System and process for recovering ethylene glycol from deicing waste liquid

A technology of waste liquid recovery and ethylene glycol, which is applied in energy wastewater treatment, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of high energy consumption and high cost, reduce energy consumption and cost, and ensure Purity, fully recovered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

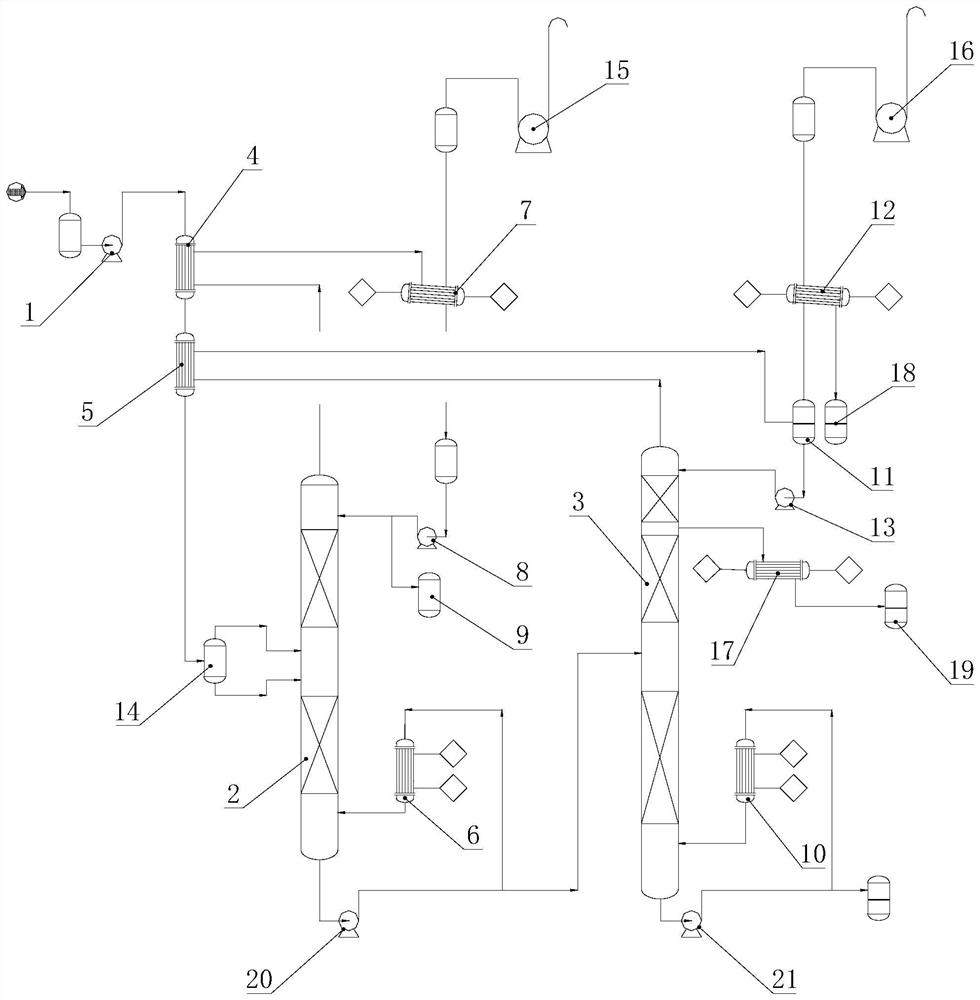

[0035] combined with figure 1 , this embodiment provides a system for recovering ethylene glycol from deicing waste liquid, including a raw material liquid pump 1, a separation tower 2 and a purification tower 3; the liquid outlet end of the raw material liquid pump 1 is connected to the first preheater in sequence 4. The second preheater 5 is connected to the separation column 2; the separation column 2 is fitted with a first reboiler 6, and the gas outlet end of the separation column 2 is sequentially connected to the first preheater 4, the first reboiler 6, and the A condenser 7 is connected to a first circulating pump 8, the liquid outlet end of the first circulating pump 8 is connected to the separation tower 2 and the waste discharge channel respectively, and the liquid outlet end of the separation tower 2 is connected to the purification tower 3 Connected; the purification tower 3 is equipped with a second reboiler 10, and the gas outlet end of the purification tower 3 ...

Embodiment 2

[0044] combine figure 1 , this embodiment provides a system for recovering ethylene glycol from deicing waste liquid. Based on the structure and principle described in Embodiment 1, it also includes a first vacuum pump 15, the first vacuum pump 15 and the first condensation pump 15 The device 7 is connected to the first condenser 7 by the vacuum pump, thereby vacuuming the separation tower 2, on the one hand, the vapor in the separation tower 2 can be discharged in time to improve the separation efficiency, and on the other hand, the separation tower 2 is evacuated by the vacuum pump. Vacuum can reduce the boiling point of the liquid. Compared with direct heating and evaporation under normal pressure, the energy consumption is lower, and the thermal decomposition of the high-boiling point medium can be avoided, thereby improving the purity of the recovered ethylene glycol.

[0045] At the same time, the second vacuum pump 16 is also included, and the second vacuum pump 16 is c...

Embodiment 3

[0048] combine figure 1 , the present embodiment provides a process for recovering ethylene glycol from deicing waste liquid. Based on the structure and principle described in Embodiment 1 or 2, a device is provided between the second preheater 5 and the separation tower 2. There is a second gas-liquid separator 14 to separate the gas and liquid heated by the second preheater 5 through the second gas-liquid separator 14, so that the gas is directly sent to the upper part of the separation tower 2, and the liquid is directly sent to the separation tower. 2 lower part to improve separation efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com