Method for simultaneously preparing nano material and recycling lithium salt by using waste lithium ion battery

A lithium-ion battery and nanomaterial technology, applied in the field of resource recycling, can solve the problems of single metal oxide structure and limited application of energy storage, and achieve the effects of avoiding secondary pollution, easy industrial application, and saving recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

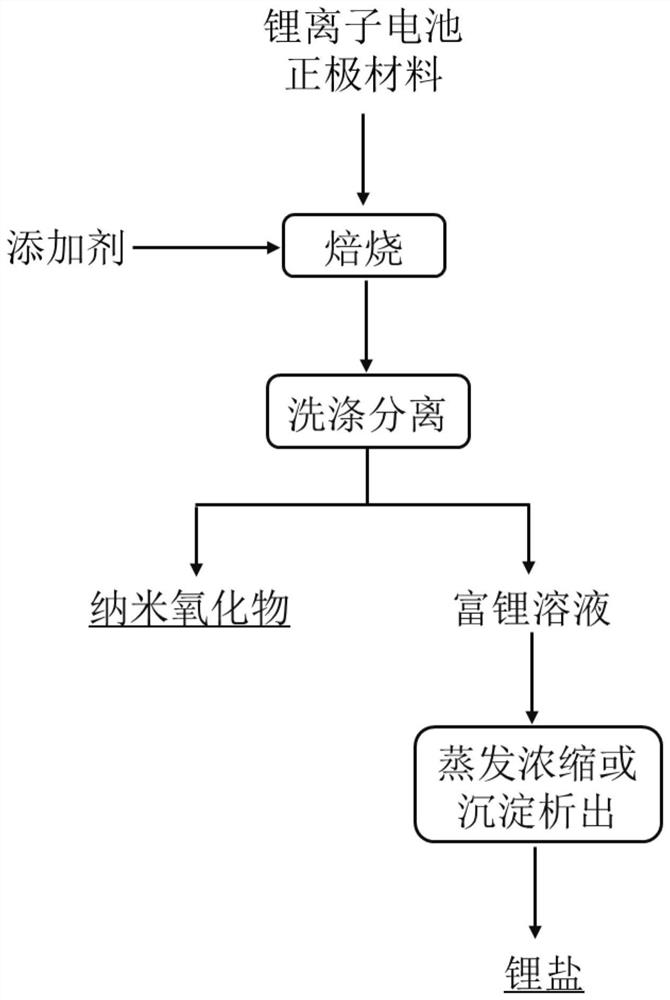

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing nanomaterials by utilizing waste lithium ion batteries. The lithium ion batteries are waste lithium cobalt oxide batteries, and the metal element composition of the positive electrode material is shown in Table 1.

[0055] Table 1 Composition of Metal Elements in Cathode Material of Waste Lithium Cobalt Oxide Battery

[0056] Metal Li Al Ni co mn Content, wt% 6.81 0.52 0.03 59.23 0.01

[0057] The method comprises the steps of:

[0058] (1) After mixing the positive electrode material of lithium cobaltate battery and cobalt sulfate at a molar ratio of 2:1, roasting treatment in an air atmosphere at 500°C for 6 hours;

