Ultra-stable Y-type molecular sieve as well as preparation method and application thereof

A technology of molecular sieve and B acid, applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of poor activity and selectivity of low-temperature liquid-phase transalkylation catalysts, improve the diffusion of reactants, and reduce side reactions , The effect of high proportion of B acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Take 1.2g HF and add it to 150g 0.2mol / L ammonium fluorosilicate solution, after stirring evenly, add 30g SiO 2 / Al 2 o 3 It is a Y-type molecular sieve of 5.8, and the temperature is raised to 60° C. and stirred for 30 minutes, and then filtered, washed and dried to obtain a pretreated Y molecular sieve.

[0073] Get 20g of pretreated molecular sieves and disperse them in 200g of ammonium chloride aqueous solution with a concentration of 9% by weight (calculated as ammonium chloride) for beating and stirring. After 20 minutes, add 1mol / L oxalic acid solution for acid treatment. The acid treatment temperature is 90°C. The time is 1h; finally wash with 20 times deionized water and dry at 120°C for 12h;

[0074] Then put it into a hydrothermal furnace and raise the temperature to 650°C. During the hydrothermal ultra-stabilization treatment process, the uniform heating rate is 8°C / min, and 100% by volume of steam is passed through for roasting for 2 hours, and dried at 1...

Embodiment 2

[0078] Take 0.7g NH 4 F was added to 190g of 0.2mol / L ammonium fluorosilicate solution, after stirring evenly, 36g of SiO 2 / Al 2 o 3 For 5.4 Y-type molecular sieves, heat up to 80°C and stir for 15 minutes, then filter, wash and dry to obtain pretreated Y molecular sieves.

[0079] Take 25g of pretreated molecular sieves and disperse them in 220g of ammonium sulfate aqueous solution with a concentration of 9% by weight (calculated as ammonium chloride) for beating and stirring. After 20 minutes, add 0.6mol / L acetic acid solution for acid treatment. The acid treatment temperature is 75°C. The time is 1.5h; finally wash with 20 times of deionized water and dry at 120°C for 12h; then put it into a hydrothermal furnace and raise the temperature to 670°C. , passed through 80 volume % steam for 2 h, and dried at 120° C. for 12 h to prepare a USY type molecular sieve, marked as sample USY-B.

