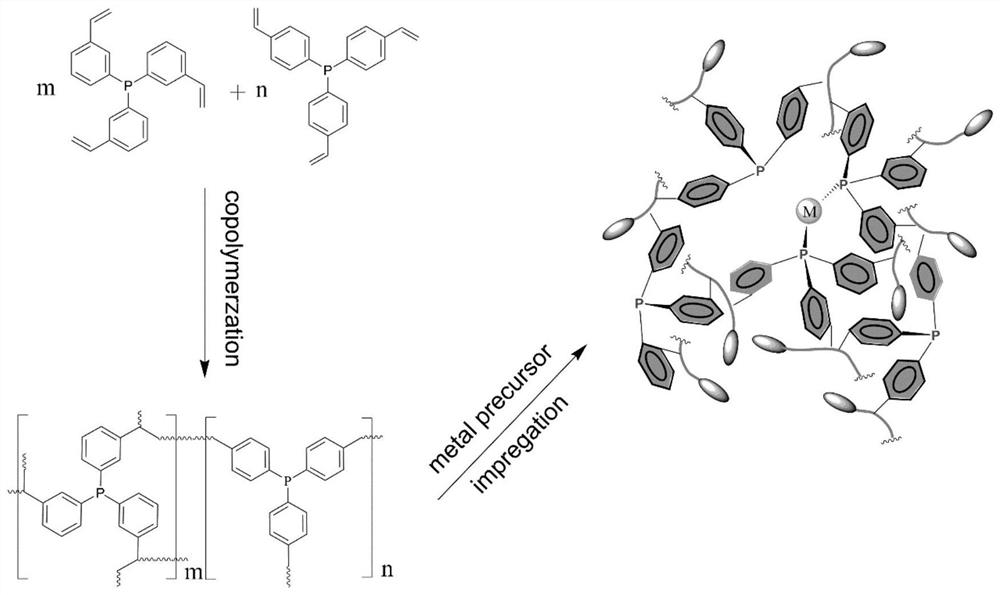

Triphenylphosphine polymer supported catalyst and preparation method thereof

A technology of supported catalyst and triphenylphosphine, which is applied in the field of phosphine-containing porous organic polymer supported catalyst and its preparation, which can solve the problems of fixed structure and performance, achieve high stereoselectivity and improve utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

