Ultra-long one-dimensional dihalogen tungsten dioxide material and preparation method thereof

A technology of tungsten dioxide and tungsten halide, applied in chemical instruments and methods, inorganic chemistry, tungsten compounds, etc., can solve problems such as high temperature and small long diameter, and achieve the effect of stable supply and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

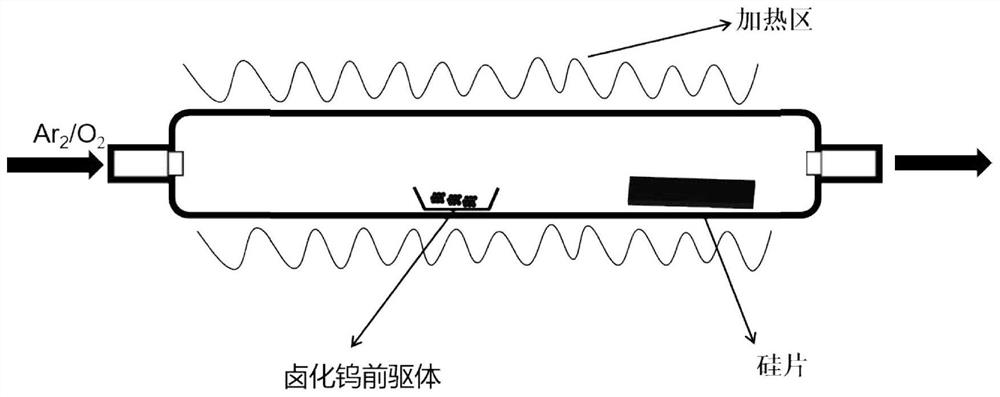

[0023](1) Cut a silicon wafer with a size of 1cm×1cm with a silicon wafer knife, ultrasonically clean it with acetone, ethanol, and deionized water for 5 minutes and dry it with an argon stream, and place it at a suitable position downstream of the tube furnace; weigh it in a glove box. Take 20mg of WCl 6 The powder is placed in the middle of the tube furnace tube; connect all parts of the CVD system to ensure good airtightness. Such as figure 1 Shown is a schematic diagram of the chemical vapor deposition device used in the experiment

[0024] (2) Turn on the vacuum pump to evacuate the system to vacuum; mix argon and air in the gas mixing system at a ratio of 2:3, and then pass it into the vacuum system with a total flow rate of 50 sccm; adjust the valve of the vacuum pump to make the system pressure It reaches 550Pa and remains stable.

[0025] (3) Start the tube furnace and heat it to 300°C at a heating rate of 10°C / s and keep it warm for 30 minutes. After the reaction ...

Embodiment 2

[0029] (1) Cut a silicon wafer with a size of 1cm×1cm with a silicon wafer knife, ultrasonically clean it with acetone, ethanol, and deionized water for 5 minutes and dry it with an argon stream, and place it at a suitable position downstream of the tube furnace; weigh it in a glove box. Take 50mg of WCl 6 The powder is placed in the middle of the tube furnace tube; connect all parts of the CVD system to ensure good airtightness. Such as figure 1 Shown is a schematic diagram of the chemical vapor deposition device used in the experiment

[0030] (2) Turn on the vacuum pump to evacuate the system to vacuum; mix argon and air at a ratio of 2:3 in the gas mixing system, and then pass it into the vacuum system with a total flow rate of 300 sccm; adjust the valve of the vacuum pump to make the system pressure It reaches 550Pa and remains stable.

[0031] (3) Start the tube furnace and heat it to 300°C at a heating rate of 10°C / s and keep it warm for 30 minutes. After the reactio...

Embodiment 3

[0033] (1) Cut a silicon wafer with a size of 1cm×1cm with a silicon wafer knife, ultrasonically clean it with acetone, ethanol, and deionized water for 5 minutes and dry it with an argon stream, and place it at a suitable position downstream of the tube furnace; weigh it in a glove box. Take 20mg of WCl 6 The powder is placed in the middle of the tube furnace tube; connect all parts of the CVD system to ensure good airtightness. Such as figure 1 Shown is a schematic diagram of the chemical vapor deposition device used in the experiment

[0034] (2) Turn on the vacuum pump and evacuate the system to a vacuum; Compressed air is passed into the vacuum system with a total flow of 50 sccm; the valve of the vacuum pump is adjusted to make the system pressure reach 10 5 Pa and remain stable.

[0035] (3) Start the tube furnace to heat up to 500°C at a heating rate of 10°C / s and keep it warm for 30 minutes. After the reaction is over, turn off the electric furnace, vacuum pump and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com