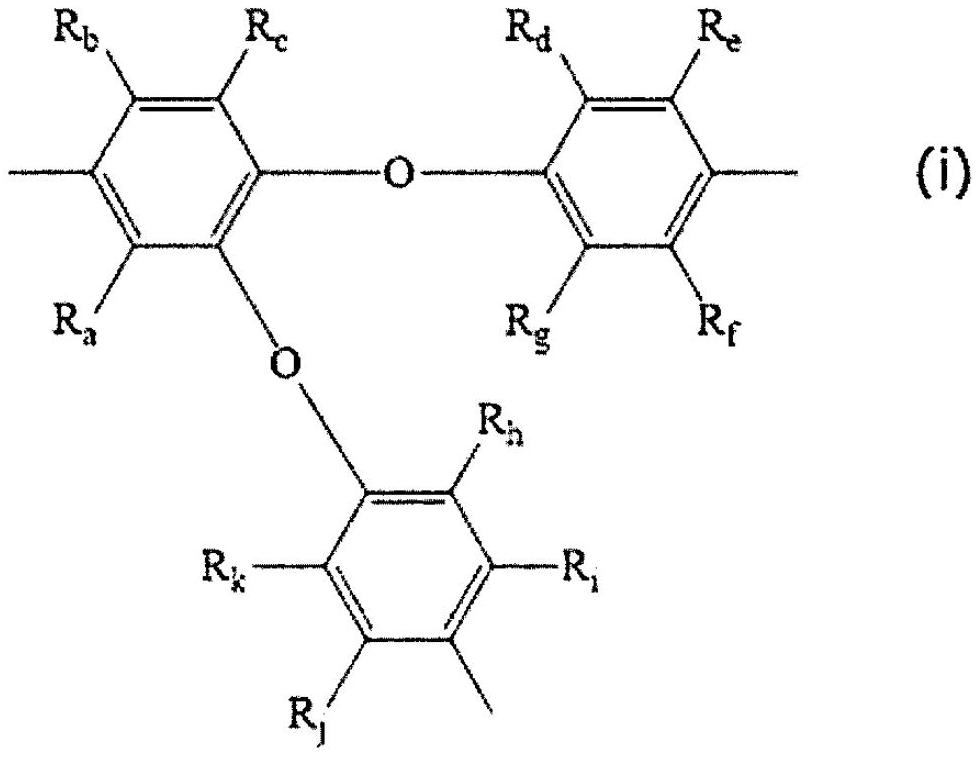

Curable composition containing polyphenylene ether, dry film, preform, cured product, laminate, and electronic component

A technology of curable composition and polyphenylene ether, which is applied in printed circuit components, electrical components, electronic equipment, etc., can solve the problems of increased transmission loss, signal attenuation, heat release, etc., and achieve excellent mechanical properties, excellent low Effect of Dielectric Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0454] To branched PPE resin-1: 17.4 parts by mass and styrene elastomer (Asahi Kasei Corporation: trade name "H1051"): 5.7 parts by mass, add cyclohexanone as a solvent: 60 parts by mass, and mix at 40°C For 30 minutes, stir to completely dissolve.

[0455] To the PPE resin solution thus obtained, TAIC (manufactured by Mitsubishi Chemical Corporation): 11.6 parts by mass and spherical silica (manufactured by Admatechs Corporation: trade name "SC2500-SVJ") were added as a crosslinking type curing agent: 94.4 parts by mass, OP935 (manufactured by Clariant Chemicals Ltd.) as a flame retardant: 11.1 parts by mass, maleimide resin (manufactured by Designer Molecules Inc.: trade name "DMI-7005", Mw=49000, solid content 25 Mass %): 23.2 mass parts, after mixing this, it disperse|distributed with a three-roll mill.

[0456] Finally, 0.58 parts by mass of α,α'-bis(t-butylperoxym-isopropyl)benzene (manufactured by NOF Corporation: trade name "PERBUTYL P") was blended as a peroxide, an...

Embodiment 2-8

[0458]

[0459] As shown in Table I-1, the resin compositions of Examples 2-8 and Comparative Examples 1-3 were obtained in the same manner as in Example 1, except that the PPE resin and maleimide resin used and their contents were changed. of varnish.

[0460] The maleimide resins shown in Table I-1 are as follows.

[0461] BMI-689: Made by Designer Molecules Inc., Mw=689

[0462] BMI-3000J: Made by Designer Molecules Inc., Mw=3000

[0463] BMI-1500: Made by Designer Molecules Inc., Mw=1500

[0464]BMI-4000: Made by Daiwa Chemical Industry Co., Ltd., Mw=570

[0465] For the organic solvent of the varnish of each resin composition, when using branched PPE resins soluble in cyclohexanone-1 and 2, use cyclohexanone, and use non-branched PPE resin A that is insoluble in cyclohexanone , In the case of B, use chloroform.

[0466] >

[0467] The following evaluation was performed about the varnish of the resin composition of each Example and each comparative example.

[046...

Embodiment 2-4

[0611]

[0612] As shown in Table III-1, the resin composition of Example 2-4 and Comparative Example 1-2 was obtained similarly to Example 1 except having changed the PPE used, polystyrene copolymer, and its content.

[0613] The reactive styrene copolymers shown in Table III-1 are as follows.

[0614] Product name: Epocros (manufactured by Nippon Shokubai Co., Ltd.)

[0615] Styrene Copolymers Containing Oxazoline Groups

[0616] Number average molecular weight: 70000

[0617] PDI: 2.28

[0618] Oxazoline group amount: 0.27mmol / g

[0619] Product name: SMA Resin (manufactured by Nippon Shokubai Co., Ltd.)

[0620] Styrene copolymers containing anhydride groups (maleic anhydride groups)

[0621] Weight average molecular weight: 14400

[0622] Acid anhydride group amount: 0.27mmol / g

[0623] As the organic solvent of each resin composition, cyclohexanone was used when branched PPE soluble in cyclohexanone was used, and chloroform was used when unbranched PPE insoluble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com