SiC substrate double-pulse femtosecond laser slicing method

A technology of femtosecond laser and femtosecond laser, which is applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of large slice damage thickness, large wafer peeling force, and long processing time, etc. The effect of small damage layer thickness, avoiding a lot of waste, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

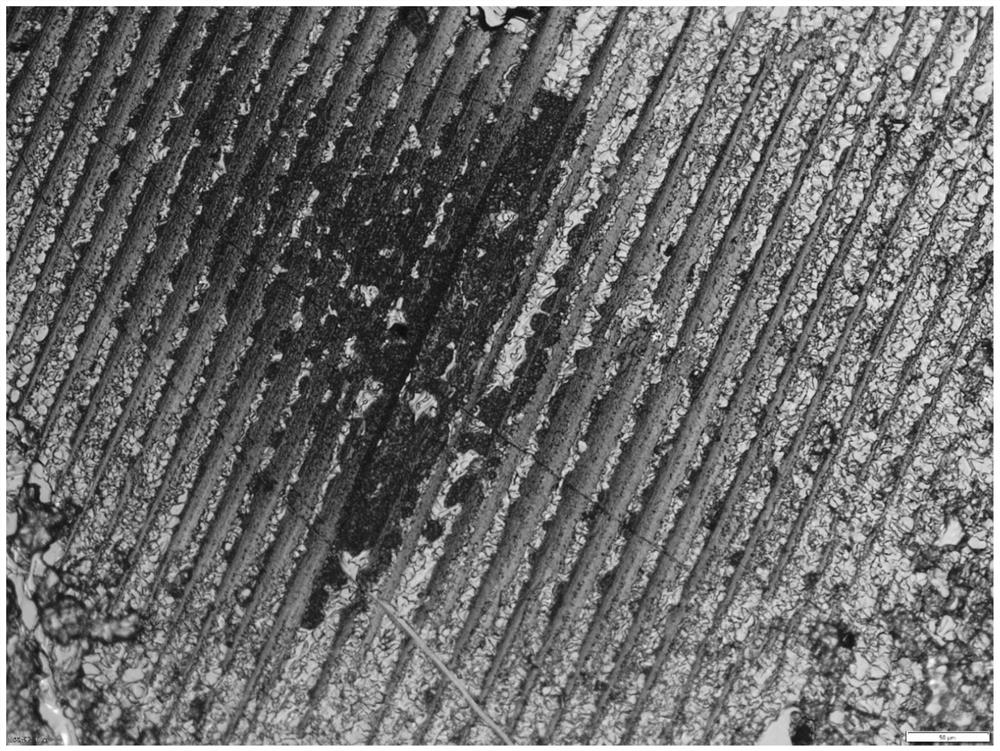

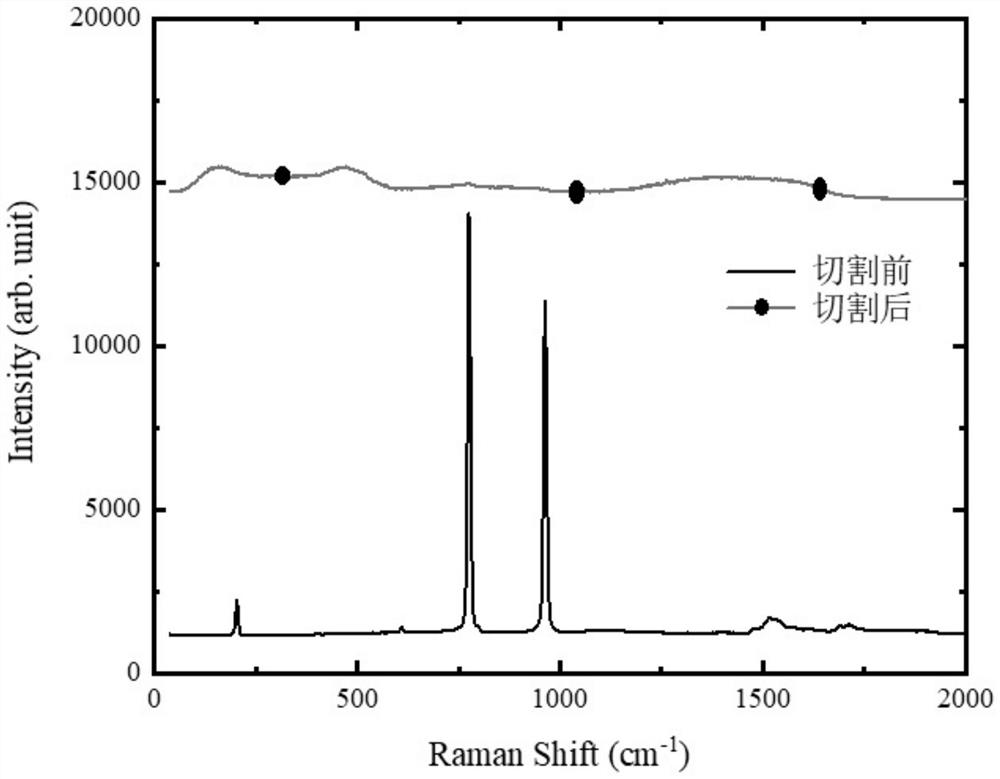

[0035] This embodiment provides a method for double-pulse femtosecond laser slicing of SiC substrates, including the following steps:

[0036] 1) Put the SiC wafer in alcohol for ultrasonic cleaning, remove the surface stains, then dry it, and finally fix it on the laser processing table;

[0037] 2) Adjust the parameters of the femtosecond laser, adjust the parameters to a wavelength of 780nm, a pulse width of 130fs, a pulse energy of 30μJ, a repetition rate of 10kHz, and set the moving speed of the laser processing table to 2mm / s;

[0038] 3) A double-pulse laser is produced by using a double-pulse laser optical circuit device; firstly, a half-wave plate and a polarization beam splitter are used to convert the linearly polarized laser pulse into s- and p-polarized pulses with the same energy; the two pulsed optical paths are introduced into different By precisely controlling the distance traveled by the two optical paths, let them form an optical path difference of 5 ps, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com