Nanofiber wrap yarn, preparation method of nanofiber wrap yarn, nanofiber wrap yarn plied yarn and application of nanofiber wrap yarn plied yarn

A technology of nanofiber and covered yarn, which is applied in the fields of nanofiber covered yarn and its preparation, nanofiber covered yarn strand and its application, and can solve the problems of easy oxidation of silver, high cost, and affecting the appearance of fabrics, etc., and achieve Low cost, reduced consumption, and excellent electric heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

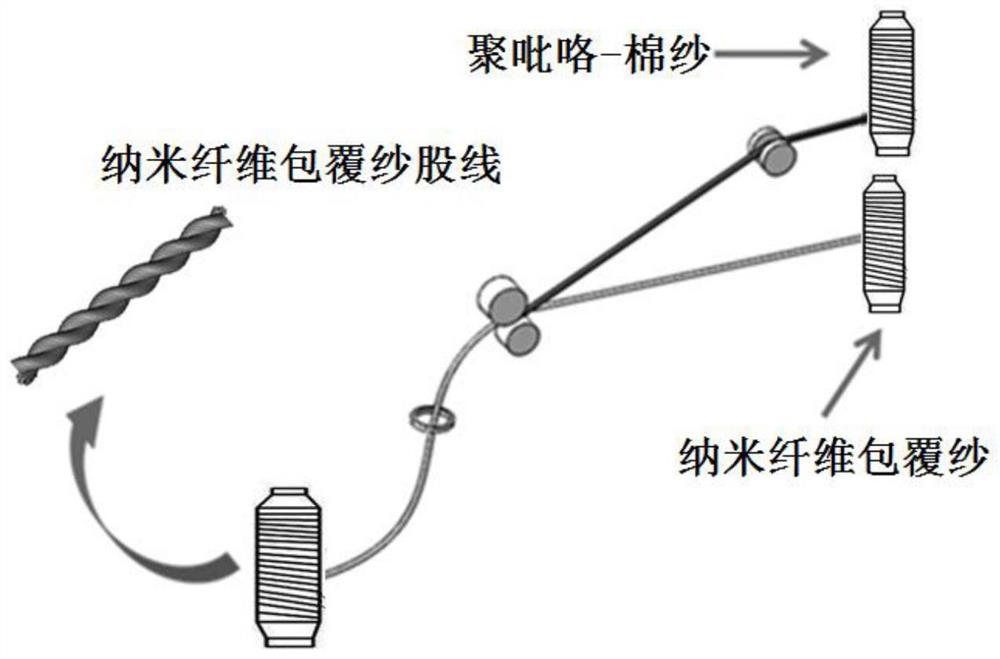

[0039] The present invention also provides a preparation method of the nanofiber covered yarn described in the above technical solution, comprising the following steps:

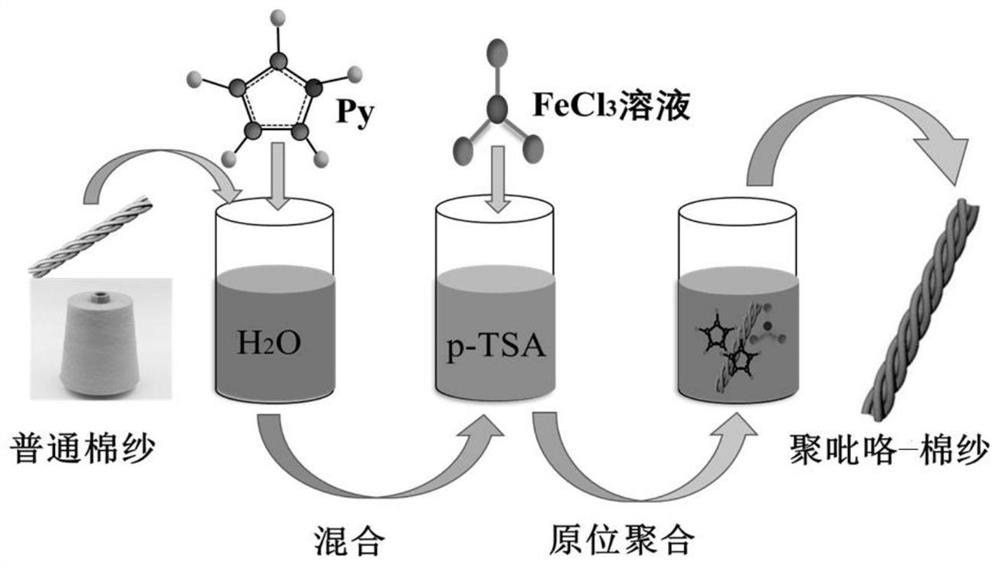

[0040] placing the cotton yarn in the aqueous dispersion of pyrrole monomer to obtain a solution of pyrrole soaked in the cotton yarn;

