Graphene-coated lithium ion battery and preparation method thereof

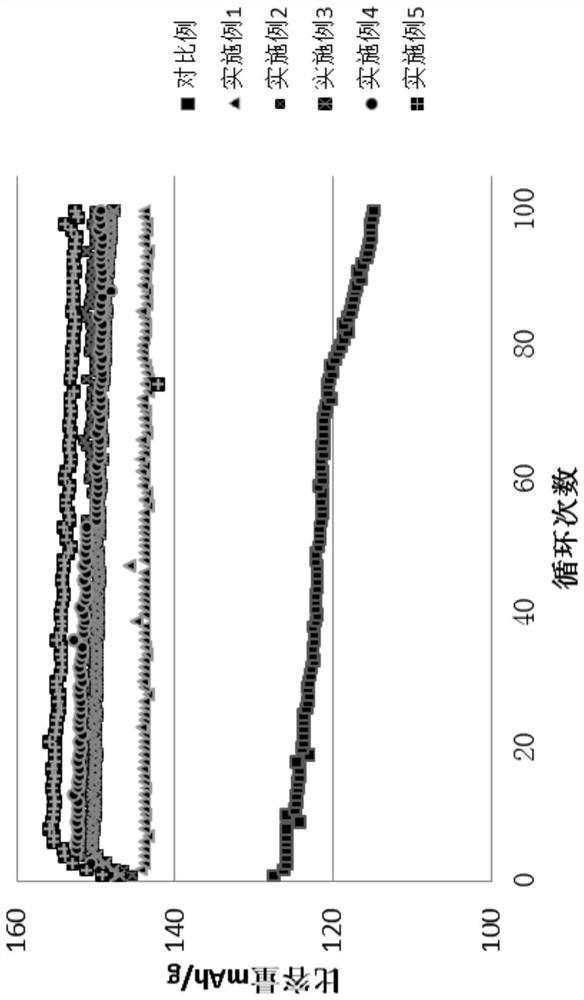

A lithium ion battery, graphene coating technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve difficult battery system coordination, low lithium ion conductivity and electronic conductivity, and material specific capacity Less than the theoretical specific capacity polarization phenomenon and other problems, to achieve the effect of improving ionic conductivity, stable cycle performance, and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment discloses a preparation method of a graphene-coated lithium ion battery, comprising the following steps:

[0044] S1. Preparation of LiFeO 4 / Graphene modified composite materials;

[0045] LiFeO in S1 4 The preparation method of / graphene modified composite material comprises the following steps:

[0046] S11, the LiOH·H 2 O was dissolved in deionized water under magnetic stirring; completely dissolved;

[0047] S12, under the condition of stirring, add H dropwise to the mixed solution obtained in S11 3 PO 4 , until a white suspension is added to the solution;

[0048] S13, dispersing the ethylenediamine-modified graphene oxide in deionized water, mixing and dispersing evenly;

[0049] S14, the FeSO 4 ·7H 2 O is dissolved in the mixed solution obtained in step S13, and mixed uniformly;

[0050]S15, adding the mixed solution obtained in S14 to the mixed solution obtained in S12, stirring evenly and continuing to stir for a certain period of tim...

Embodiment 2

[0067] The main difference between this embodiment and embodiment 1 is:

[0068] Before S11 is carried out, graphene oxide is grafted with polystyrene through esterification reaction, and the specific dosage is shown in Table 1;

[0069] In the S17, after vacuum drying and high-temperature calcination, the precipitated substance is removed from polystyrene to obtain LiFeO with porous channels. 4 / Graphene modified composite materials.

[0070] The process condition of preferred high temperature calcination is:

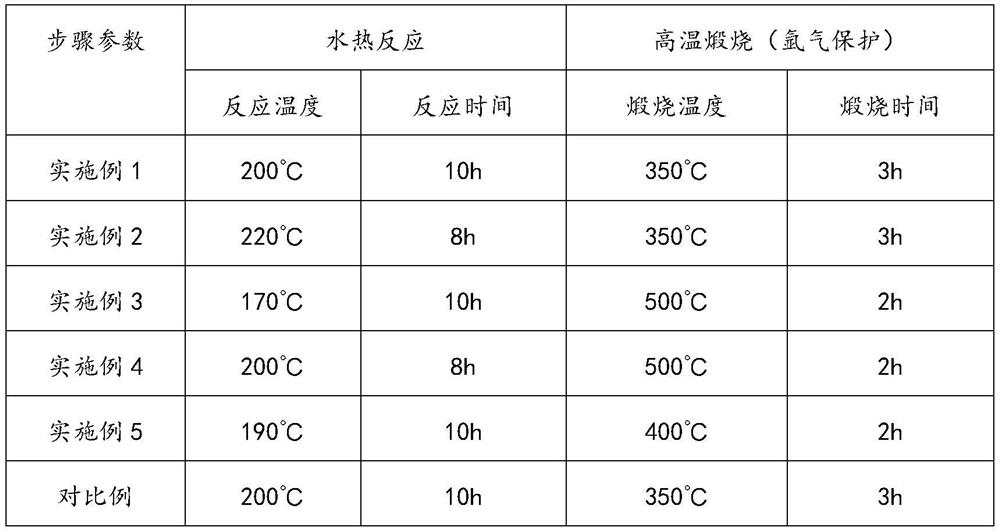

[0071] Calcination temperature: 350°C to 500°C; Argon protection. The specific high-temperature calcination process conditions are shown in Table 2.

Embodiment 3

[0073] The main difference between this embodiment and embodiment 1 is:

[0074] Before S11 is carried out, graphene oxide is grafted with polystyrene through esterification reaction, and the specific dosage is shown in Table 1;

[0075] In the S17, after vacuum drying and high-temperature calcination, the precipitated substance is removed from polystyrene to obtain LiFeO with porous channels. 4 / Graphene modified composite materials.

[0076] The specific high-temperature calcination process conditions are shown in Table 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap