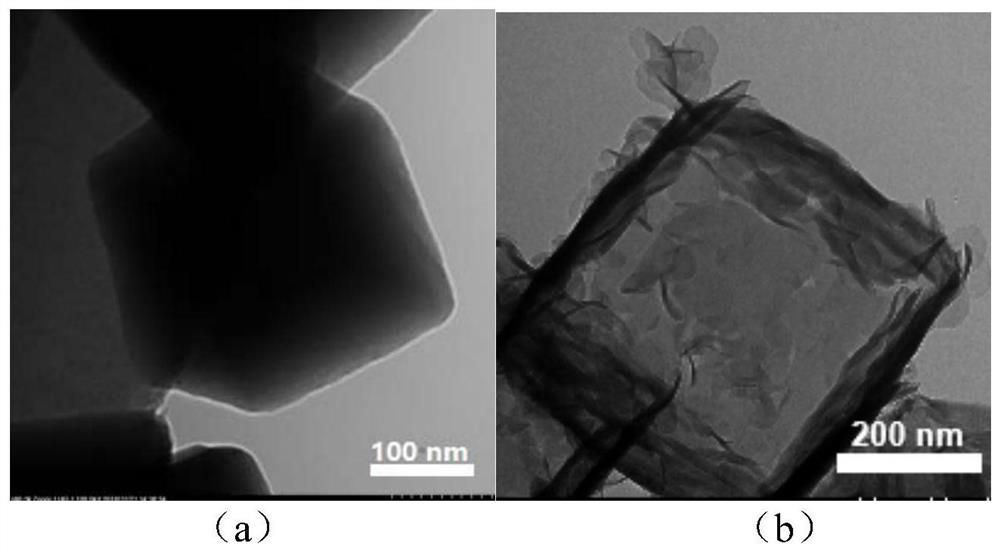

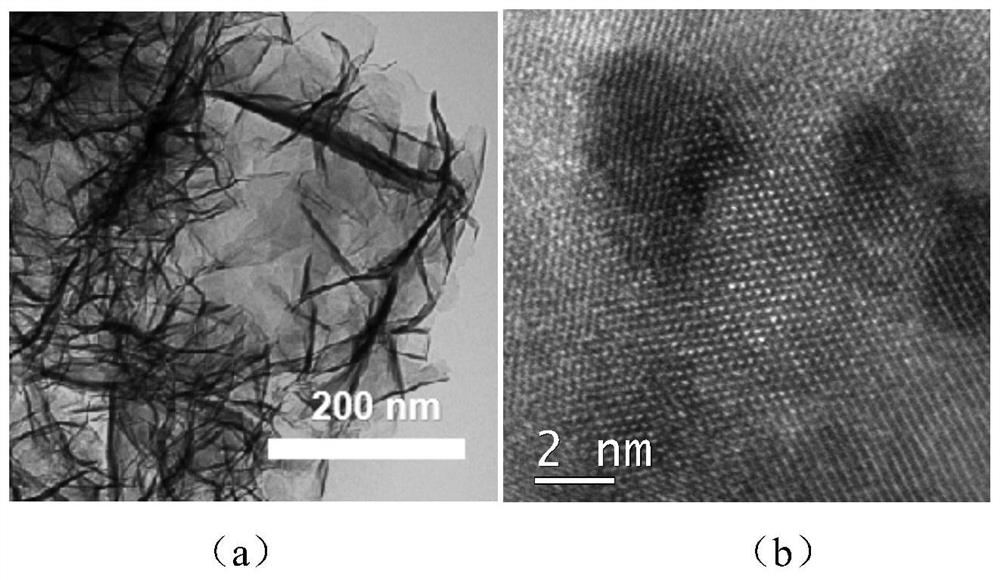

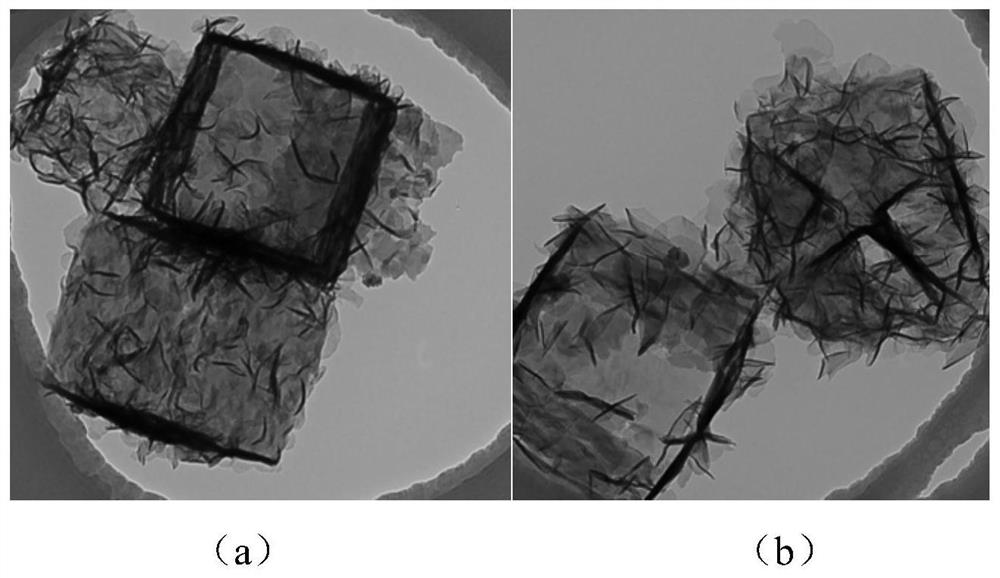

Layered metal hydroxide with nanometer box structure as well as preparation method and application of layered metal hydroxide

A layered metal and hydroxide technology, applied in the field of electrocatalysis, can solve problems such as high temperature, high preparation cost, and complicated preparation methods, and achieve the effects of improved catalytic activity, large specific surface area, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Dissolve 6 mg of cetyl trimethyl ammonium bromide and 240 mg of cobalt nitrate in 8 mL of deionized water with stirring until the solution is clear and transparent;

[0047] 2. Dissolve 3.5g of dimethylimidazole in 56mL of water with stirring until the solution is clear and transparent;

[0048] 3. Add the solution obtained in step 1 to the solution obtained in step 2, and stir at room temperature for 20 min;

[0049] 4. Centrifuge the solution obtained in step 3, and after centrifugation, the obtained solid precipitate is washed with ethanol for 3 times and then dissolved in 120 mL of ethanol solution for subsequent use;

[0050] 5. Dissolve 200 mg of cobalt nitrate in water with stirring;

[0051] 6. Pour the solutions obtained in steps 4 and 5 into a round-bottomed flask, mix well, hydrothermally react at 80°C for 2 hours, and then centrifuge to separate solid-liquid;

[0052] 7. The solid obtained by centrifugation in step 6 was washed three times with water and ...

Embodiment 2

[0055] 1. Dissolve 6 mg of cetyl trimethyl ammonium bromide and 240 mg of cobalt nitrate in 8 mL of deionized water with stirring until the solution is clear and transparent;