[0041] FeCl 3 - adding p-toluenesulfonic acid solution dropwise to the pyrrole solution soaked in cotton yarn, and performing in-situ oxidation polymerization to obtain polypyrrole-cotton yarn;

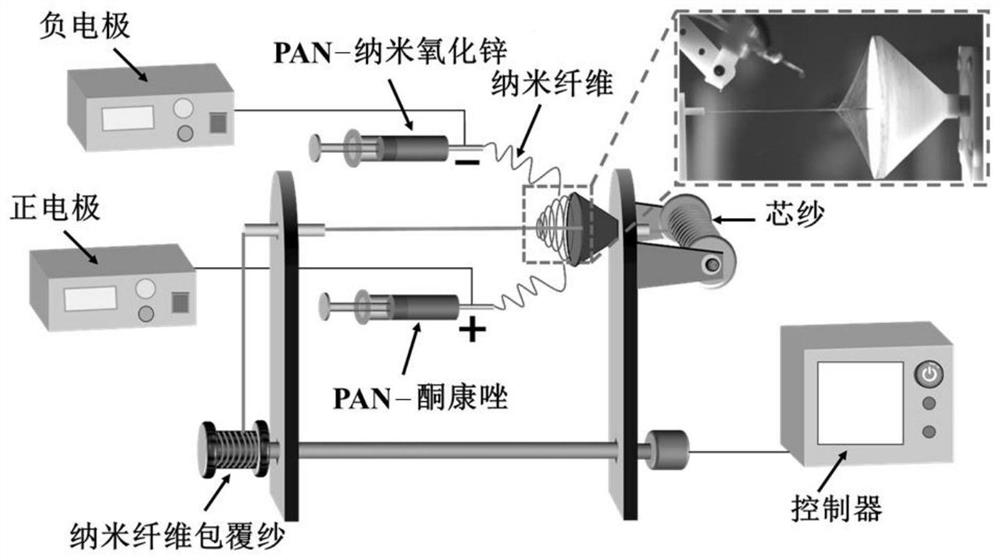

[0042] The polyacrylonitrile-ketoconazole solution is used as the positive electrode electrospinning solution, the polyacrylonitrile-nano zinc oxide solution is used as the negative electrode electrospinning solution, and the polypyrrole-cotton yarn is rotated and coated by double-electrode electrospinning , to obtain nanofiber-coated yarn.

[0043] In the invention, the cotton yarn is placed in the aqueous dispersion liquid of the pyrrole monomer to obtain the pyrrole solution so...

Embodiment 1

[0061] Step (1): Weigh 30g of cotton yarn, soak it in absolute ethanol for 30min, rinse it with deionized water, and let it dry naturally.

[0062] Step (2): According to the bath ratio of cotton yarn and deionized water as 1:60, measure 1800mL of deionized water, add 54.27g of pyrrole monomer dropwise, stir until it is evenly dispersed in deionized water, and then put the cotton yarn into the above-mentioned pyrrole monomer aqueous dispersion, stirred for 5 minutes and soaked for 30 minutes to obtain the pyrrole solution soaked in cotton yarn.

[0063] Step (3): According to the amount of pyrrole, according to FeCl 3 The mass ratio of pyrrole to 3:2 weighs FeCl 3 , calculate and weigh 171.198g of p-toluenesulfonic acid, FeCl 3 and p-toluenesulfonic acid were poured into 1800mL deionized water, and magnetically stirred for 30min until completely dissolved to obtain FeCl 3 - p-toluenesulfonic acid solution.

[0064] Step (4): Place the pyrrole solution soaked in cotton yarn...

Embodiment 2

[0069] Step (1): Weigh 30g of cotton yarn, soak it in absolute ethanol for 30min, rinse it with deionized water, and let it dry naturally.

[0070] Step (2): According to the bath ratio of cotton yarn and deionized water as 1:60, measure 1800mL of deionized water, add 54.27g of pyrrole monomer dropwise, stir until it is evenly dispersed in deionized water, and then put the cotton yarn into the above-mentioned pyrrole monomer aqueous dispersion, stirred for 5 minutes and soaked for 30 minutes to obtain the pyrrole solution soaked in cotton yarn.

[0071] Step (3): According to the amount of pyrrole, according to FeCl 3 The mass ratio of pyrrole to 3:2 weighs FeCl 3 , calculate and weigh 171.198g of p-toluenesulfonic acid, FeCl 3 and p-toluenesulfonic acid were poured into 1800mL deionized water, and magnetically stirred for 30min until completely dissolved to obtain FeCl 3 - p-toluenesulfonic acid solution.

[0072] Step (4): Place the pyrrole solution soaked in cotton yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com