Biomass pretreatment method and application

A biomass and pretreatment technology, applied in the direction of fermentation, etc., can solve problems such as obstacles to the effective use of lignocellulosic biomass, overall structural complexity, etc., and achieve the effects of reducing costs and energy consumption, mild conditions, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for pretreatment of biomass, comprising the steps of:

[0044] 1) Crushing and screening of eucalyptus raw materials:

[0045] After pulverizing the eucalyptus wood raw material, passing through a 60-100 mesh sieve to obtain eucalyptus wood powder;

[0046] 2), benzene alcohol extraction:

[0047] The 60-100-mesh eucalyptus powder obtained after sieving in step 1) was extracted with toluene-ethanol (2:1, v / v) for 8 hours, and then put into an oven for drying at 40°C;

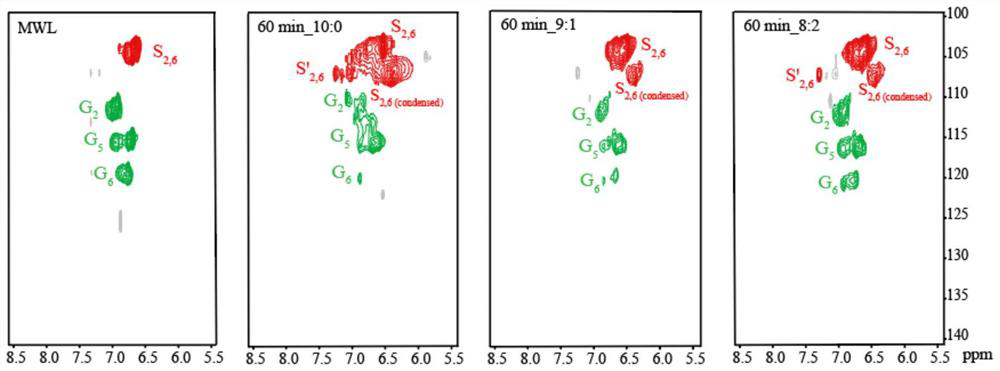

[0048] 3), pretreatment of biomass with isosorbide dimethyl ether / water mixed solution:

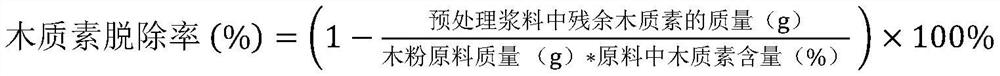

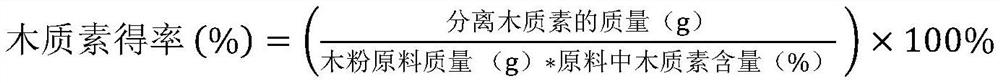

[0049] Take by weighing absolutely dry to be 1.5g the eucalyptus powder that obtains through step 2) in the pressure bottle, add isosorbide dimethyl ether 15ml in the pressure bottle according to the ratio of solid-to-liquid ratio 1:10 (m / v), Then add a certain amount of 67.5 μl 72% H to the pressure bottle 2 SO 4 solution. The entire reaction system was placed at 100° C. for 60 minutes and continuousl...

Embodiment 2

[0058] The temperature in step 3) of Example 1 was increased to 120° C., and other conditions remained unchanged, the quality of recovered lignin was 0.205 g, and the calculated removal rate of lignin was 79.4%, and the yield was 43.8%.

[0059] The efficiency of cellulose hydrolysis and saccharification in cellulose conversion utilization is 8.1%.

Embodiment 3

[0061] Increase the temperature in step 3) of Example 1 to 120°C, change the volume ratio of isosorbide dimethyl ether to water to 9:1 (v / v), and keep other conditions unchanged, then the quality of recovered lignin is 0.237g , the calculated removal rate of lignin is 91.2%, and the yield is 50.6%.

[0062] The efficiency of cellulose hydrolysis and saccharification in cellulose conversion utilization is 82.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com