heat for 1.0 hours to obtain a It is a water-based polyurethane resin capable of self-crosslinking at high temperatures.

[0034] The storage time at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com