Preparation method of ultra-pure, ultra-thick and compact aluminum film

An ultra-thick, aluminum film technology, applied in the field of ultra-pure, ultra-thick, dense aluminum film preparation on the surface of metal workpieces to be plated, to achieve high purity, high film density, and good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

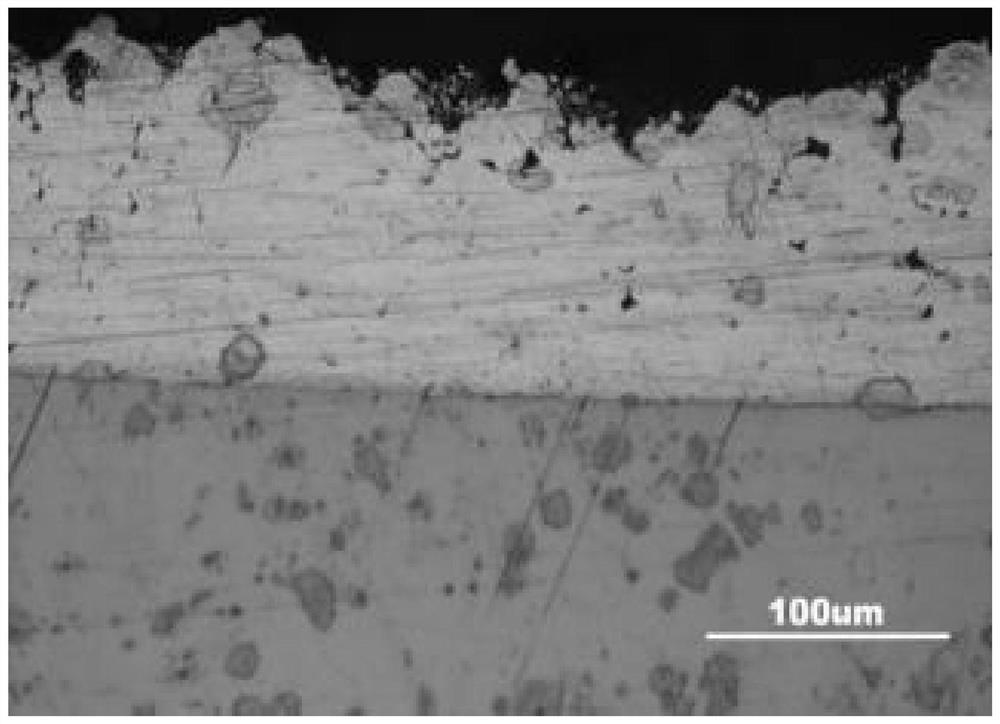

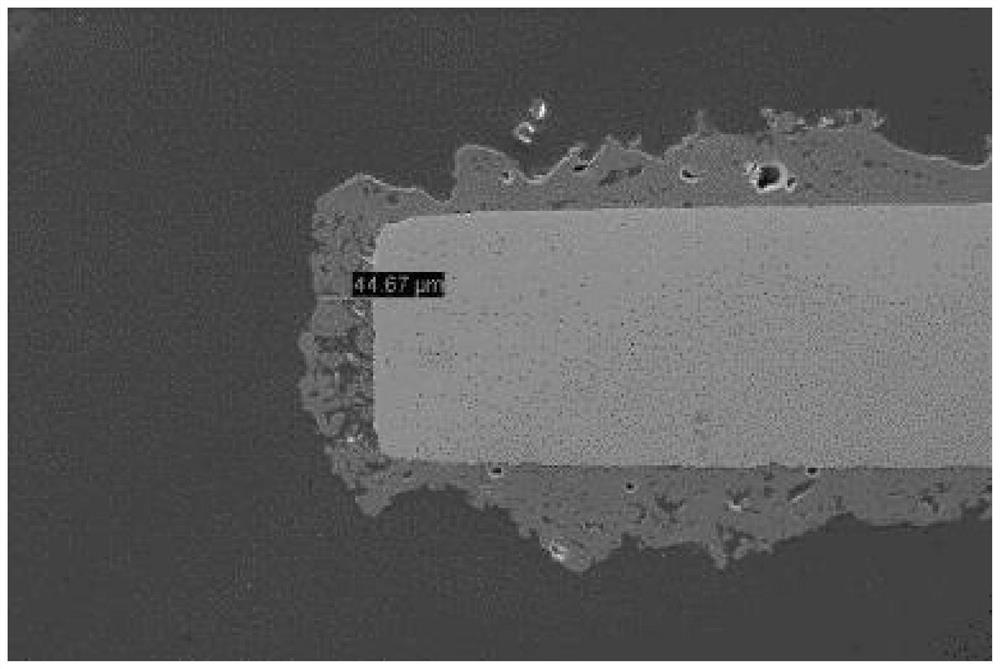

[0030] The preparation method of a kind of ultra-pure, ultra-thick, dense aluminum film that the present invention proposes, comprises the following steps: firstly after the workpiece to be plated is cleaned through the cleaning line, enters the vacuum chamber, and when the vacuum degree reaches 10 -2 -10 -4 After Pa, inert gas is introduced into the vacuum chamber to make the vacuum degree reach 10Pa-10 -1 Pa; turn on the pulse electrode installed in the vacuum chamber to stimulate the formation of plasma, and at the same time apply a negative DC bias to the workpiece to be plated, and use the plasma to perform in-situ sputtering cleaning on the surface of the workpiece to be plated; then turn on the magnetron sputtering power supply according to the demand, adjust the reduction The amount of inert gas charged, through the magnetron sputtering high-purity aluminum target, the sputtered aluminum atoms are excited and ionized in the plasma, and at the same time, because the wor...

Embodiment

[0042] The sheet-shaped nickel-based alloy material is used as an example for the workpiece to be plated.

[0043] 1. Install pure aluminum targets with a purity greater than 99.99% in the vacuum chamber;

[0044] 2. The workpiece to be plated is cleaned by an ultrasonic cleaning line, and thoroughly dried after dewaxing, degreasing and degreasing;

[0045] 3. Install the workpiece to be plated, the distance between the workpiece to be plated and the target is 60-140mm, and the optimal distance is 100mm;

[0046] 4. Vacuuming, the background vacuum is better than 3x10 -3 Pa;

[0047] 5. Argon filling 1-10 -1 Pa, turn on the pulse plasma generator, load the workpiece to be plated with a negative bias voltage, and perform sputter cleaning on the workpiece to be plated for 5-10 minutes, and the best time is 8 minutes;

[0048] 6. Adjust the amount of argon gas, apply a bias voltage of -100V to -200V to the workpiece to be plated, and turn on the magnetron sputtering power sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com