Lithium nickel cobalt manganese oxide high-nickel single-crystal positive electrode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high capacity, large size and high dispersion, and achieve the effect of enhanced conductivity and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

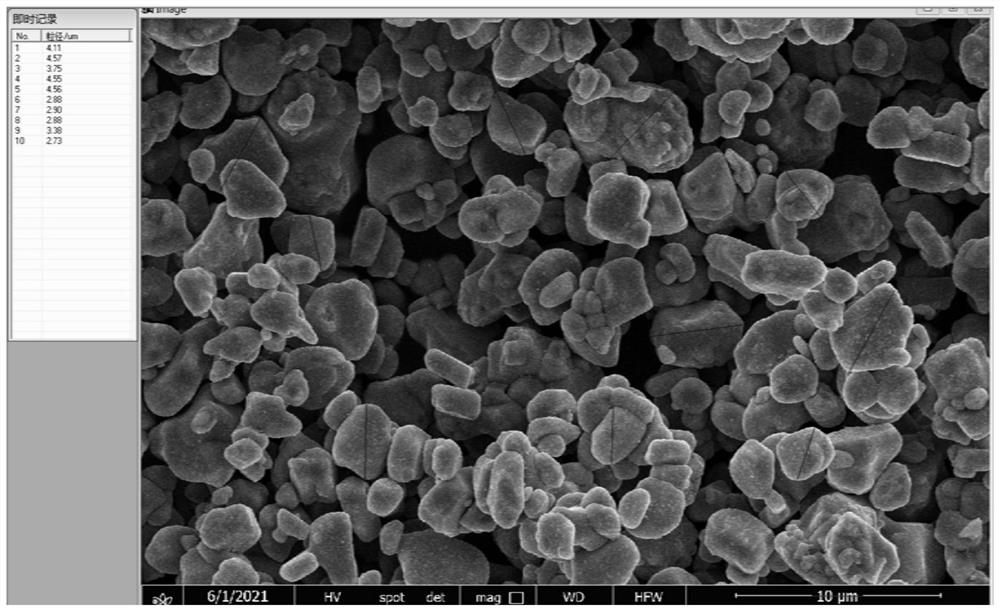

[0019] The first aspect of the present invention provides a method for preparing nickel-cobalt lithium manganate high-nickel single crystal positive electrode material, comprising the following steps:

[0020] S1. Mix and ball-mill nickel-cobalt-manganese hydroxide with lithium source, zirconia, tungsten oxide, and sodium carbonate, and then sinter once to obtain a nickel-cobalt lithium manganese oxide high-nickel single-crystal positive electrode material intermediate after crushing; wherein, once The sintering temperature is 50-150°C higher than the normal sintering temperature;

[0021] S2. Uniformly mixing the nickel-cobalt lithium manganese oxide high-nickel single-crystal positive electrode material intermediate with the coating agent, followed by secondary sintering to obtain nickel-cobalt lithium manganate high-nickel single-crystal positive electrode material.

[0022] In the present invention, tungsten oxide and sodium carbonate are introduced as dopants in a sinteri...

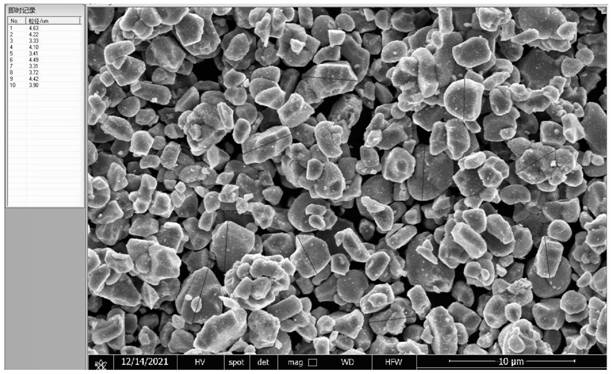

Embodiment 1

[0032] (1) Weigh 2.0kg Ni 0.80 co 0.10 mn 0.10 (OH) 2 Powder, 0.93kg LiOH·H 2 O, 5.78g nano ZrO 2 , 8.10g WO 3 After mixing evenly with 4.95g of sodium carbonate in a ball mill mixer, put the mixture in an oxygen atmosphere furnace for calcination, the calcination temperature is 950°C, and the sintering time is 15h. After the reaction is completed, it is cooled, pulverized, and sieved to obtain nickel Lithium cobalt manganese oxide high nickel single crystal cathode material intermediate;

[0033] (2) 4.65g Y 2 o 3 After being uniformly mixed with the nickel-cobalt lithium manganese oxide high-nickel single crystal positive electrode material intermediate, heat treatment at 500° C. for 10 h in a high oxygen atmosphere to obtain the yttrium-coated nickel-cobalt lithium manganate high nickel single crystal positive electrode material.

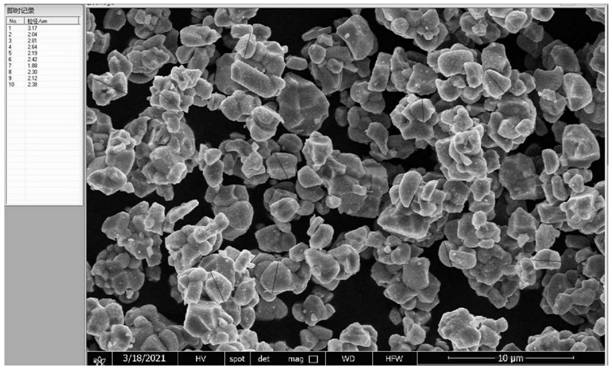

Embodiment 2

[0035] (1) Weigh 2.0kg Ni 0.80 co 0.10 mn 0.10 (OH) 2 Powder, 0.93kg LiOH·H 2 O, 5.78g nano ZrO 2 , 8.10g WO 3 After mixing evenly with 4.95g of sodium carbonate in a ball mill mixer, put the mixture in an oxygen atmosphere furnace for calcination, the calcination temperature is 930°C, and the sintering time is 20h. After the reaction is completed, it is cooled, crushed, and sieved to obtain nickel Lithium cobalt manganese oxide high nickel single crystal cathode material intermediate;

[0036] (2) 4.65g Y 2 o 3 After being uniformly mixed with the nickel-cobalt lithium manganese oxide high-nickel single crystal positive electrode material intermediate, heat treatment at 500° C. for 10 h in a high oxygen atmosphere to obtain the yttrium-coated nickel-cobalt lithium manganate high nickel single crystal positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com