[0056] 2. Dissolve 3.5g of dimethylimidazole in 56mL of water with stirring until the solution is clear and transparent;

[0057] 3. Add the solution obtained in step 1 to the solution obtained in step 2, and stir at room temperature for 20 min;

[0058] 4. Centrifuge the solution obtained in step 3, and after centrifugation, the obtained solid precipitate is washed with ethanol for 3 times and then dissolved in 120 mL of ethanol solution for subsequent use;

[0059] 5. Dissolve 100 mg of molybdate in water with stirring;

[0060] 6. Pour the solutions obtained in steps 4 and 5 into a round-bottomed flask, mix well, hydrothermally react at 80°C for 2 hours, and then centrifuge to separate solid-liquid;

[0061] 7. The solid obtained by centrifugation in step 6 was washed three times with water and eth...

Embodiment 3

[0065] 1. Dissolve 6 mg of cetyl trimethyl ammonium bromide and 240 mg of cobalt nitrate in 8 mL of deionized water with stirring until the solution is clear and transparent;

[0066] 2. Dissolve 3.5g of dimethylimidazole in 56mL of water with stirring until the solution is clear and transparent;

[0067] 3. Add the solution obtained in step 1 to the solution obtained in step 2, and stir at room temperature for 20 min;

[0068] 4. Centrifuge the solution obtained in step 3, and after centrifugation, the obtained solid precipitate is washed with ethanol for 3 times and then dissolved in 120 mL of ethanol solution for subsequent use;

[0069] 5. Dissolve 400 mg of molybdate in water with stirring;

[0070] 6. Pour the solutions obtained in steps 4 and 5 into a round-bottomed flask, mix well, hydrothermally react at 80°C for 2 hours, and then centrifuge to separate solid-liquid;

[0071] 7. The solid obtained by centrifugation in step 6 was washed three times with water and eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com