Preparation method of silver-tungsten composite copper alloy electric contact material

A technology of electrical contact material and silver layer, applied in the direction of contact material, metal material coating process, contact, etc., can solve the problems of affecting the bonding strength of copper and silver interface, increasing the amount of silver powder, and low bonding strength, etc., to achieve shortening The effect of production cycle, improved density, and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

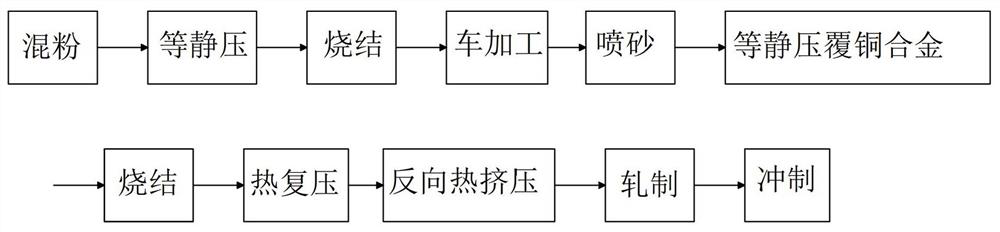

[0034] A preparation method of a silver-tungsten clad copper alloy electrical contact material, the preparation process is as follows figure 1 shown, including the following steps:

[0035] (1) According to parts by mass, 40 parts of tungsten, 2 parts of Ni, 1 part of La 2 o 3 , 57 parts of silver dry mixed, after mixing for 1.5h, mixed powder was obtained. The mixed powder is pressed into an ingot in an isostatic pressing device, the diameter of the ingot is 60 mm, the length is 150 mm, and the isostatic pressing pressure is 50 MPa. The ingot was sintered in a hydrogen atmosphere, the sintering temperature was 850°C, and the sintering time was 6 hours to obtain a silver-tungsten ingot.

[0036] (2) According to parts by mass, 4 parts of diamond and 3 parts of In 2 o 3 , 93 parts of copper were dry mixed, and after mixing for 1.5 hours, copper alloy powder was obtained.

[0037] (3) Sand blast the surface of the silver-tungsten ingot after lathing, the sand blasting meth...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0043] No turning step is performed.

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1, and its difference only lies in:

[0046] Cut off the head and tail of the strip obtained by reverse hot extrusion, and roll it to the required thickness on a cold rolling mill without annealing in the middle. The strip rolled to the desired thickness is punched out of the silver-tungsten / copper alloy electrical contact profile with a stamping die.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com