Silicon-oxygen composite negative electrode material, preparation method thereof and lithium ion battery

A negative electrode material and silicon-oxygen technology, which is applied in the field of silicon-oxygen composite negative electrode material and its preparation, can solve the problems of affecting the quality of the pole piece, the loss of active silicon, and the reduction of battery capacity, so as to improve the depth of lithium intercalation, reduce internal resistance, prevent the effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

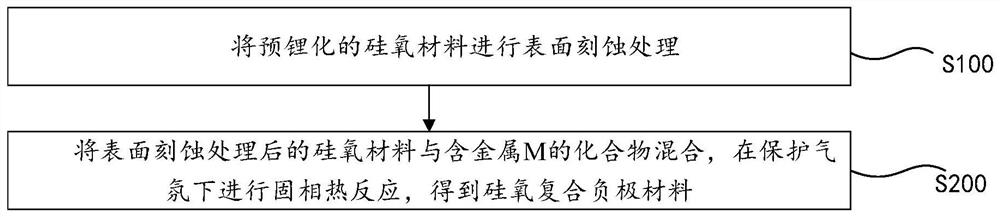

[0083] Second aspect, such as figure 1 As shown, the application provides a method for preparing a silicon-oxygen composite negative electrode material, comprising the following steps:

[0084] S100, performing surface etching treatment on the pre-lithiated silicon oxide material;

[0085] S200, mixing the silicon-oxygen material after the surface etching treatment with a compound containing metal M, and performing a solid-phase thermal reaction under a protective atmosphere to obtain a silicon-oxygen composite negative electrode material;

[0086] The silicon-oxygen composite negative electrode material includes an active material, and the active material includes a skeleton structure that runs through the active material and a silicon-oxygen material distributed on the skeleton structure; the skeleton structure includes silicon that is located inside the active material. A lithium acid skeleton and a water-insoluble silicate skeleton located on the surface of the active mat...

Embodiment 1

[0134] (1) react carbon-coated silicon-oxygen material SiO / C with metal lithium to obtain pre-lithiated carbon-coated silicon-oxygen material Li-SiO / C, wherein the lithium content is 10wt%;

[0135] (2) Soak the pre-lithiated material in 10wt% citric acid solution for 1 hour, etch the surface, then filter it with suction, and dry it in a dry environment at 80°C for 24 hours;

[0136] (3) Add magnesia (5g) and surface-etched pre-lithium silicon oxide (100g) into a ball mill, and after ball milling for 12 hours, transfer to a graphite crucible, treat at 850°C for 10 hours under a protective atmosphere, and then crush Sieve and classify to obtain the silicon-oxygen composite negative electrode material.

[0137] The silicon-oxygen composite negative electrode material prepared in this embodiment includes an active material and a carbon layer formed on the surface of the active material. The active material includes a skeleton structure and a silicon-oxygen material embedded in th...

Embodiment 2

[0140] (1) react carbon-coated silicon-oxygen material SiO / C with metal lithium to obtain pre-lithiated carbon-coated silicon-oxygen material Li-SiO / C, wherein the lithium content is 10wt%;

[0141] (2) Soak the pre-lithiated material in 10wt% citric acid solution for 1 hour, etch the surface, then filter it with suction, and dry it in a dry environment at 80°C for 24 hours;

[0142] (3) Add magnesia (2.5g), lithium carbonate (4.6g) and pre-lithium silicon oxide (100g) after surface etching into the ball mill together. After ball milling for 12 hours, transfer them to graphite crucible. After being treated at 850°C for 10 hours, it was crushed, sieved and classified to obtain a silicon-oxygen composite negative electrode material.

[0143] The silicon-oxygen composite negative electrode material prepared in this embodiment includes an active material and a carbon layer formed on the surface of the active material. The active material includes a skeleton structure and a silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com