Preparation method of mixed fluid glass chip

A technology of glass chips and mixed fluids, applied in chemical instruments and methods, manufacturing tools, metal processing equipment, etc., can solve problems such as chipping, limited processing, and affecting the quality of structural edges, so as to ensure bonding tightness, Reduce processing difficulty, improve surface smoothness and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment one: a kind of preparation method of mixed fluid glass chip, comprises the following steps:

[0056] S1. Simulation structure segmentation step

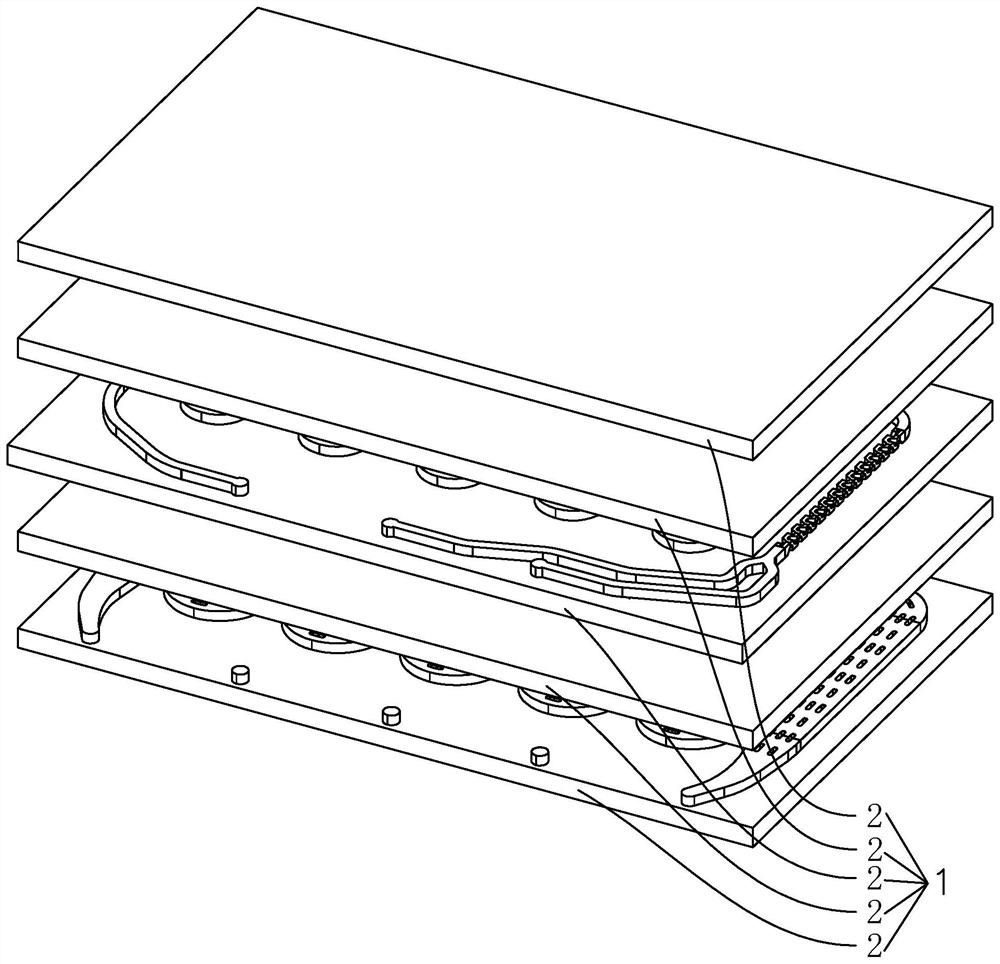

[0057] S1.1. Design and finalize the fluid chip 1 through three-dimensional software to ensure that the flow channel meets the design requirements.

[0058] S1.2. Simulate and divide each layer structure 2 along the thickness direction of the designed and finalized fluid chip. The division requirement is to reduce the internal hollow structure of each layer structure 2 under the premise of avoiding independent components.

[0059] S2, single-layer glass preparation steps

[0060] S2.1. According to the specific structure and processing requirements of each layer structure 2, select a glass plate material with an appropriate size, and process the glass plate material by etching.

[0061] Etching processing method is ultrafast laser processing, which includes the following steps:

[0062] S2.1a.1. Write the control...

Embodiment 2

[0080] Embodiment 2: The difference between this embodiment and Embodiment 1 lies in the difference in etching method and processing method.

[0081] The etching processing method is an anisotropic wet etching processing, which includes the following steps:

[0082] S2.1b.1. Fully clean the surface of the selected flat glass material to remove organic and inorganic impurities, and place the flat glass material in a plasma cleaning machine for surface treatment.

[0083] S2.1b.2. Place the surface-treated glass plate material in an ultra-clean environment, and cover the surface with a mask material, which is any one of photoresist, metal film or semiconductor film.

[0084] S2.1b.3. Place the glass plate material under the laser system, place the structure with the mask facing the laser, fix the lower surface, focus the laser on the mask, and then scan and remove part of the mask material according to the designed structure , finally forming a mask pattern;

[0085] S2.1b.4. ...

Embodiment 3

[0087] Embodiment 3: The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the difference of etching method and processing method.

[0088] The etching processing method is a dry etching processing, which includes the following steps:

[0089] S2.1c.1. Fully clean the surface of the selected glass plate material to remove organic and inorganic impurities, and place the glass plate material in a plasma cleaning machine for surface treatment.

[0090] S2.1c.2. Place the surface-treated glass plate material in an ultra-clean environment, and cover its surface with a mask material.

[0091] S2.1c.3. Process a mask pattern on the mask material by using photolithography or laser scanning.

[0092] S2.1c.4. Use low-pressure reactive ion beam or electron beam to bombard the surface of the glass plate material, the area not covered by the mask material is etched and removed, and the area covered by the mask material is protected and will not be removed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com