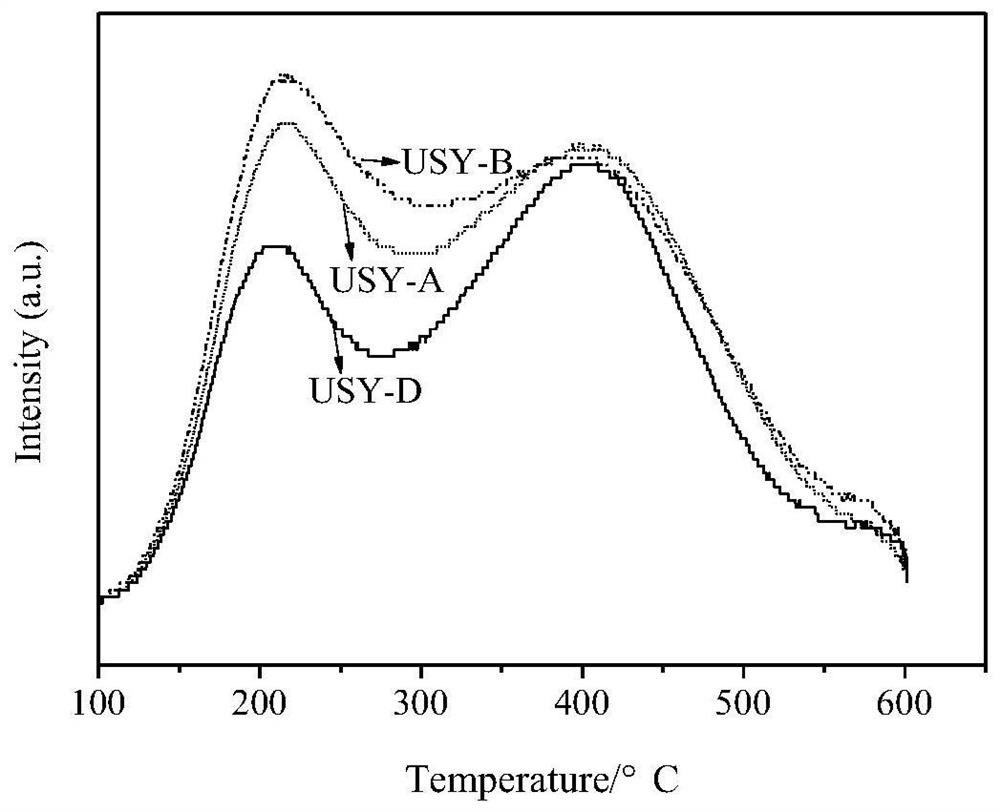

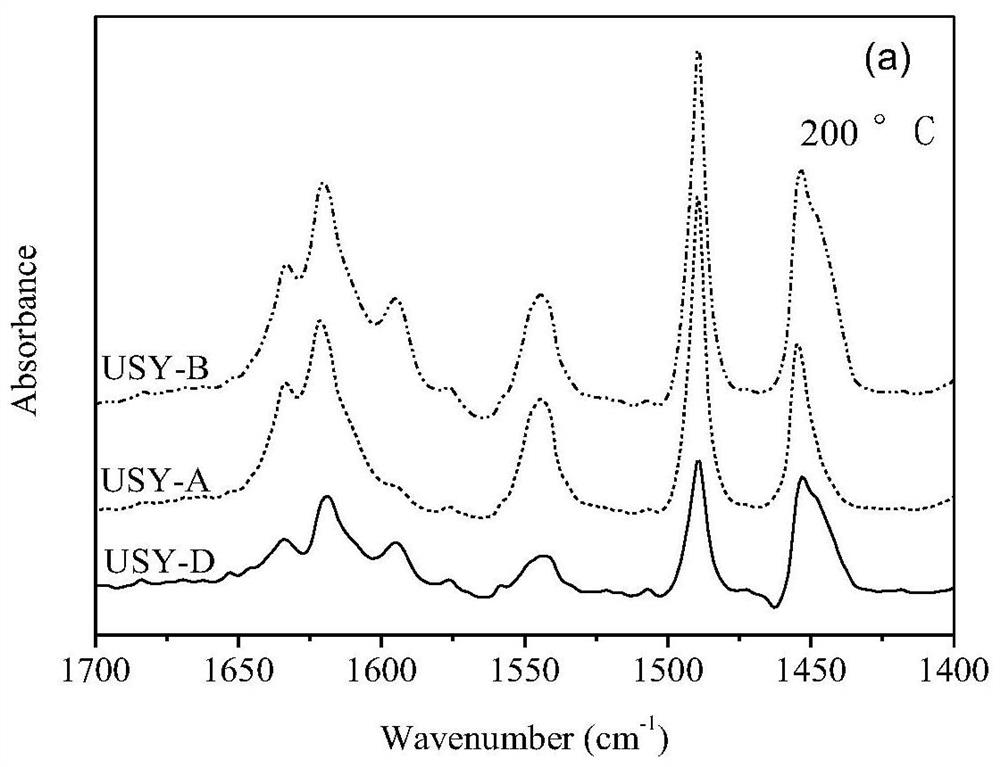

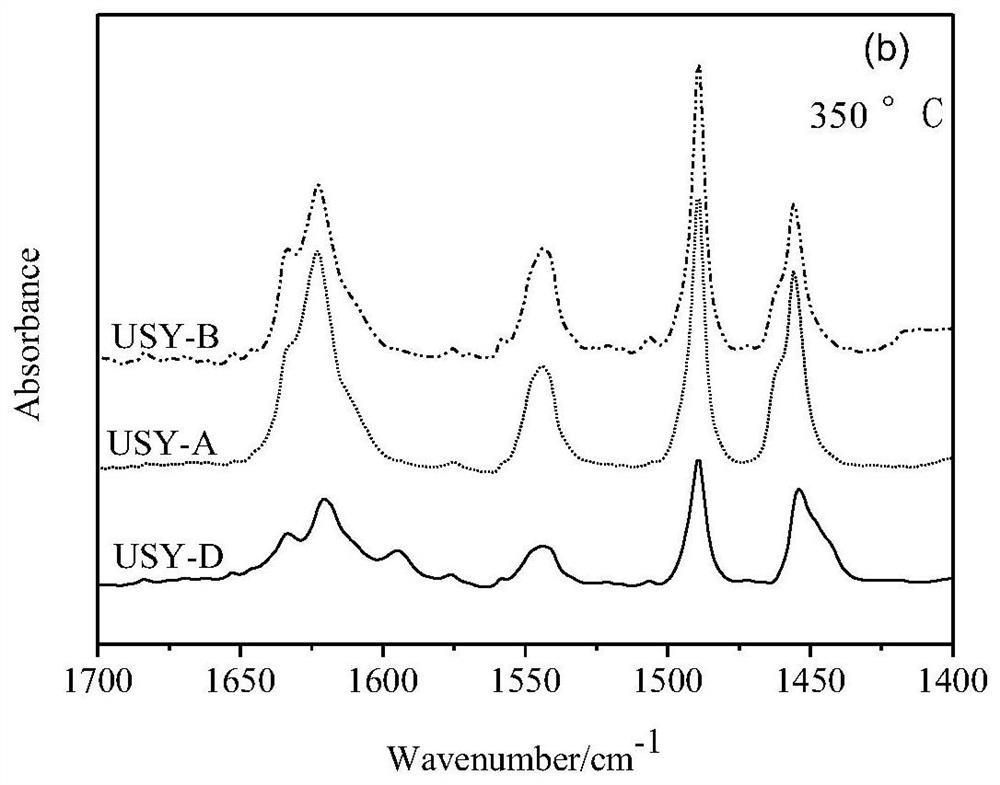

[0080] NH on USY-B 3 - Characterization of TPD, Py-IR and XRD, the results of which a...

Embodiment 3

[0083] Take 1.0g HF and add it to 165g 0.2mol / L ammonium fluorosilicate solution, after stirring evenly, add 40g SiO 2 / Al 2 o 3 For 6.5 Y-type molecular sieves, heat up to 50°C and stir for 1 hour, then filter, wash and dry to obtain pretreated Y molecular sieves.

[0084] Take 30g of pretreated molecular sieves and disperse them in 280g of ammonium nitrate aqueous solution with a concentration of 10% by weight (calculated as ammonium chloride) for beating and stirring. After 20 minutes, add 1.4mol / L oxalic acid solution for acid treatment. The acid treatment temperature is 90°C. The time is 2 hours; finally wash with 20 times of deionized water and dry at 120°C for 12 hours; then put it into a hydrothermal furnace and raise the temperature to 630°C. Roasting with 100% by volume steam for 2 hours, and drying at 120° C. for 12 hours to prepare a USY type molecular sieve, marked as sample USY-C.

[0085] USY-C for NH 3 - Characterization of TPD, Py-IR and XRD with results s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com