Quantum dot-MXene fluorescence sensor as well as preparation method and application thereof

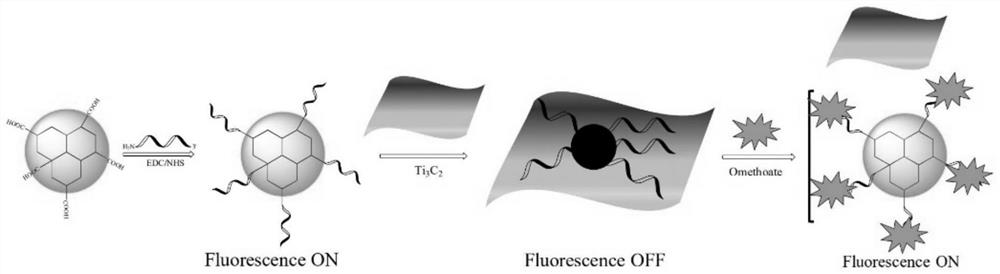

A fluorescent sensor and graphene quantum dot technology, which is applied in the construction and application of chemical sensors, can solve the problems of low fluorescence quantum yield of noble metal nanoclusters, non-negligible surface defects, and toxic half-quantum dots, and achieve shortened detection time, Low cost, good quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

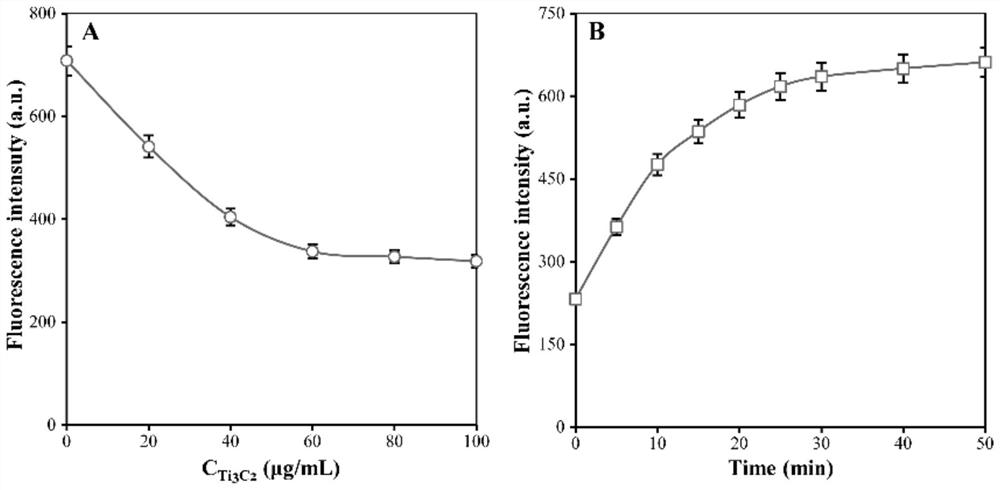

Method used

Image

Examples

Embodiment 1

[0044] The construction method of graphene quantum dot-MXene fluorescent sensor described in the present embodiment comprises the steps:

