Zero-dimensional cerium oxide/three-dimensional porous calcium indium sulfide composite nano material as well as preparation method and application thereof

A composite nanomaterial, zero-dimensional cerium oxide technology, applied in the direction of cerium oxide/cerium hydroxide, lanthanide oxide/hydroxide, rare earth metal oxide/hydroxide, etc., can solve the problem of high-carrier composite efficiency, low quantum efficiency, low efficiency, etc., to achieve the effect of improving catalytic efficiency, high photocatalytic reduction activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

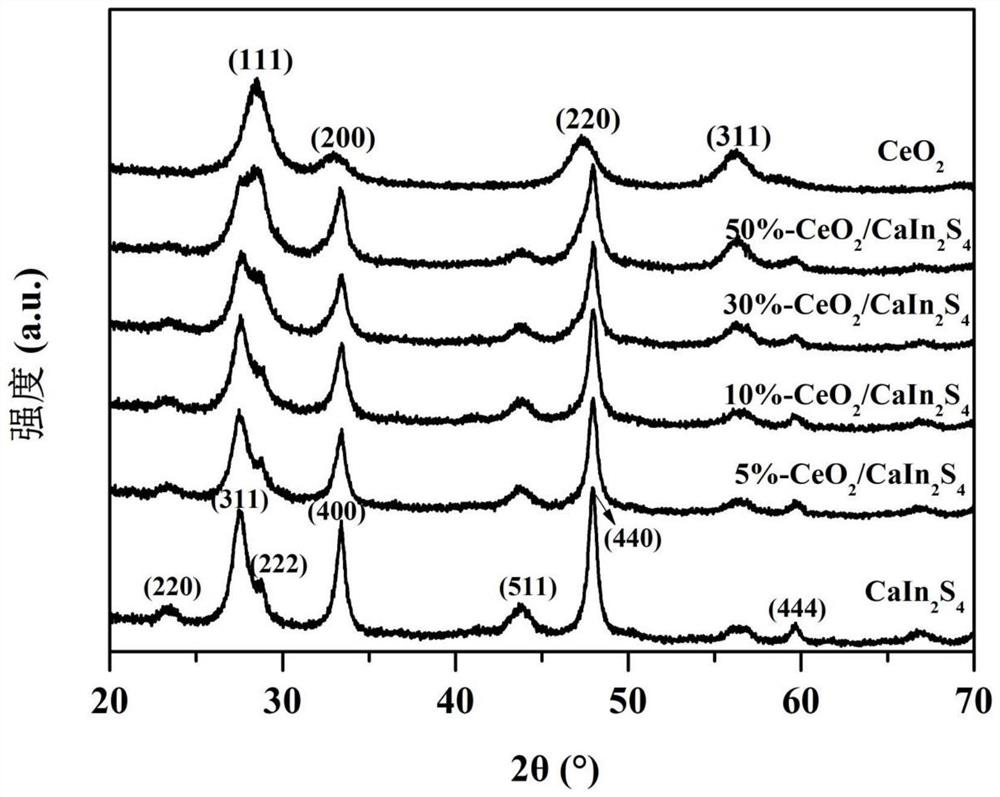

Embodiment 1

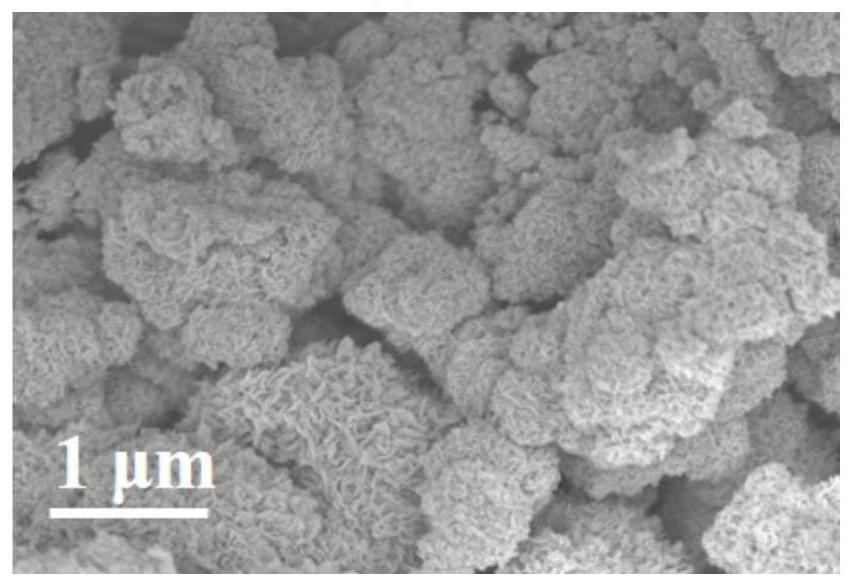

[0036] A three-dimensional nanoflower structure calcium indium sulfide (CaIn 2 S 4 ) Material preparation:

