Flexible temperature sensor comprising microstructure and preparation method

A temperature sensor and microstructure technology, applied in sensors, thermometers, thermometers, etc. with electrical/magnetic components directly sensitive to heat, can solve problems such as unfavorable temperature monitoring, artifacts, poor skin fit, etc., to avoid Motion artifacts, improved accuracy, reduced impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Follow the preparation method 31 of a flexible temperature sensor 31 comprising a microstructure, the steps are as follows:

[0041] K1. Preparation of a monolithic substrate with microstructure:

[0042] Select the silicon wafer, clean it, soak it in acetone, and then use ethanol to clean the residual acetone, then wash it with deionized water, blow dry it with nitrogen, bombard the surface of the silicon wafer with argon and oxygen in a plasma cleaning machine, remove the oxide layer, spin the photoresist on the surface of the silicon wafer, and dry it on the heating plate or oven after spinning;

[0043] Photoetching using the first mask version for microstructure positioning as a lithography template:

[0044] K11. Lithography: open the lithography machine, place the first mask version for microstructure positioning as a lithography template on the lithography machine, place the sample on the stage, level the operation, adjust the sample position appropriately so that t...

Embodiment 1

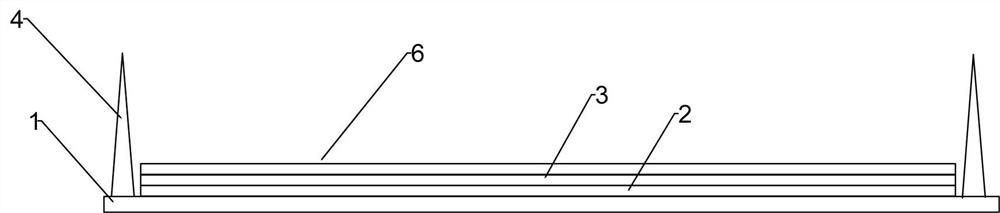

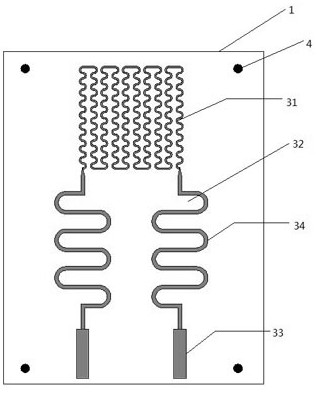

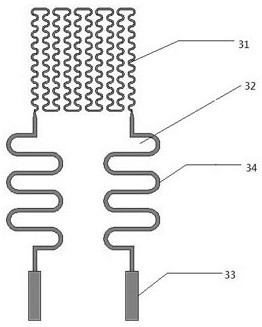

[0065]One kind of flexible temperature sensor 31 comprising a microstructure, comprising a substrate 1 having a cone microstructure disposed sequentially from bottom to top, a first flexible layer 2, a conductive layer 3, a second flexible layer 6, the cone microstructure 4 is integrally molded in the substrate, the top of the cone microstructure 4 is convex from the second flexible layer 6, the conductive layer 3 comprises a temperature sensor 31, an output component 32 for outputting a temperature signal, the output assembly comprises a temperature signal interface 33, One end is connected to the temperature signal interface 33 and the other end is connected to the temperature sensor 31 of the temperature signal output wire 34.

[0066] The cone microstructure 4 comprises at least 4, the cone microstructure 4 is distributed around the temperature sensor 31.

[0067] The height of the cone microstructure 4 is equal.

[0068] The height of the cone microstructure 4 is 80-200 μm.

...

Embodiment 2

[0073] One kind of flexible temperature sensor 31 comprising a microstructure, comprising a substrate 1 having a cone microstructure disposed sequentially from bottom to top, a first flexible layer 2, a conductive layer 3, a second flexible layer 6, the cone microstructure 4 is integrally molded in the substrate, the top of the cone microstructure 4 is convex from the second flexible layer 6, the conductive layer 3 comprises a temperature sensor 31, an output component 32 for outputting a temperature signal, the output assembly comprises a temperature signal interface 33, One end is connected to the temperature signal interface 33 and the other end is connected to the temperature sensor 31 of the temperature signal output wire 34.

[0074] The cone microstructure 4 comprises at least 4, the cone microstructure 4 is distributed around the temperature sensor 31.

[0075] The height of the cone microstructure 4 is equal.

[0076] The height of the cone microstructure 4 is 80-200 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com