Preparation method and production device of resin adhesive

A technology for resin adhesives and production equipment, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc. Performance, affecting practicability and market acceptance, etc., to achieve the effect of avoiding material adhesion and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

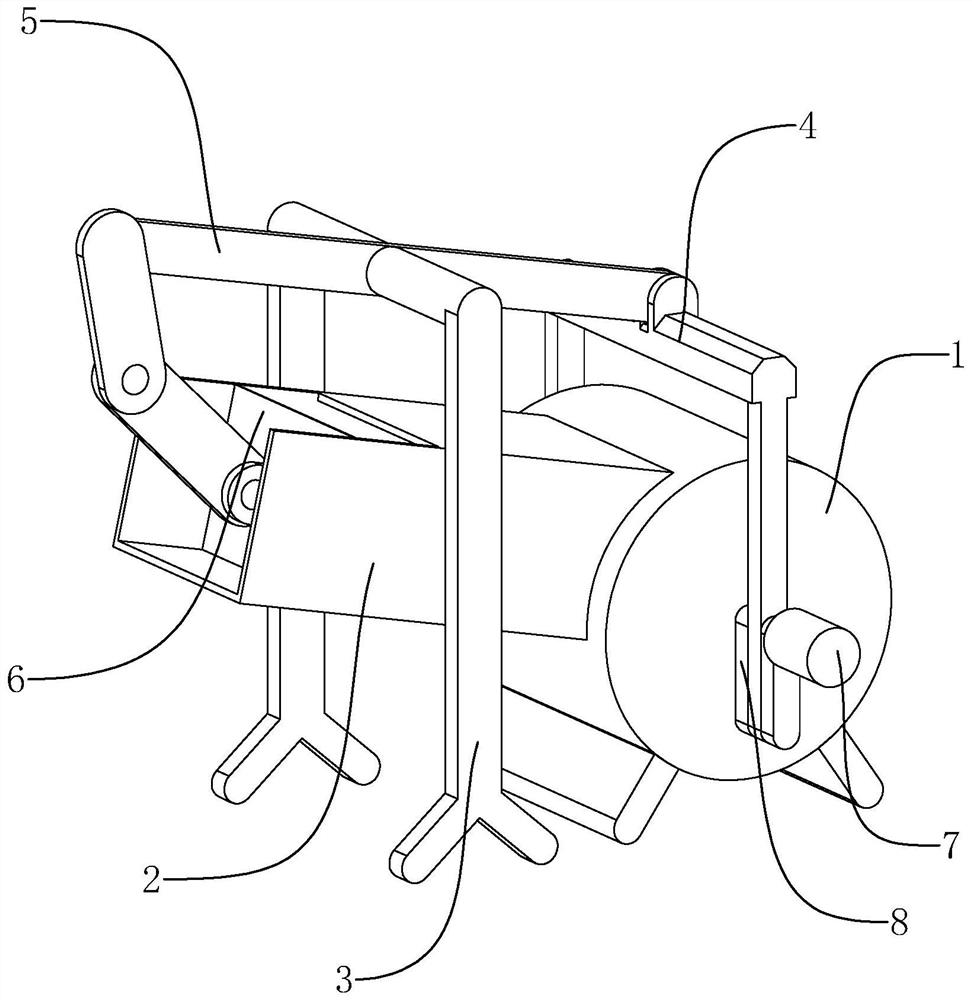

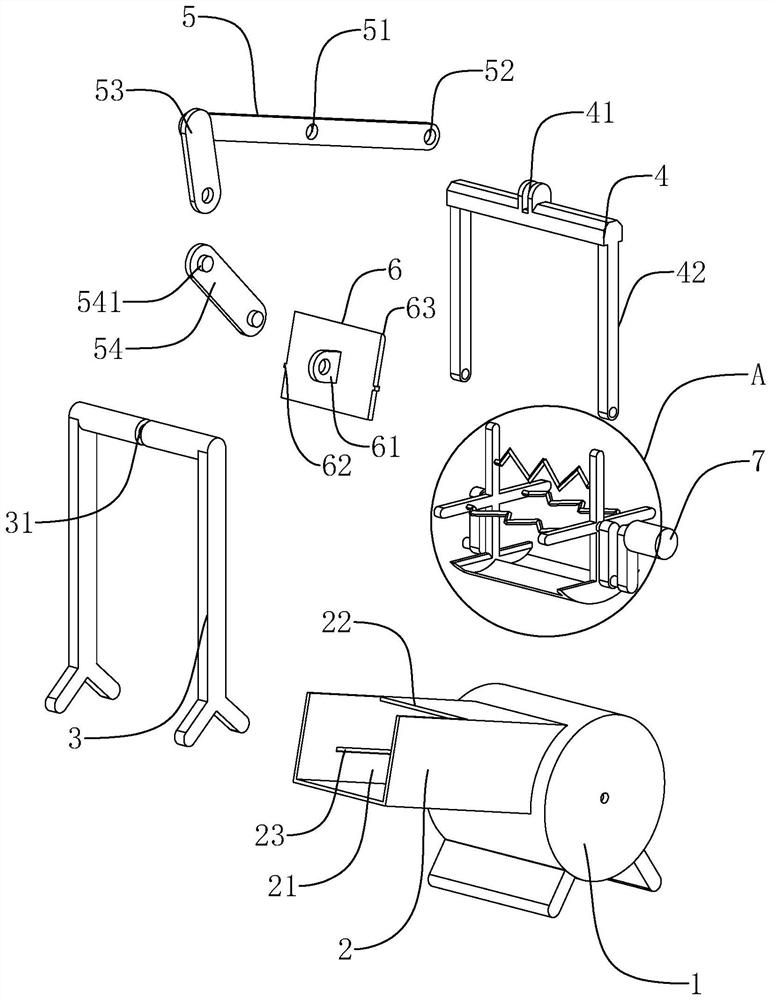

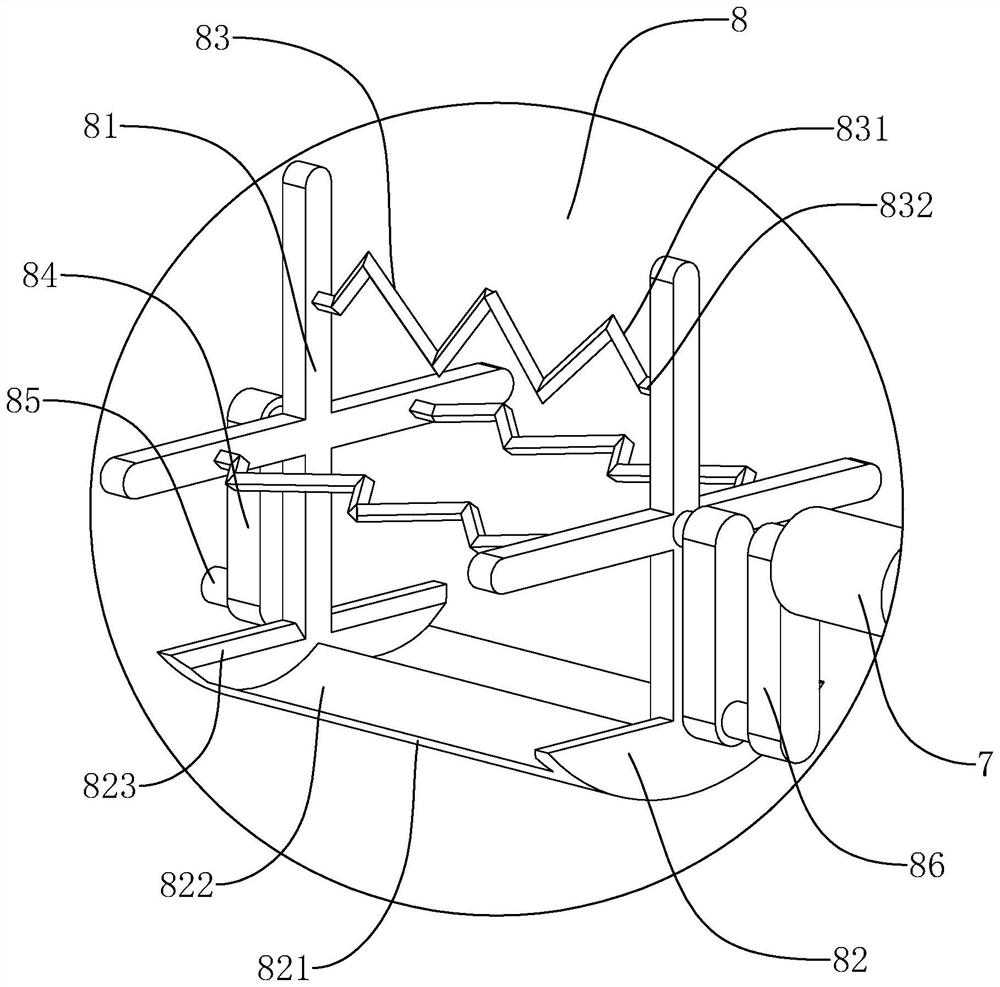

Image

Examples

preparation example Construction

[0035] A method for preparing a resin adhesive, comprising the steps of:

[0036] (1), import diethoxy bisphenol A dipropylene ester into the processing mixer and stir for 10 minutes, and ultrasonically disperse the stirred diethoxy bisphenol A dipropylene ester for 40 minutes to obtain the mixed raw material;

[0037] (2), introduce hydrogenated bisphenol A epoxy resin, active diluent, cationic initiator, photoinitiator, filler, toughening agent and solvent into the mechanical stirrer, stir at high speed for 3-4h and naturally solidified to obtain a mixed slurry;

[0038] (3), the mixed slurry is vacuum-dried to obtain a photosensitive resin material;

