System for preparing propionate through ethylene carbonylation

A technology for preparing propionate and carbonylation, which is applied in the separation/purification of carboxylate, carbon monoxide or formate reaction preparation, carboxylate preparation, etc. Pipeline clogging and other problems, to achieve the maximum separation, increase the reaction rate and enhance the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

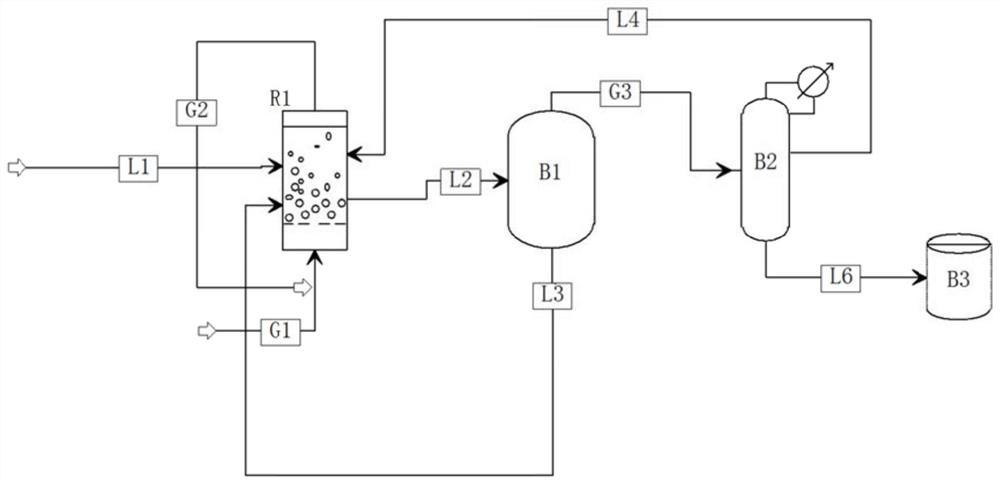

[0049] A system for the carbonylation of ethylene to propionates, such as figure 1 As shown, including the bubbling reactor R1 and the separation and refining unit, the gas phase reaction raw material G1 and the liquid phase reaction raw material L1 for the preparation of the propionate product L6 are carbonylated in the bubbling reactor R1, and the generated product containing propane The ester material L2 is separated and purified by the separation and refining unit to obtain the propionate product L6. In this embodiment, the material L2 containing propionate preferably enters the separation and refining unit through the side line of the bubbling reactor R1. In this embodiment, it is further preferred that the separation and refining unit includes a flash tower B1 connected to the side line of the bubble reactor R1 and using a side feed, and a flash tower B1 connected to the top of the flash tower B1 and using a side feed. Feed refining column B2.

[0050] More specificall...

