Low-walled carbon nanotube fiber bundle and preparation process thereof

A technology of carbon nanotube fiber and double-walled carbon nanotube, which is applied in the field of oligowalled carbon nanotube fiber bundle and its preparation technology, can solve problems such as the purity of carbon nanotube fiber, and achieve sufficient and stable energy and material exchange High and uniform reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

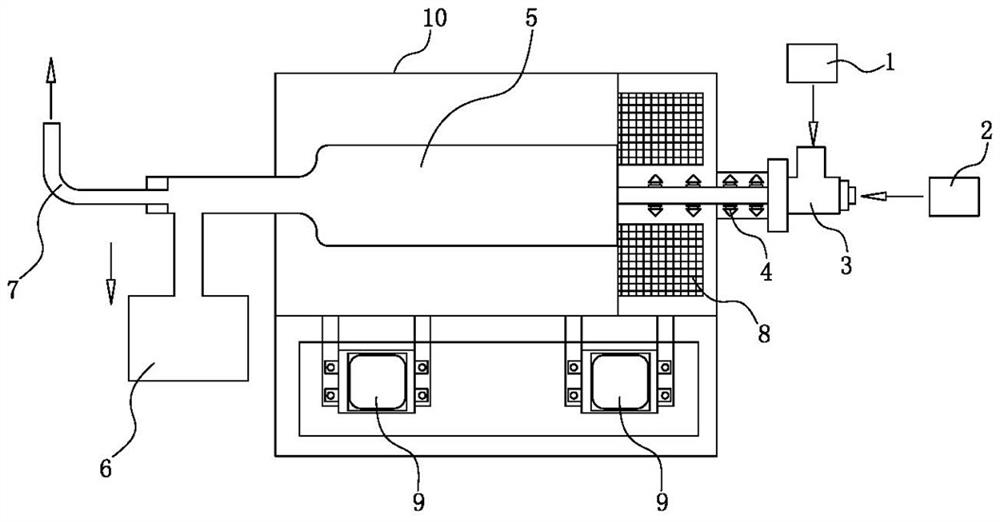

[0055] Refer to attached figure 1 , a horizontal microwave plasma cloud device, including a mixed feed member 3, an ignition device 4, a quartz inner liner 5, a receiving device 6 and an exhaust gas discharge device 7, wherein the mixed feed member 3, the ignition device 4, the quartz inner The liner 5 and the receiving device 6 are arranged sequentially according to the preparation process of feeding, ignition and heating, reaction and receiving, and the mixed feeding member 3 is connected with a micro injection pump and a carrier gas inlet device 2, and the mixed slurry passes through the micro The syringe pump is injected into the mixed feed member 3, and the mixed carrier gas enters into the mixed feed member 3 through the carrier gas inlet device 2; and the quartz liner 5 is connected with a microwave power supply 8 and a magnetron 9, and the magnetron The tube 9 controls the stable output and operation of the microwave power, and the outer wall of the quartz-lined tube 5...