[0039] Wherein: the weight ratio of the initial mixing material in the preparation of the mixed slurry, hydrogenated bisphenol A epoxy resin, reactive diluent, cationic initiator, photoinitiator, filler, toughening agent and solvent is 13.5-14.0 :28.5-29.0:49.3-51.3:0.3-0.6:0.3-0.6:0.5-1:2-3:0.3-0.6. And the reactive diluen...

Embodiment 1

[0048] A method for preparing a resin adhesive, comprising the steps of:

[0049] (1), import diethoxy bisphenol A dipropylene ester into the processing mixer and stir for 10 minutes, and ultrasonically disperse the stirred diethoxy bisphenol A dipropylene ester for 40 minutes to obtain the mixed raw material;

[0050] (2), hydrogenated bisphenol A epoxy resin, 3,4-epoxycyclohexylmethyl, 3-ethyl-3-oxetanemethanol, 1,4-cyclohexyldimethanol divinyl ether and Bornyl methacrylate, sulfonium triarylhexafluoroantimonate, 1-hydroxycyclohexyl phenyl ketone, silica, chloride-methyl methacrylate-butadiene-styrene copolymer, and propylene carbonate The ester and mixed raw materials are introduced into a mechanical stirrer, stirred at high speed for 3 hours and naturally solidified to obtain a mixed slurry;

[0051] (3), the mixed slurry is vacuum-dried to obtain a photosensitive resin material;

[0052] Wherein: the mixed primary material in the preparation of the mixed slurry, hydroge...

Embodiment 2

[0061] The difference between embodiment two and embodiment one is that the resin binder preparation method in embodiment two comprises the following steps:

[0062] (1), import diethoxy bisphenol A dipropylene ester into the processing mixer and stir for 10 minutes, and ultrasonically disperse the stirred diethoxy bisphenol A dipropylene ester for 40 minutes to obtain the mixed raw material;

[0063] (2), hydrogenated bisphenol A epoxy resin, 3,4-epoxycyclohexyl carboxylate, 3-ethyl-3-oxetanemethanol, 1,4-cyclohexyldimethanol divinyl ether As well as bornyl methacrylate, sulfonium triarylhexafluoroantimonate, 1-hydroxycyclohexyl phenyl ketone, silicon dioxide, chloride-methyl methacrylate-butadiene-styrene copolymer and carbonic acid Acrylic ester and mixed primary material are introduced into a mechanical stirrer, stirred at high speed for 3.5 hours and naturally solidified to obtain a mixed slurry;

[0064] (3), the mixed slurry is vacuum-dried to obtain a photosensitive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com