Embodiment 2

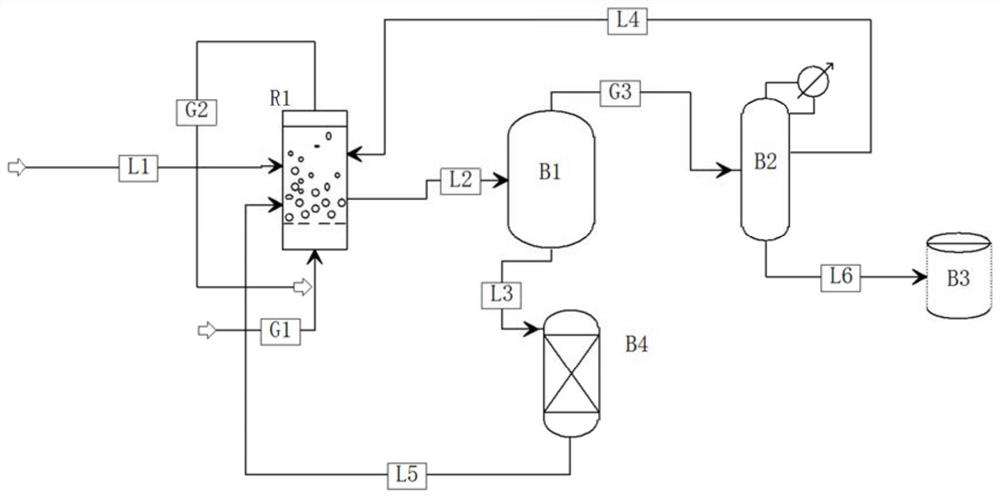

[0060] A system for the carbonylation of ethylene to propionates, such as figure 2 As shown, including the bubbling reactor R1 and the separation and refining unit, the gas phase reaction raw material G1 and the liquid phase reaction raw material L1 for the preparation of the propionate product L6 are carbonylated in the bubbling reactor R1, and the generated product containing propane The ester material L2 is separated and purified by the separation and refining unit to obtain the propionate product L6. In this embodiment, the material L2 containing propionate preferably enters the separation and refining unit through the side line of the bubbling reactor R1. In this embodiment, it is further preferred that the separation and refining unit includes a flash tower B1 connected to the side line of the bubble reactor R1 and using a side feed, and connected to the top of the flash tower B1 and using a side feed. Feed refining column B2 and a membrane-based solid-liquid separator...

Embodiment 3

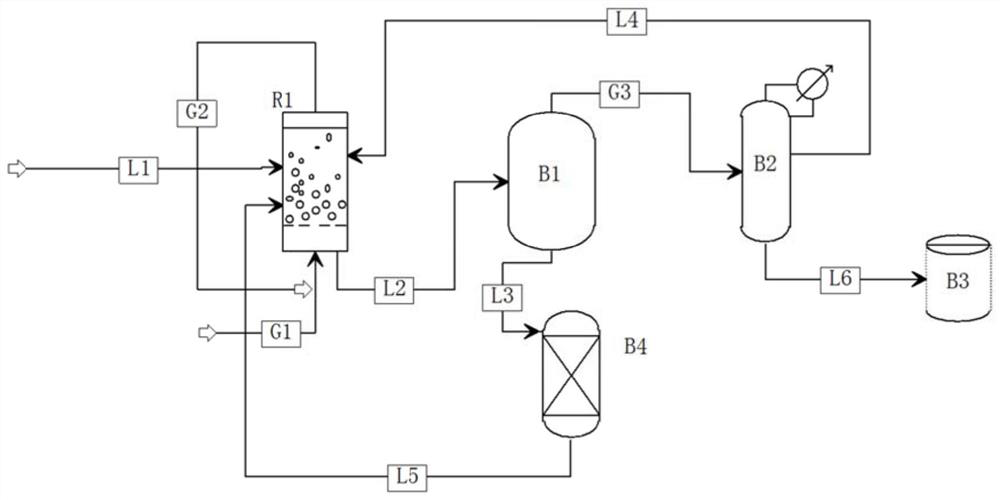

[0072] This embodiment is basically the same as Embodiment 2, the difference is that 1) in this embodiment, the material L2 containing propionate enters the separation and refining unit through the bottom end of the bubbling reactor R1, such as image 3 Shown; 2) in the present embodiment, the technology of ethylene carbonylation continuous methyl propionate, adopts above-mentioned system, comprises the following steps:

[0073]S1: The gas-phase reaction raw material G1 and the liquid-phase reaction raw material L1 enter the bubbling reactor R1 respectively, and react at a reaction temperature of 160°C and an operating pressure of 2.0 MPa. The volume ratio of carbon monoxide and ethylene in the gas phase reaction raw material G1 is 10:1, and the supply rate of CO is 1.5NL / min. The liquid-phase reaction raw material L1 is a low-carbon alcohol solution containing a catalyst system, and the catalyst system adopts a homogeneous catalyst system composed of palladium acetate, triphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com