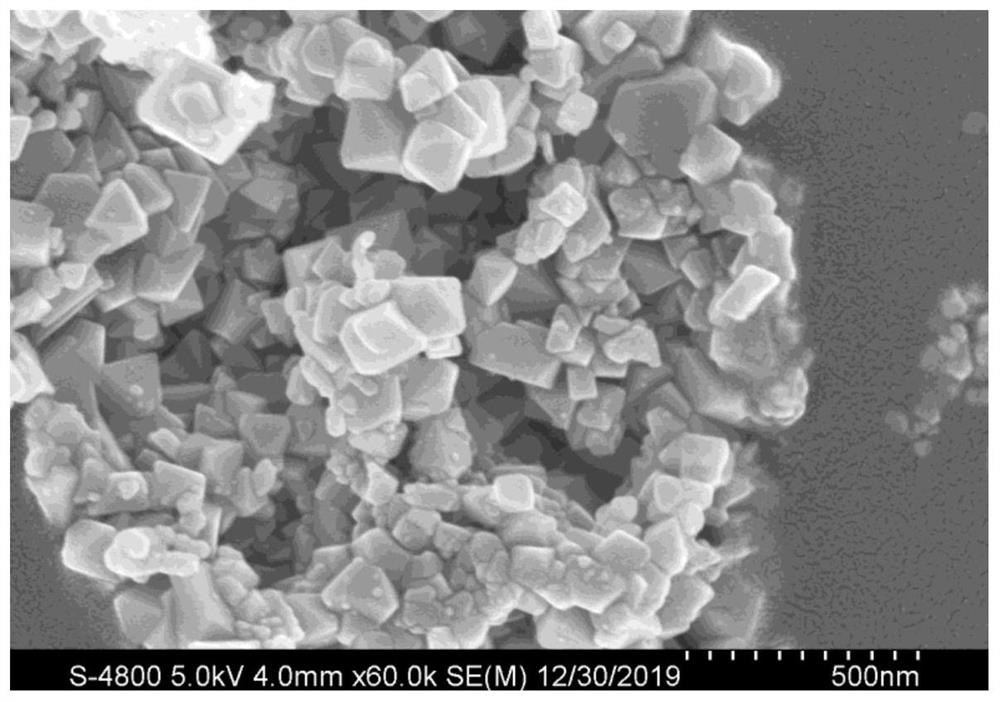

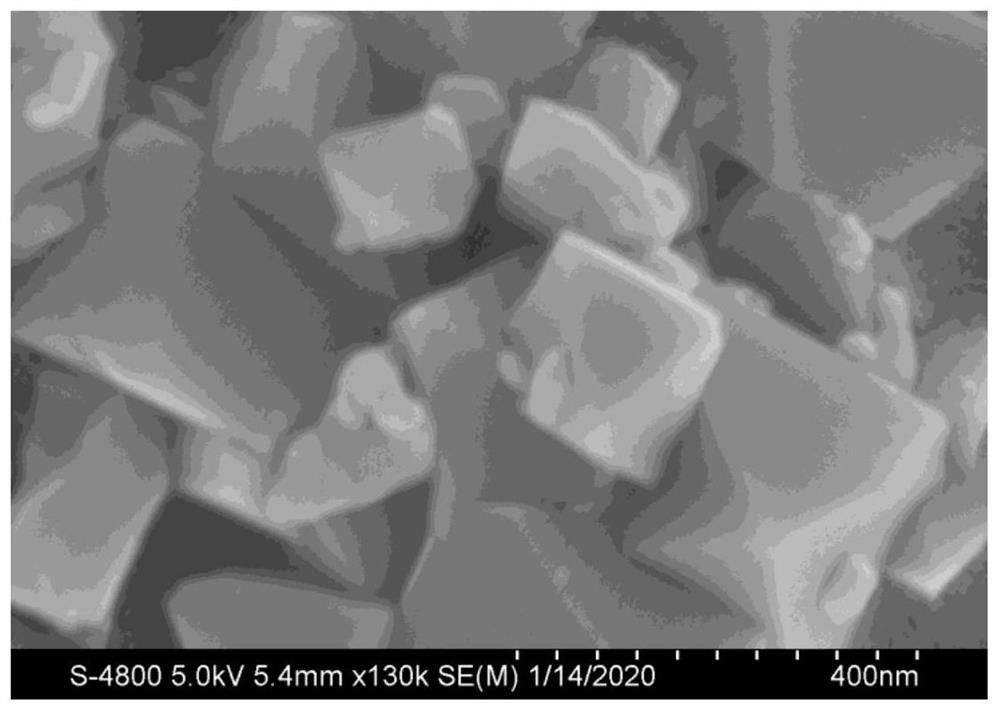

[0059] (2) leaching the roasted product obtained in step (1) with deionized water, and obtaining a transition metal oxide nanomaterial and a lithium-rich solution after filtration and separation;

[0060] (3) The lithium-rich leaching solution obtained in step (2) is concen...

Embodiment 2

[0063] This embodiment provides a method for preparing nanomaterials using waste lithium-ion batteries, the type of the lithium-ion batteries and the composition of the positive electrode material are the same as those in Example 1.

[0064] The method comprises the steps of:

[0065] (1) After mixing the positive electrode material of lithium cobaltate battery and manganese sulfate at a molar ratio of 2:1, roasting treatment for 6 hours in an argon atmosphere at 500°C;

[0066] (2) leaching the roasted product obtained in step (1) with deionized water, and obtaining a transition metal oxide nanomaterial and a lithium-rich solution after filtration and separation;

[0067] (3) Into the lithium-rich leaching solution obtained in step (2) with 5L min -1 Carbon dioxide is introduced at a certain rate, and lithium carbonate is precipitated.

[0068] In the present embodiment, through inductively coupled plasma emission spectroscopy (ICP-OES) detection, the recovery rate of lithi...

Embodiment 3

[0070] This embodiment provides a method for preparing nanomaterials using waste lithium-ion batteries, the type of the lithium-ion batteries and the composition of the positive electrode material are the same as those in Example 1.

[0071] The method comprises the steps of:

[0072] (1) After mixing the positive electrode material of lithium cobalt oxide battery and nickel sulfate at a molar ratio of 2:1, roasting treatment in an air atmosphere at 600°C for 1 hour;

[0073] (2) leaching the roasted product obtained in step (1) with deionized water, and obtaining a transition metal oxide nanomaterial and a lithium-rich solution after filtration and separation;

[0074] (3) The lithium-rich leaching solution obtained in step (2) is concentrated by evaporation to obtain lithium sulfate.

[0075] In this embodiment, through inductively coupled plasma emission spectroscopy (ICP-OES) detection, the recovery rate of lithium in step (3) is calculated to be 98.9%; through X-ray diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com