Light emitting diode epitaxial wafer and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reducing the luminous efficiency of LED epitaxial wafers, achieve the effects of improving bending and tilting phenomena, increasing luminous efficiency, and alleviating polarization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

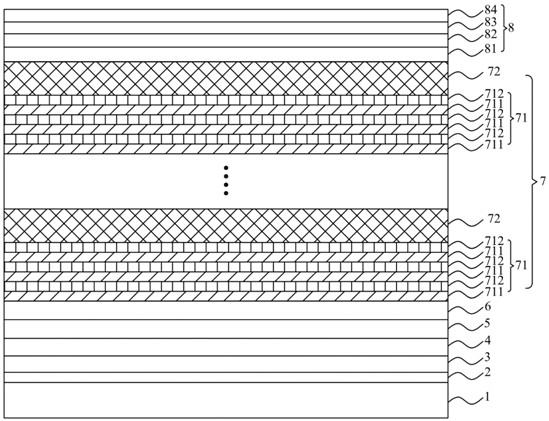

[0038] see figure 1 , is a schematic structural view of a light-emitting diode epitaxial wafer provided by an embodiment of the present invention. For convenience of description, only the parts related to the embodiment of the present invention are shown. The light-emitting diode epitaxial wafer provided by the embodiment of the present invention includes a substrate 1, And a buffer layer 2, a three-dimensional nucleation layer 3, a two-dimensional recovery layer 4, an undoped GaN layer 5, an N-type GaN layer 6, a multi-quantum well layer 7 and a P-type layer 8 sequentially stacked on the substrate 1; Wherein the multi-quantum well layer 7 includes x periodically alternately arranged mixed-polarity quantum well layers 71 and quantum barrier layers 72; the mixed-polarity quantum well layer 71 includes y periodically alternately arranged N-polar surface quantum wells Layer 711 and Ga polar surface quantum well layer 712.

[0039] Wherein, in one embodiment of the present invent...

Embodiment 2

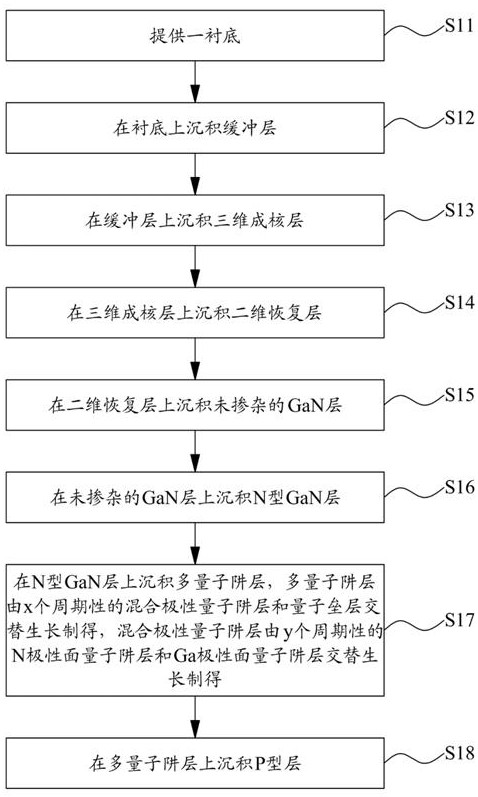

[0050] see figure 2 , shows the method for preparing a light-emitting diode epitaxial wafer in the second embodiment of the present invention, and the method specifically includes steps S11 to S18.

[0051] Step S11, providing a substrate.

[0052] Among them, in the embodiment of the present invention, the selected substrate can be any one of a sapphire substrate, a silicon substrate, a silicon carbide substrate, and a gallium nitride substrate. Specifically, in this embodiment, sapphire is used as the Epitaxial layer growth substrate.

[0053] Further, the present invention adopts metal organic chemical vapor deposition (MOCVD) equipment to grow epitaxial wafers. Among them, high-purity ammonia gas (NH 3 ) as N (nitrogen) source, trimethylgallium (TMGa) and triethylgallium (TEGa) as Ga (gallium) source, trimethylindium (TMIn) as In (indium) source, trimethylaluminum (TMAl ) as the Al (aluminum) source, where silane (SiH 4 ) as an N-type dopant, magnesiumocene (CP 2 Mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com