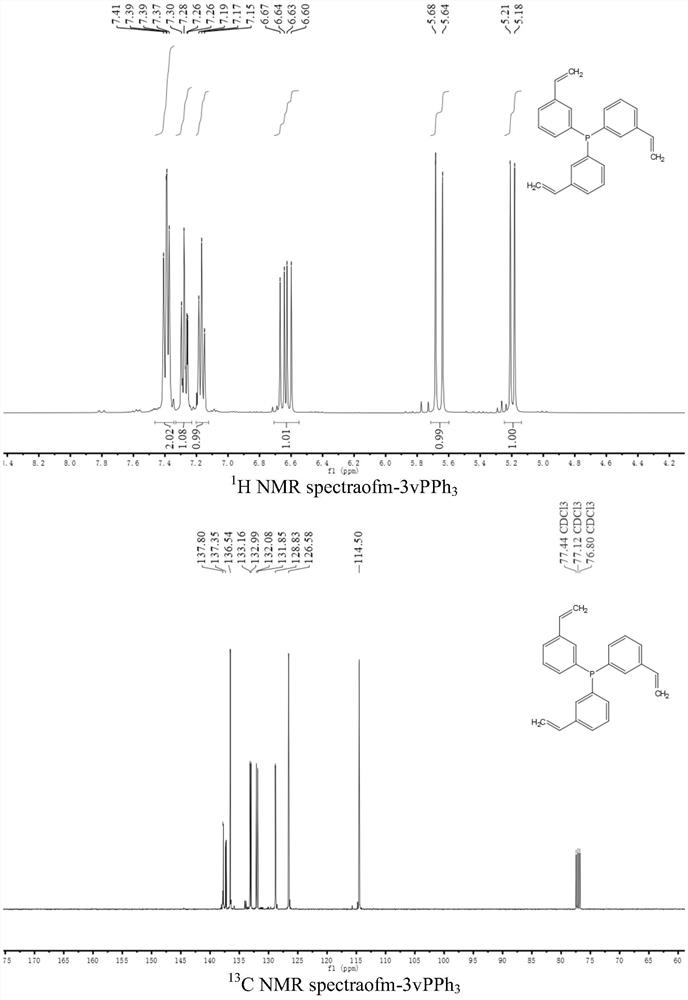

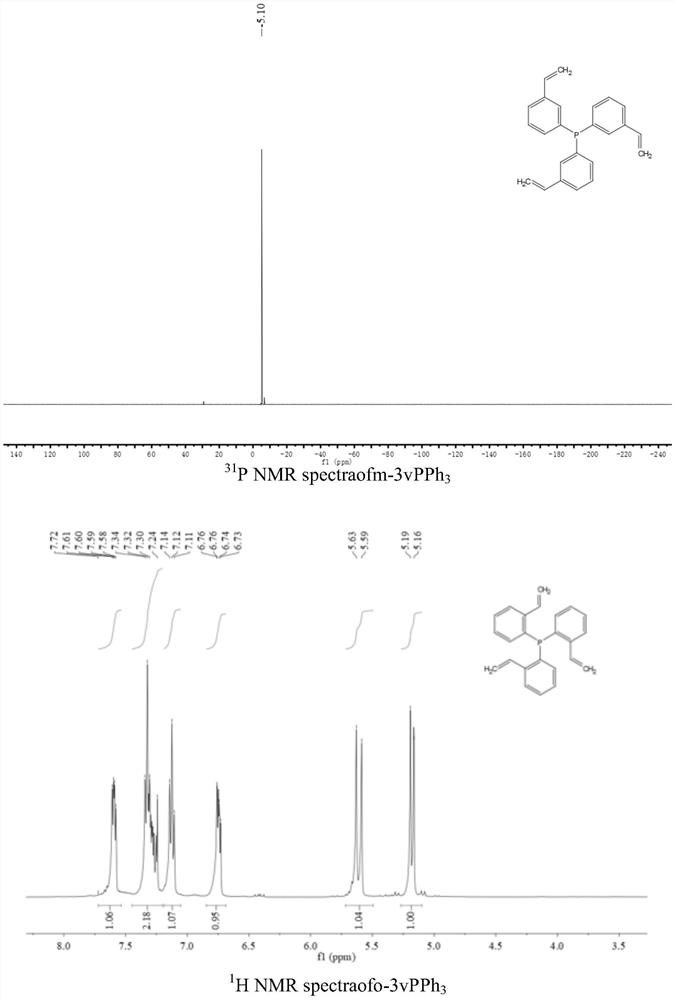

Method used

Image

Examples

Embodiment 1

[0034] Under a nitrogen atmosphere at 298K, 5.0 g of L2 and 5.0 g of L1 were mixed and dissolved in 100 mL of tetrahydrofuran. 1.0 g of free radical initiator azobisisobutyronitrile was added to the above solution and stirred for 2 hours. The stirred solution was transferred to an autoclave and polymerized by solvothermal polymerization at 373K under nitrogen protection atmosphere for 24h. After the above-mentioned polymerized solution is cooled to room temperature, the solvent is vacuumed away at room temperature to obtain a triphenylphosphine mixed polymer carrier. 6.28 mg of rhodium acetylacetonate dicarbonyl was weighed and dissolved in 100.0 ml of tetrahydrofuran solvent, 1.0 g of an organic polymer carrier was added, and the mixture was stirred at 298K under a nitrogen atmosphere for 24 hours, and then the solvent was vacuumed off at room temperature, That is, the catalyst is obtained. The resulting catalyst has a total pore volume of 2.20 cm 3 / g, the proportion of me...

Embodiment 2

[0036]In Example 2, the rest of the catalyst synthesis process was the same as that in Example 1, except that 0.1 g of the radical initiator azobisisobutyronitrile was weighed instead of 1.0 g of the radical initiator azobisisobutyronitrile. The resulting catalyst has a total pore volume of 2.17 cm 3 / g, the proportion of mesopores is 62%.

Embodiment 3

[0038] In Example 3, except that 50.0 ml of tetrahydrofuran solvent was used instead of 100.0 ml of tetrahydrofuran solvent, the rest of the catalyst synthesis process was the same as that of Example 1. The resulting catalyst has a total pore volume of 2.19 cm 3 / g, the proportion of mesopores is 61%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com