Water-based heat-resistant anticorrosive paint with magnetic conductive function and preparation method of water-based heat-resistant anticorrosive paint

An anti-corrosion coating, water-based technology, applied in magnetic coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of coatings without magnetic conductivity, environmental pollution, waste of energy, etc., to enhance the effect of electromagnetic heating and reduce VOC emissions The effect of improving the anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

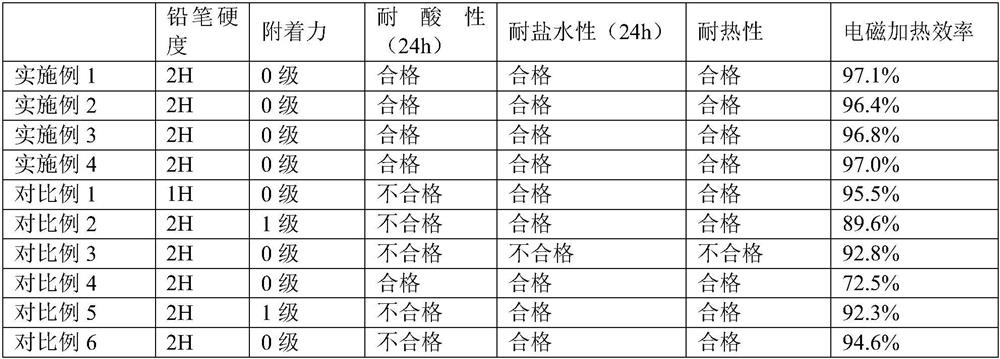

Examples

preparation example Construction

[0038] 1) Preparation of water-based silicone modified polyester resin: put 1-5 parts (parts by mass, the same below) of neopentyl glycol, 10-20 parts of trimethylolpropane, and 10-30 parts of isophthalic acid into In the reaction kettle, heat up to 160-180°C for 1-2 hours of esterification, then raise the temperature to 200-220°C, continue the reaction for 2-4 hours until the acid value drops below 10mgKOH / g and stop the reaction. During the reaction process, 5-10 parts of di Keep reflux of toluene as water-carrying agent, cool down to 140-160°C, add 10-20 parts of ethylene glycol butyl ether and 3-6 parts of trimellitic anhydride, continue the reaction until the acid value is 60-80mgKOH / g, cool down to 110-130°C, Add 0.01-0.02 parts of tetrabutyl titanate and 15-30 parts of organic silicon intermediates, react for 1-2 hours until transparent, then cool down to 80-90°C, add 3-6 parts of N,N-dimethylethanolamine in progress And, finally add 30-60 parts of water to disperse.

...

Embodiment 1

[0043] 1) Preparation of water-based silicone-modified polyester resin: Put 5 parts of neopentyl glycol, 20 parts of trimethylolpropane, and 30 parts of isophthalic acid into the reaction kettle, heat up to 180°C and keep warm for 1 hour for esterification Then raise the temperature to 220°C, continue the reaction for 2 hours until the acid value drops to 8.9mgKOH / g, stop the reaction, keep reflux with 10 parts of xylene as a water-carrying agent during the reaction, cool down to 160°C, add 20 parts of ethylene glycol butyl ether and 6 Trimellitic anhydride, continue to react until the acid value is 68.6mgKOH / g, cool down to 130°C, add 0.02 parts of tetrabutyl titanate and 30 parts of organosilicon intermediate DC-3074, react for 1h until transparent, then cool down to 90°C, add 6 parts of N,N-dimethylethanolamine for neutralization, and finally add 60 parts of water for dispersion.

[0044] 2) Preparation of organically modified anti-corrosion functional filler: After dispers...

Embodiment 2

[0047] 1) Preparation of water-based silicone-modified polyester resin: Put 1 part of neopentyl glycol, 10 parts of trimethylolpropane, and 10 parts of isophthalic acid into the reaction kettle, heat up to 160°C and keep warm for 2 hours to perform esterification Then raise the temperature to 200°C, continue the reaction for 4 hours until the acid value drops to 9.2mgKOH / g, stop the reaction, keep reflux with 5 parts of xylene as a water-carrying agent during the reaction, cool down to 140°C, add 10 parts of ethylene glycol butyl ether and 3 part of trimellitic anhydride, continue to react until the acid value is 72.8mgKOH / g, cool down to 110°C, add 0.01 part of tetrabutyl titanate and 15 parts of organosilicon intermediate DC-3074, react for 2h until transparent, then cool down to 80°C, add 3 parts of N,N-dimethylethanolamine for neutralization, and finally add 30 parts of water for dispersion.

[0048] 2) Preparation of organically modified anti-corrosion functional filler: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com