Method for preparing hafnium oxide film by chemical liquid phase deposition method

A chemical liquid deposition, hafnium oxide technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of no reports, and achieve low cost, good leakage, high transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

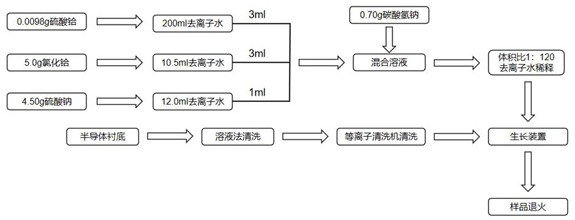

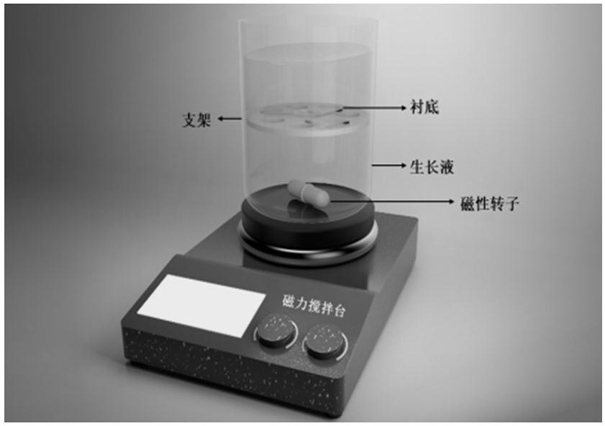

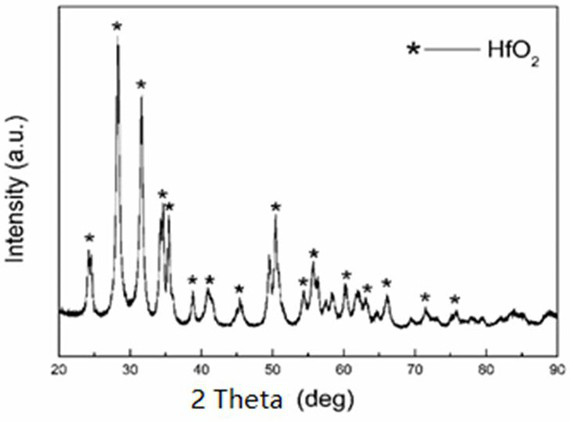

[0042] A method for preparing a hafnium oxide thin film by chemical liquid phase deposition, comprising the following steps:

[0043] (1) Put the indium phosphide substrate into acetone and ultrasonically clean it for 15 minutes, then put it in absolute ethanol for 15 minutes, then put it into deionized water and ultrasonically clean it for 15 minutes, and blow dry it with nitrogen after taking it out;

[0044] (2) Put the cleaned indium phosphide substrate into a plasma cleaning machine for cleaning, set the working voltage to 625V, set the working current to 10mA, and set the time to 10min;

[0045] (3) Weigh 0.0098 g Hf(SO 4 ) 2 powder, dissolved in 200 ml deionized water at room temperature, Hf(SO 4 ) 2 The solubility in aqueous solution is extremely low, so a very small amount of Hf(SO 4 ) 2 The powder can make the solution reach saturation;

[0046] (4) Weigh 5.0g HfCl 4 The powder was slowly dissolved in 10.5 ml deionized water, HfCl in a fume hood 4 The reactio...

Embodiment 2

[0057] A method for preparing a hafnium oxide thin film by chemical liquid phase deposition, comprising the following steps:

[0058] (1) Put the quartz glass substrate into acetone and ultrasonically clean it for 15 minutes, then put it in absolute ethanol for ultrasonic cleaning for 15 minutes after taking it out, then put it into deionized water and ultrasonically clean it for 15 minutes, and blow it dry with nitrogen after taking it out;

[0059] (2) Put the cleaned quartz glass substrate into a plasma cleaning machine for cleaning, set the operating voltage to 625V, the operating current to 10mA, and the time to 10min;

[0060] (3) Weigh 0.0098 g Hf(SO 4 ) 2 powder, dissolved in 200 ml deionized water at room temperature, Hf(SO 4 ) 2 The solubility in aqueous solution is extremely low, so a very small amount of Hf(SO 4 ) 2 The powder can make the solution reach saturation;

[0061] (4) Weigh 5.0g HfCl 4 The powder was slowly dissolved in 10.5 ml deionized water, Hf...

Embodiment 3

[0070] A method for preparing a hafnium oxide thin film by chemical liquid phase deposition, comprising the following steps:

[0071] (1) Put the silicon substrate into acetone and ultrasonically clean it for 15 minutes, then put it in absolute ethanol for ultrasonic cleaning for 15 minutes after taking it out, put it into deionized water for ultrasonic cleaning for 15 minutes after taking it out, and dry it with nitrogen after taking it out;

[0072] (2) Put the cleaned silicon substrate into a plasma cleaning machine for cleaning, set the working voltage to 625V, set the working current to 10mA, and set the time to 10min;

[0073] (3) Weigh 0.0098 g Hf(SO 4 ) 2 powder, dissolved in 200 ml deionized water at room temperature, Hf(SO 4 ) 2 The solubility in aqueous solution is extremely low, so a very small amount of Hf(SO 4 ) 2 The powder can make the solution reach saturation;

[0074] (4) Weigh 5.0g HfCl 4 The powder was slowly dissolved in 10.5 ml deionized water, Hf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com