[0037] 0.34g calcium nitrate tetrahydrate, 1.146g indium nitrate tetrahydrate (In(NO) 3 ) 3 ·4.5H 2 O) and 0.9 g of thioacetamide were added to 60 mL of a mixture of water and absolute ethanol (the volume ratio of water and ethanol was 1:1), stirred magnetically for 30 minutes, and then the resulting mixture was transferred to a volume of 100 mL with In a stainless steel autoclave lined with polytetrafluoroethylene, the reaction was carried out at 120 ° C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and the obtained product was mixed with ethanol and deionized water (the volume ratio of water and ethanol was 1:1). ) were centrifuged and washed three times, and dried at 60 °C for 8 h under vacuum to obtain three-dimensional nanoflower-like CaIn 2 S 4 .

Embodiment 2

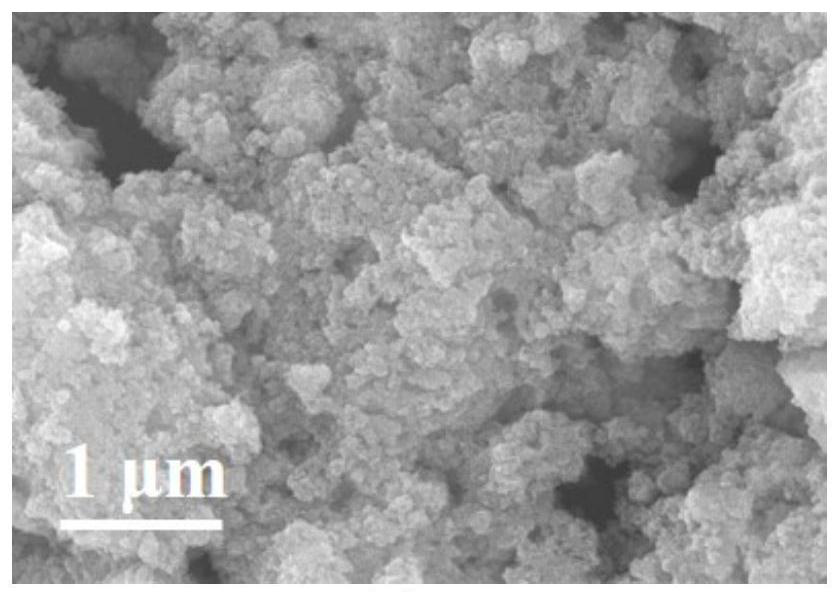

[0039] Zero-dimensional cerium oxide / three-dimensional porous calcium indium sulfide (5% CeO 2 / CaIn 2 S 4 ) Preparation of composite nanomaterials:

[0040] 200 mg of the three-dimensional nanoflower structure calcium indium sulfide (CaIn 2 S 4) The material was ultrasonically dispersed in a mixture of 60 mL of water and anhydrous ethanol (the volume ratio of water and anhydrous ethanol was 1:1), ultrasonically dispersed for 1 h (ultrasonic power was 180 W), continued magnetic stirring for 30 min, and then added 24.6 mg of Hydrate cerium nitrate, after continuous stirring for 30min, add 50 μL of concentrated ammonia water with a concentration of 25wt% dropwise, after ultrasonic dispersion for 30min, continue stirring at room temperature for 3h, the obtained product is a mixture of absolute ethanol and deionized water (the volume ratio of the two) 1:1) Centrifuge and wash several times until neutral, and then place in a 60°C vacuum oven to dry for 12 hours to obtain 5% CeO...

Embodiment 3

[0042] Zero-dimensional cerium oxide / three-dimensional porous calcium indium sulfide (10% CeO 2 / CaIn 2 S 4 ) Preparation of composite nanomaterials:

[0043] 200 mg of the three-dimensional nanoflower structure calcium indium sulfide (CaIn 2 S 4 ) The material was ultrasonically dispersed in a mixture of 60 mL of water and anhydrous ethanol (the volume ratio of water and ethanol was 1:1), ultrasonically dispersed for 1 hour, and then continued magnetic stirring for 30 minutes, then added 49.2 mg of cerium nitrate hexahydrate, and continued stirring for 30 minutes. , 100 μL of concentrated ammonia water with a concentration of 25wt% was added dropwise, and after ultrasonic dispersion for 30 minutes, stirring was continued for 3 hours at room temperature. ℃ dried in a vacuum oven for 12 h to obtain 10% CeO 2 / CaIn 2 S 4 Composite nanomaterials (based on CeO 2 The theoretical addition amount is CaIn 2 S 4 10% of the mass is denoted as 10% CeO 2 / CaIn 2 S 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com