Embodiment 2

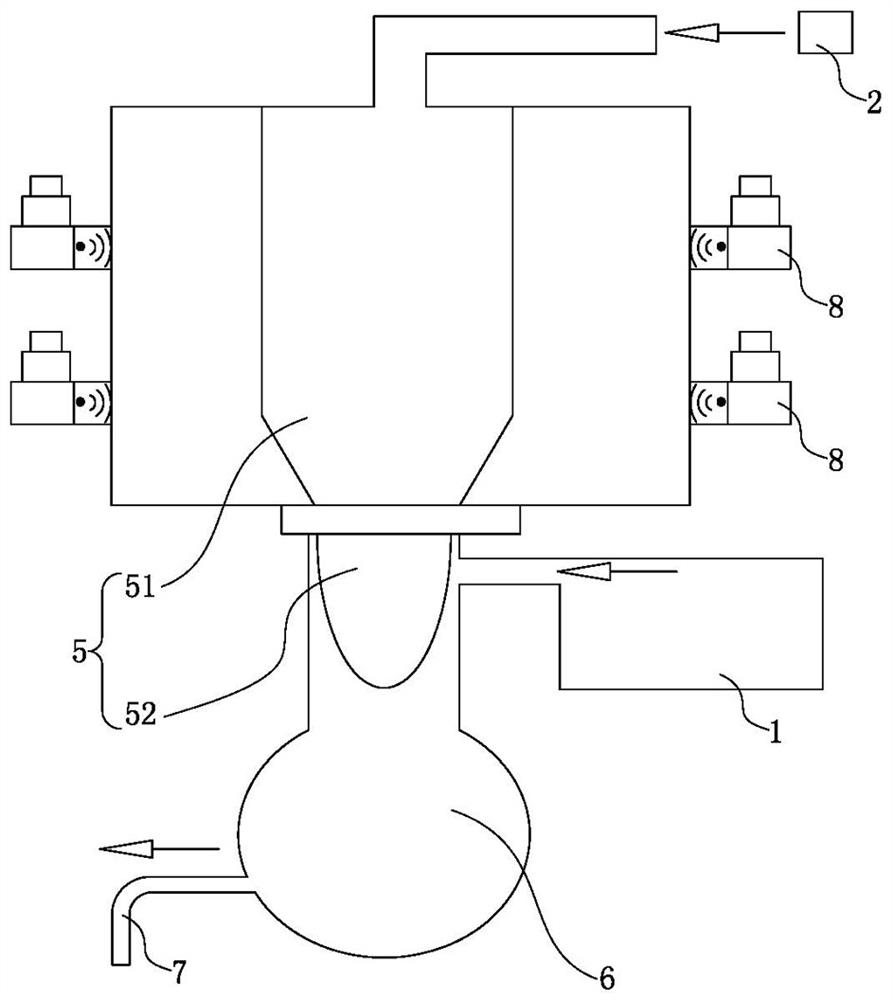

[0057] Refer to attached figure 2 , a vertical microwave plasma cloud equipment, according to the preparation process of carrier gas feed, temperature rise, reaction, and material collection, including carrier gas inlet device 2, quartz inner liner 5, material receiving device 6 and tail gas discharge device arranged in sequence 7, wherein the quartz liner 5 includes a plasma cloud reaction zone 51 and a mixing reaction zone 52, the output end of the plasma cloud reaction zone 51 is connected to the input end of the mixing reaction zone 52, the plasma cloud reaction zone 51 is connected with a microwave power supply 8, and the mixing The reaction zone 52 is connected with a micro-injection pump, and the outer wall of the quartz liner 5 corresponding to the plasma cloud reaction zone 51 is provided with a stainless steel water-cooled clip 10; after the mixed carrier gas enters the plasma cloud reaction zone 51, it is heated up under the action of the plasma cloud, and then The...

Embodiment 3

[0059] Preparation of organic slurry: adding ferrocene to ethanol, stirring evenly, wherein the mass content of ferrocene is 5%;

[0060] Preparation of mixed slurry: adding methyl mercaptan as a co-catalyst into the organic slurry and mixing evenly to prepare mixed slurry.

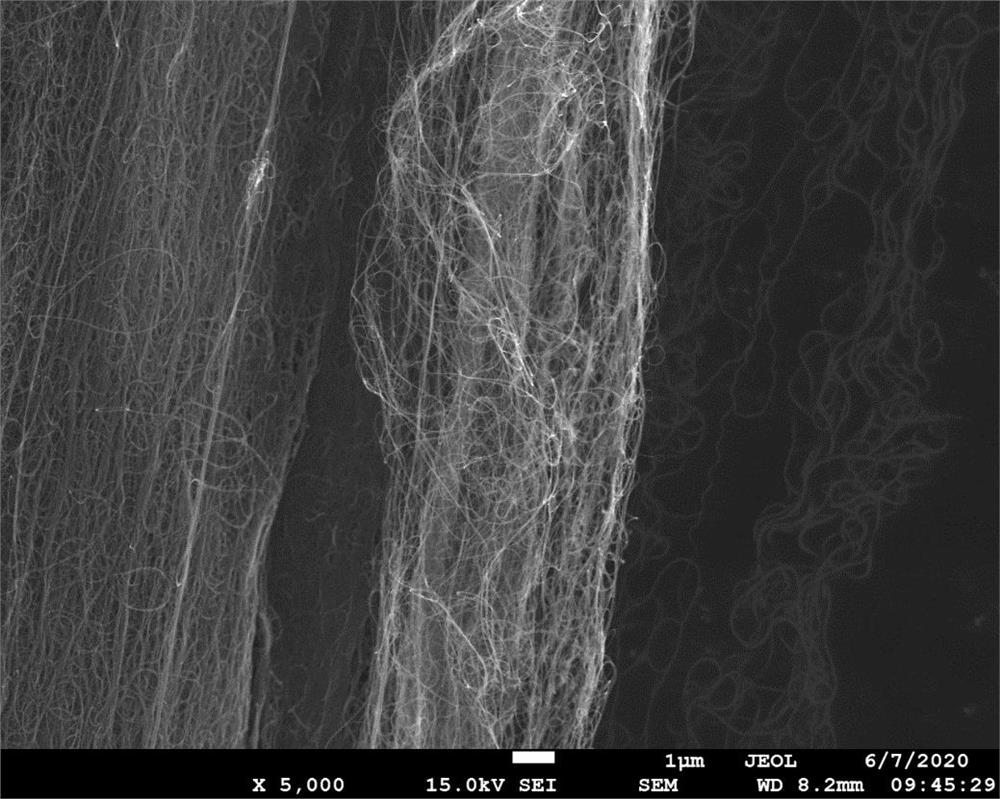

[0061] This embodiment adopts the vertical microwave plasma cloud equipment of Embodiment 2, the microwave power of the control equipment is 3KW, and Ar / H is fed through the carrier gas inlet device 2 2 Mix the carrier gas, and control the flow rate of Ar in the mixed carrier gas to be 50L / min, H 2 The flow rate is 20L / min, Ar / H 2 The mixed carrier gas is excited by microwaves in the plasma cloud reaction zone 51 of the quartz liner 5 to generate a high-temperature ion cloud flame, and the temperature of the mixed reaction zone 52 is rapidly raised to 1080°C; then the mixed slurry prepared above is injected into the In the mixed reaction zone 52 of the quartz liner 5, the injection speed of the micro-in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com