Modified copper phthalocyanine, preparation method, application and blue electronic ink

A technology of electronic ink and copper phthalocyanine, which is applied in the field of electrophoretic display materials, can solve the problems of little research on modification, and achieve excellent dispersion stability and electrophoretic performance, great practical application potential, good chromaticity and density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

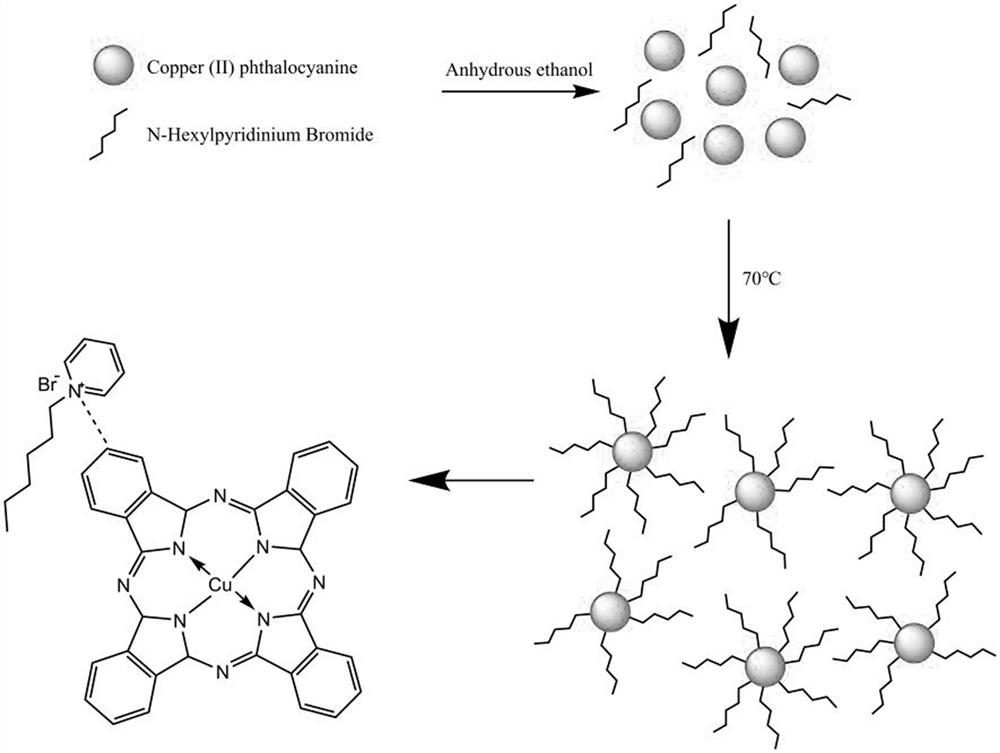

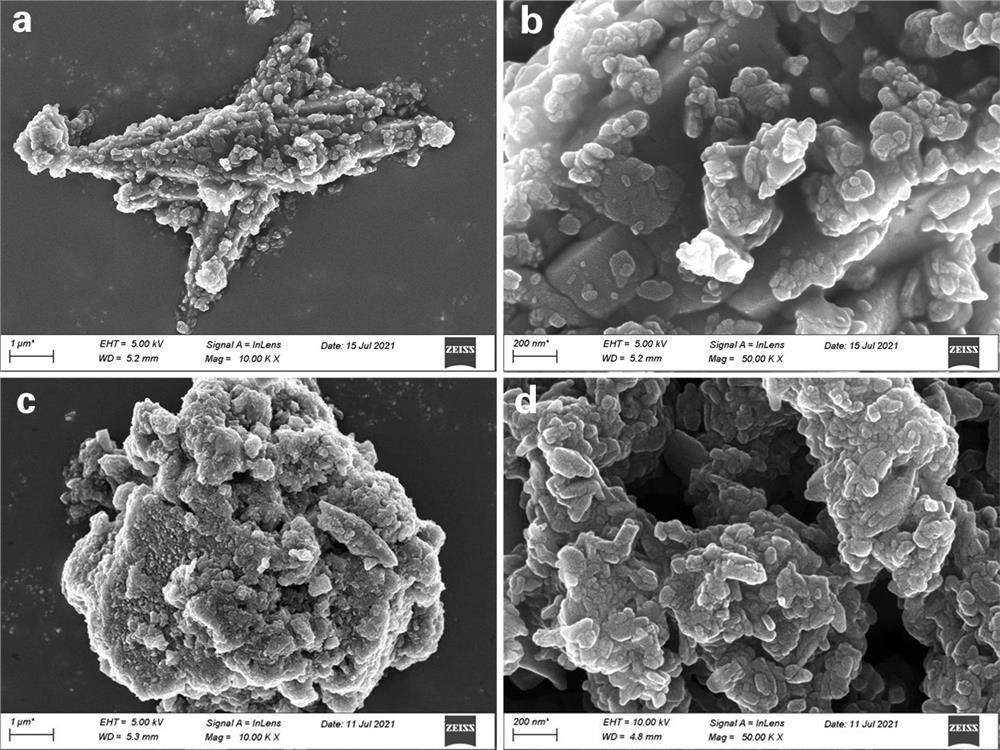

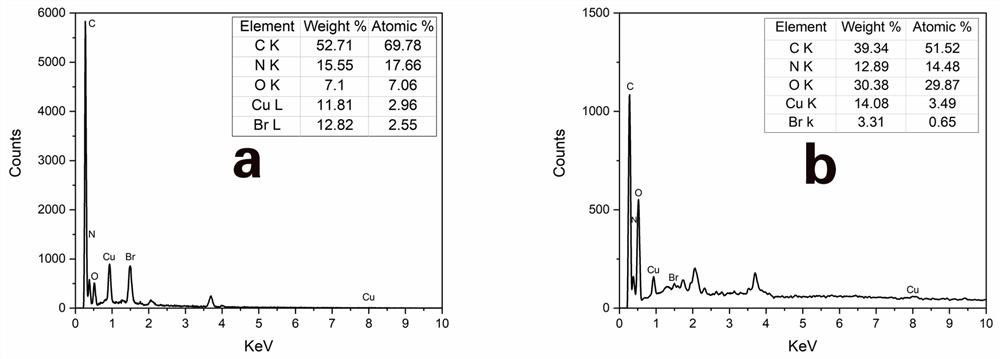

[0036] The preparation method of the modified copper phthalocyanine, the steps are as follows: take a flask, add the above-mentioned absolute ethanol, pyridine ionic liquid and copper phthalocyanine in parts by weight, and then place the flask in an ultrasonic disperser for ultrasonic dispersion , the ultrasonic dispersion time is 10-15min, and the dispersion A is obtained; the dispersion A is placed in a stirring device, and the temperature is raised to 70-75°C while stirring. -2 hours, then cooled to room temperature to obtain dispersion B; place dispersion B in a vacuum desiccator to remove ethanol in dispersion B to obtain modified copper phthalocyanine.

[0037] A blue electronic ink using modified copper phthalocyanine as described above, the preparation raw material components and parts by weight of the ink are as follows: 0.1-0.3 parts of modified copper phthalocyanine (CP-IL); non-polar medium (using Tetrachloroethylene, the molecular formula is C 2 Cl 4 , purchased f...

specific Embodiment 1

[0046] Specific example 1: absolute ethanol 50ml (obtained by conversion of 50 parts by weight), 0.1 g of 1-hexylpyridinium bromide (obtained by conversion of 0.1 parts by weight), CP0.5g (obtained by conversion of 0.5 parts by weight) , 0.2g of CP-IL (obtained by conversion of 0.2 parts by weight), 0.2g of Span80 (obtained by conversion of 0.2 parts by weight) and 10ml of TCE (obtained by conversion of 10 parts by weight). Among them, CP-IL is CP modified by 1-hexylpyridinium bromide. In the specific preparation process, the CP needs to be modified first, and then the above weight parts of CP-IL are weighed.

[0047] The preparation steps of specific embodiment 1:

[0048] (1) Surface modification of CP by ionic liquid: 50ml of absolute ethanol and 0.1g of 1-hexylpyridinium bromide were added to a 100ml flask containing 0.5g of CP, and ultrasonically vibrated for 10 minutes. The mixture was stirred at 70°C for 1.5 hours, then ethanol was removed at 50°C with a vacuum drier. ...

specific Embodiment 2

[0050] Specific embodiment 2: absolute ethanol 50ml (obtained through 50 parts by weight conversion), 1-butyl-1-methylpyrrolidine bromide 0.1g (obtained through 0.1 parts by weight conversion), CP0.5g (obtained through 0.5 parts by weight) CP-IL 0.2g (obtained by converting 0.2 parts by weight), Span80 0.2g (obtained by converting 0.2 parts by weight) and TCE 10ml (obtained by converting 10 parts by weight). Among them, CP-IL is the CP modified by 1-butyl-1-methylpyrrolidine bromide. In the specific preparation process, it is necessary to modify the CP first, and then weigh the CP-IL of the above parts by weight. IL.

[0051] The preparation steps of specific embodiment 2:

[0052] (1) Surface modification of CP by ionic liquid: 50ml of absolute ethanol and 0.1g of 1-butyl-1-methylpyrrolidine bromide were added to a 100ml flask containing 0.5g of CP, and ultrasonically vibrated for 10 minutes. The mixture was stirred at 70°C for 1.5 hours, then ethanol was removed at 50°C wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com