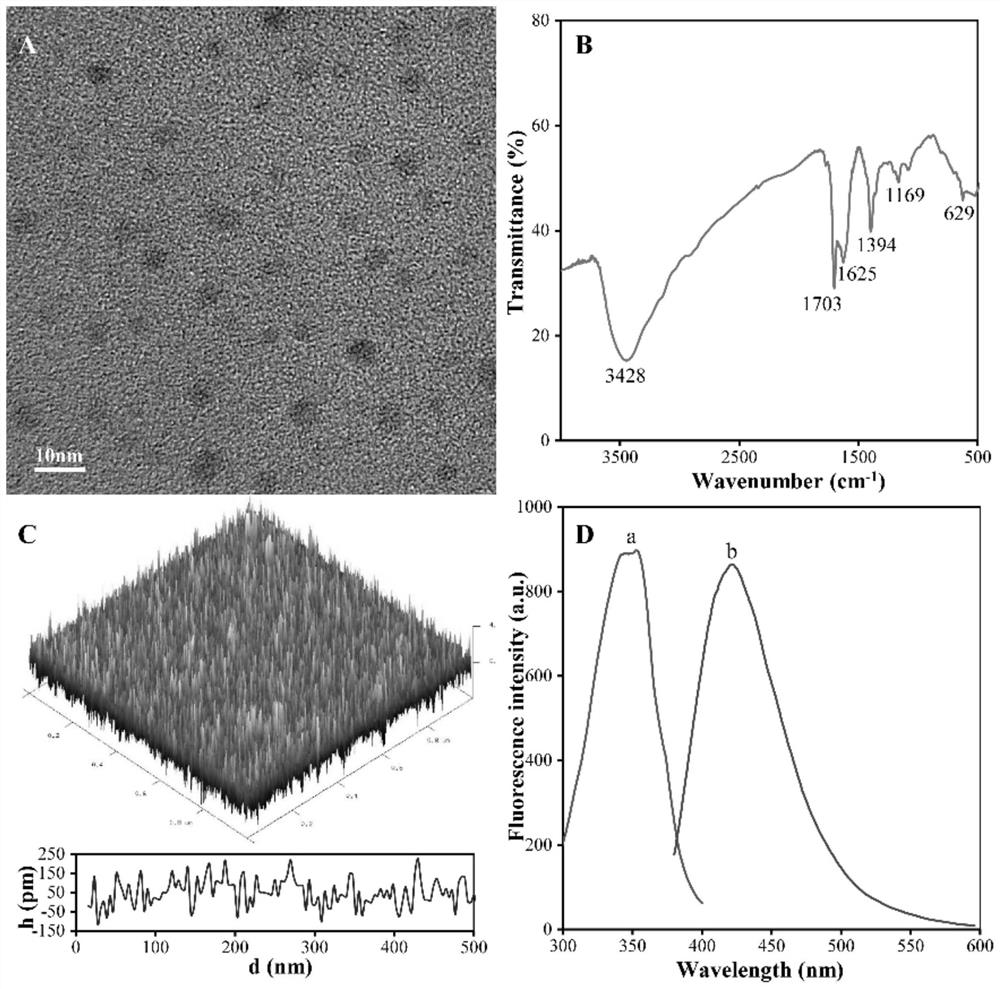

[0045] (1) Preparation of functionalized graphene quantum dots (Glu-His-GQD): citric acid (0.03mol), glutathione (0.01mol) and histidine (0.03mol) were mixed and dissolved in ultrapure water ( The mass ratio of the total amount of citric acid, glutathione and histidine to water was 1:1), and then evaporated at 80° C. for 2 h to remove all the water. Then, the mixture was heated at 180°C for 3 h to obtain Glu-His-GQD solid powder, which was dissolved in ultrapure water and neutralized to pH 7.0 with NaOH solution to form a transparent Glu-His-GQD solid powder. GQDs solution (20mg / ml). The solution was dialyzed in a dialysis bag with a molecular weight cut-off of 3 kDa, changing the water every 6 hours. Collect the solution in the bag, then vacuum dry at 60°C for 7 hours to obtain the Glu-His-GQD product;

[0046] (2) Preparation of aptame...

Embodiment 2

[0050] The construction method of graphene quantum dot-MXene fluorescent sensor described in the present embodiment comprises the steps:

[0051] (1) Preparation of functionalized graphene quantum dots (Glu-His-GQD): citric acid (0.01mol), glutathione (0.01mol) and histidine (0.01mol) were mixed and dissolved in ultrapure water ( The mass ratio of the total amount of citric acid, glutathione and histidine to water was 5:1), and then evaporated at 80° C. for 2 h to remove all the water. Then, the mixture was heated at 200°C for 2 h to obtain Glu-His-GQD solid powder, which was dissolved in ultrapure water and neutralized to pH 7.0 with NaOH solution to form a transparent Glu-His-GQD solid powder. GQDs solution (20mg / ml). The solution was dialyzed in a dialysis bag with a molecular weight cut-off of 3 kDa, changing the water every 6 hours. Collect the solution in the bag, then vacuum dry at 80°C for 3 hours to obtain the Glu-His-GQD product;

[0052] (2) Preparation of aptame...

Embodiment 3

[0056] The construction method of graphene quantum dot-MXene fluorescent sensor described in the present embodiment comprises the steps:

[0057] (1) Preparation of functionalized graphene quantum dots (Glu-His-GQD): citric acid (0.05mol), glutathione (0.01mol) and histidine (0.01mol) were mixed and dissolved in ultrapure water ( The mass ratio of the total amount of citric acid, glutathione and histidine to water was 3:1), and then evaporated at 80° C. for 2 h to remove all the water. Then, the mixture was heated at 160°C for 5 h to obtain Glu-His-GQD solid powder, which was dissolved in ultrapure water and neutralized to pH 7.0 with NaOH solution to form a transparent Glu-His- GQDs solution (20mg / ml). The solution was dialyzed in a dialysis bag with a molecular weight cut-off of 3 kDa, changing the water every 6 hours. Collect the solution in the bag, and then vacuum-dry it at 75°C for 4 hours to obtain the Glu-His-GQD product;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com