Synthesis method of tetraethylene silane

A technology of tetraethylene silane and synthesis method, which is applied in the direction of silicon organic compounds, chemical instruments and methods, compounds of group 4/14 elements of the periodic table, etc., and can solve incomplete substitution, low yield and purity, and difficulty in carrying out, etc. problem, to achieve the effect of less reaction steps, simple operation and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

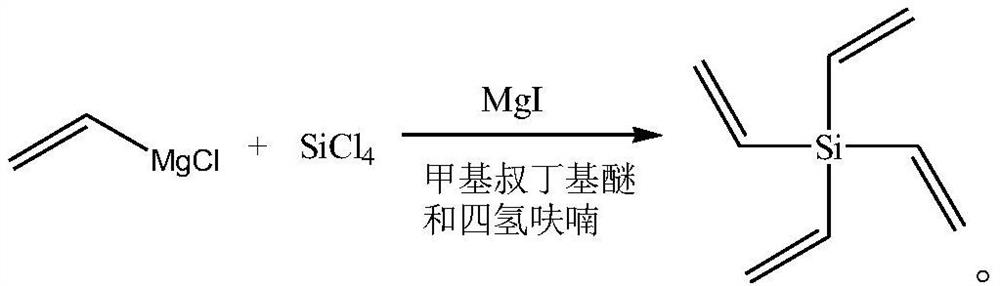

Method used

Image

Examples

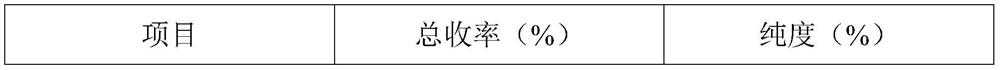

Embodiment 1

[0021] The synthetic method of tetraethylene silane, its synthetic steps are as follows:

[0022] 1) Preparation of vinylmagnesium chloride solution

[0023] Under the protection of nitrogen, take 9.724g (0.4mol) of magnesium chips and add them to 145.86mL of tetrahydrofuran, stir and heat to 65°C, pass in excess vinyl chloride gas, and keep stirring at 65°C to react until the magnesium chips completely disappear to obtain ethylene base magnesium chloride solution.

[0024] 2) Preparation of Tetraethylenesilane

[0025] Dissolve 16.7g (0.1mol) of tetrachlorosilane in 130mL of methyl tert-butyl ether, add 0.1g of catalyst magnesium iodide, control the temperature of the resulting system at 20°C, and slowly add All the above-mentioned vinylmagnesium chloride solutions (dropping time is 2h), after the dropwise addition, maintain 20°C and continue to stir for 2h for Grignard reaction, then slowly add 75mL of water dropwise to quench the reaction, and directly separate the phases...

Embodiment 2

[0028] The synthetic method of tetraethylene silane, its synthetic steps are as follows:

[0029] 1) Preparation of vinylmagnesium chloride solution

[0030] Under the protection of nitrogen, take 9.724g (0.4mol) of magnesium chips and add them to 155.58mL of tetrahydrofuran, stir and heat to 68°C, pass in excess vinyl chloride gas, and keep stirring at 68°C to react until the magnesium chips completely disappear to obtain ethylene base magnesium chloride solution.

[0031] 2) Preparation of Tetraethylenesilane

[0032] Dissolve 16.7g (0.1mol) of tetrachlorosilane in 133.6mL of methyl tert-butyl ether, add 0.05g of catalyst magnesium iodide, control the temperature of the resulting system at 24°C, and slowly drop Add all the above-mentioned vinylmagnesium chloride solutions (dropping time is 2.5h). After the dropwise addition, keep stirring at 24°C for 3h for Grignard reaction, and then slowly add 80mL of water dropwise to quench the reaction. After the reaction is completed...

Embodiment 3

[0034] The synthetic method of tetraethylene silane, its synthetic steps are as follows:

[0035] 1) Preparation of vinylmagnesium chloride solution

[0036] Under the protection of nitrogen, take 10.21g (0.42mol) of magnesium chips and add them to 158.26mL of tetrahydrofuran, stir and heat to 70°C, pass in excess vinyl chloride gas, and keep stirring at 70°C to react until the magnesium chips completely disappear to obtain ethylene base magnesium chloride solution.

[0037] 2) Preparation of Tetraethylenesilane

[0038] Dissolve 16.7g (0.1mol) of tetrachlorosilane in 116.9mL of methyl tert-butyl ether, add 0.08g of catalyst magnesium iodide, control the temperature of the resulting system at 25°C, and slowly drop Add all the above-mentioned vinylmagnesium chloride solutions (dropping time is 2.3h). After the dropwise addition, maintain 25°C and continue stirring for 2.5h for Grignard reaction, then slowly add 78mL of water dropwise to quench the reaction. After the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com