Antibacterial environment-friendly tableware and preparation method thereof

A tableware and environmental protection technology, applied in the field of material processing, can solve the problems of increasing food storage time and poor mechanical properties of tableware, and achieve the effect of good mechanical properties, excellent mechanical properties, and accelerated degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

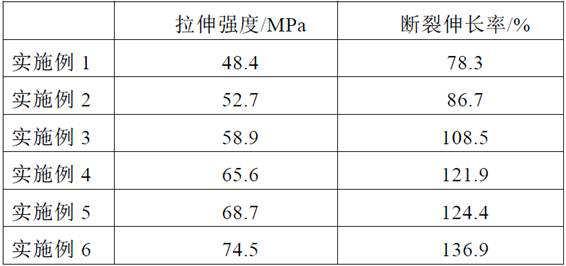

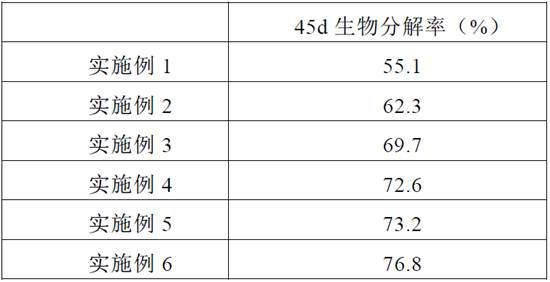

Examples

Embodiment 1

[0046] An antibacterial environment-friendly tableware is composed of the following raw materials in parts by weight: 70 parts by weight of polylactic acid, 10 parts by weight of gum arabic, 2.5 parts by weight of sodium bicarbonate, 20 parts by weight of polyvinyl alcohol, 15 parts by weight of poly 3-hydroxybutyrate, 4 parts by weight of calcium stearate, 2 parts by weight of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 25 parts by weight of inorganic filler, and 15 parts by weight of water.

[0047] Described inorganic filler is talcum powder;

[0048] A kind of preparation method of antibacterial environment-friendly tableware is as follows:

[0049] S1, take each component raw material by weight;

[0050] S2, polylactic acid, gum arabic, sodium bicarbonate, polyvinyl alcohol, poly 3-hydroxybutyrate, calcium stearate, 3-(2,3-glycidyloxy) propyltrimethoxysilane, talc Mix powder and water, and stir at 50°C and 400rpm for 10 minutes to obtain a mixed slurry;

[0051] S3. In...

Embodiment 2

[0054] An antibacterial environment-friendly tableware is composed of the following raw materials in parts by weight: 70 parts by weight of polylactic acid, 10 parts by weight of gum arabic, 2.5 parts by weight of sodium bicarbonate, 20 parts by weight of polyvinyl alcohol, 15 parts by weight of poly 3-hydroxybutyrate, 4 parts by weight of calcium stearate, 2 parts by weight of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 25 parts by weight of inorganic filler, and 15 parts by weight of water.

[0055] Described inorganic filler is modified talcum powder;

[0056] The preparation method of the modified talc powder is as follows: (1) Preparation of the modified talc powder emulsion: take 20 parts by weight of pea starch, 40 parts by weight of talcum powder, and 100 parts by weight of water, mix them, and stir at 500 rpm for 30 minutes to form a suspension solution; put it under ultrasonic power of 400W and ultrasonic frequency of 45kHz for 40min, then gelatinize at 85°C for 2.5h...

Embodiment 3

[0064] An antibacterial environment-friendly tableware is composed of the following raw materials in parts by weight: 70 parts by weight of polylactic acid, 10 parts by weight of gum arabic, 2.5 parts by weight of sodium bicarbonate, 20 parts by weight of polyvinyl alcohol, 15 parts by weight of poly 3-hydroxybutyrate, 4 parts by weight of calcium stearate, 2 parts by weight of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 25 parts by weight of inorganic filler, and 15 parts by weight of water.

[0065] Described inorganic filler is modified talcum powder;

[0066] The preparation method of the modified talcum powder is as follows: (1) Preparation of modified starch: 30 parts by weight of pea starch and 70 parts by weight of water were mixed, stirred at 400rpm for 5min, and the pH was adjusted with 1mol / L aqueous sodium hydroxide solution. 10. Add 2 parts by weight of glycerin and 6 parts by weight of itaconic anhydride, stir in a nitrogen atmosphere at 70°C and 400rpm for 2h to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com