High-performance carbon/carbonate heat transfer and storage medium, phase change heat storage composite material and preparation method of high-performance carbon/carbonate heat transfer and storage medium

A heat storage medium, phase change heat storage technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of phase separation, uneven dispersion, etc., to reduce the degree of phase separation, uniform dispersion, and easy access to raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

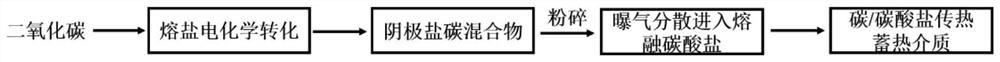

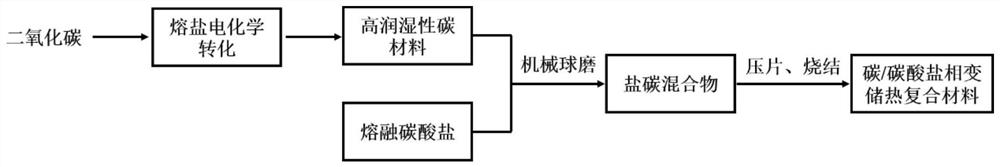

[0041] Preparation of carbon / carbonate heat transfer heat storage medium, the steps are as follows:

[0042] (1) Preparation of molten salt electrochemical preparation of cathode salt-carbon mixture: aeration of carbon dioxide into the molten carbonate electrolyte, while inserting the cathode and anode electrodes, electrified electrolysis to obtain the cathode salt-carbon mixture;

[0043] (2) Grinding the cathode salt-carbon mixture into powder, heating and melting;

[0044] (3) Pass an inert gas into the molten carbonate for protection, then add the molten cathode salt-carbon mixture in step (2), and continue to ventilate until a uniform carbon / carbonate heat transfer and heat storage medium is formed.

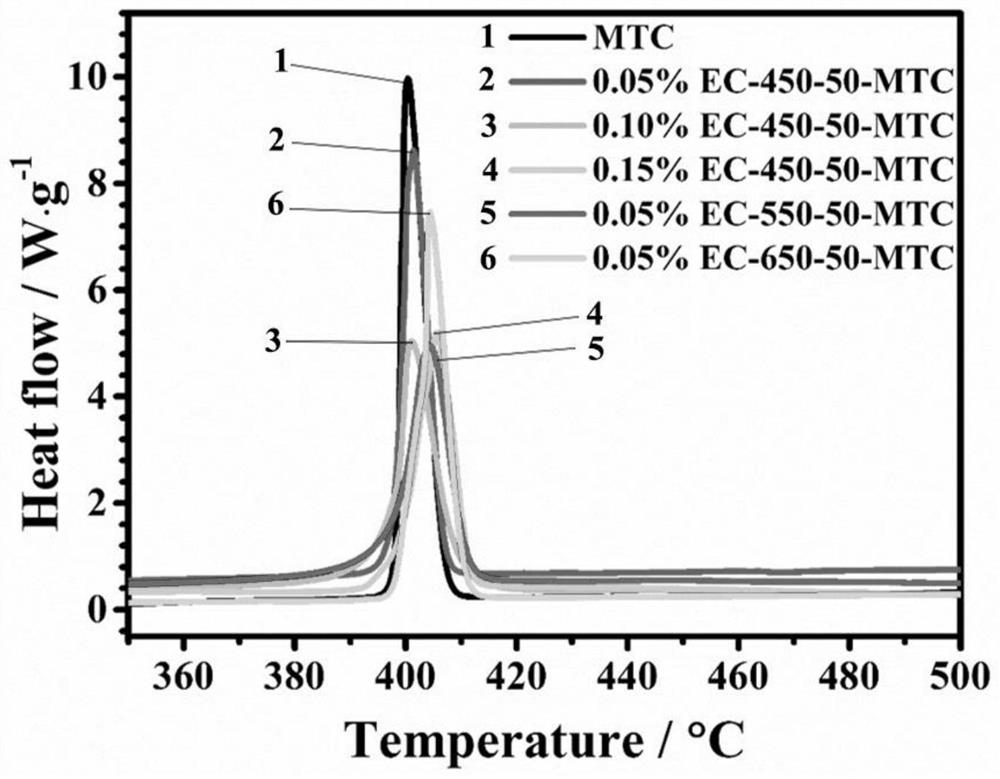

[0045] In this example, at 450°C, with 50mA·cm -2 The cathode salt-carbon mixture was prepared by electrolysis, wherein the mass fraction of the electrolytic carbon material was 2.25%. Accurately weigh 2.22 g of the cathode salt-carbon mixed product prepared under this con...

Embodiment 2

[0049] Prepare carbon / carbonate heat transfer heat storage medium, method is the same as embodiment 1, specifically as follows:

[0050] At 450°C, at 50mA·cm -2 The cathode salt-carbon mixture was prepared by electrolysis, wherein the mass fraction of the electrolytic carbon material was 2.25%. Accurately weigh 4.44g of the cathode salt-carbon mixed product prepared under this condition, and in 100mL min -1 Ar flowed down, uniformly dispersed in 95.56g of molten ternary carbonate, and continued to mix for 60min to obtain a carbon material mass fraction of 0.10% uniformly dispersed carbon / carbonate heat transfer and heat storage medium.

[0051] Specific heat capacity and conductivity test:

[0052] Measure the specific heat capacity of the product of this example at 450°C, 475°C and 500°C to be 2.36J·g respectively -1 ·K -1 , 2.20J·g -1 ·K -1 and 2.01J g -1 ·K -1 , with an average value of 2.19J g -1 ·K -1 , an increase of 31.14% compared with pure molten carbonate; ...

Embodiment 3

[0054] Prepare carbon / carbonate heat transfer heat storage medium, method is the same as embodiment 1, specifically as follows:

[0055] At 450°C, at 50mA·cm -2 The cathode salt-carbon mixture was prepared by electrolysis, wherein the mass fraction of the electrolytic carbon material was 2.25%. Accurately weigh 6.67g of the cathode salt-carbon mixed product prepared under this condition, and in 100mL min -1 Ar flowed down, uniformly dispersed in 93.33g of molten ternary carbonate, and continued to mix for 60min to obtain a uniformly dispersed carbon / carbonate heat transfer and heat storage medium with a carbon material mass fraction of 0.15%.

[0056] Specific heat capacity and conductivity test:

[0057] Measure the specific heat capacity of the product of this example at 450°C, 475°C and 500°C to be 2.25J·g respectively -1 ·K -1 , 2.12J·g -1 ·K -1 and 2.08J g -1 ·K -1 , with an average value of 2.15J g -1 ·K -1 , an increase of 28.74% compared with pure molten carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com