Preparation method of high-strength and high-stability vanadium oxide electronic phase change composite ceramic

A composite ceramic and high-stability technology, which is applied in the field of electronic ceramics, sensitive resistance materials and devices, and metal functional semiconductor oxides, can solve the problems of reducing the mechanical properties of materials, increasing the basic resistance of materials, and low mechanical strength to achieve high electronic performance. Effects of stable phase transition function, improved service life, and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

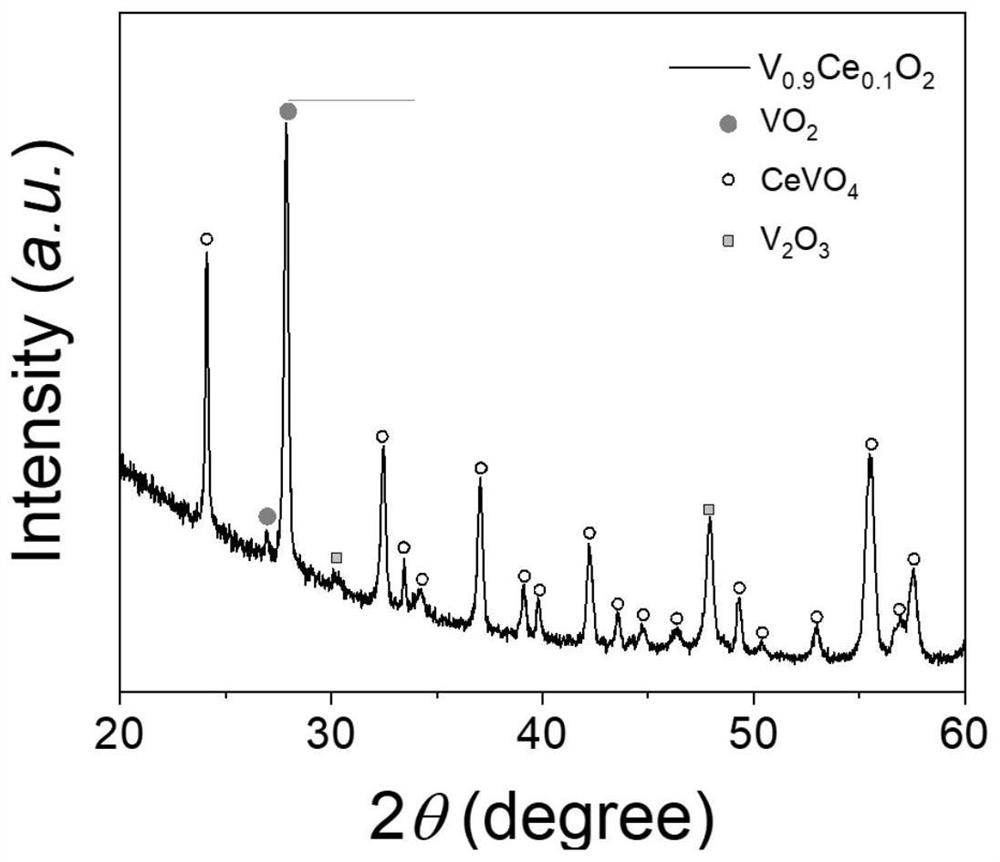

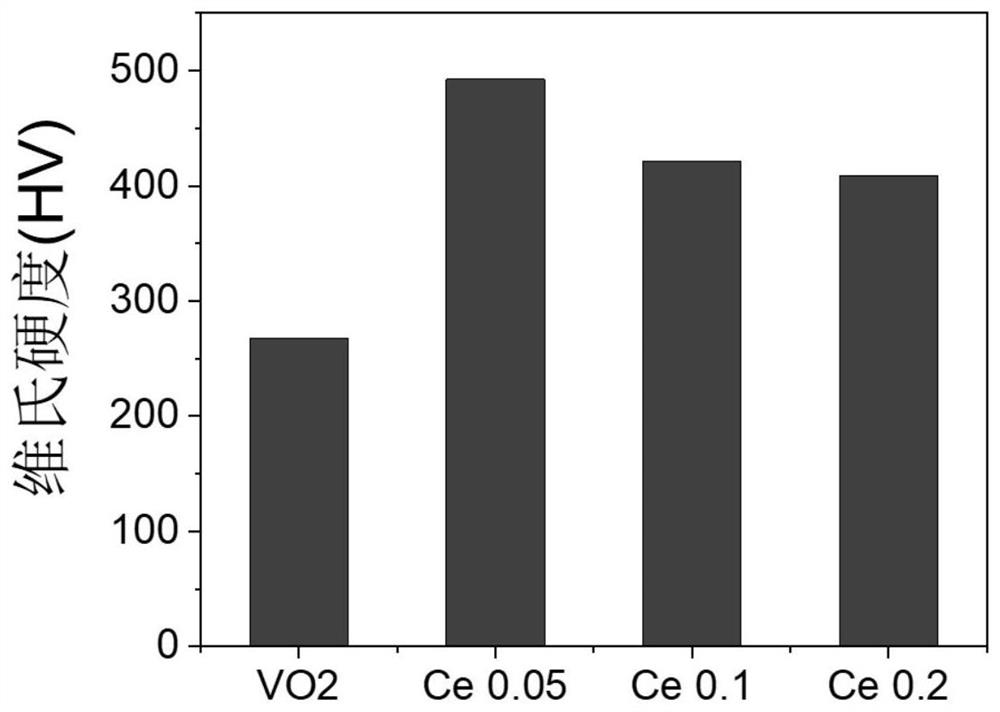

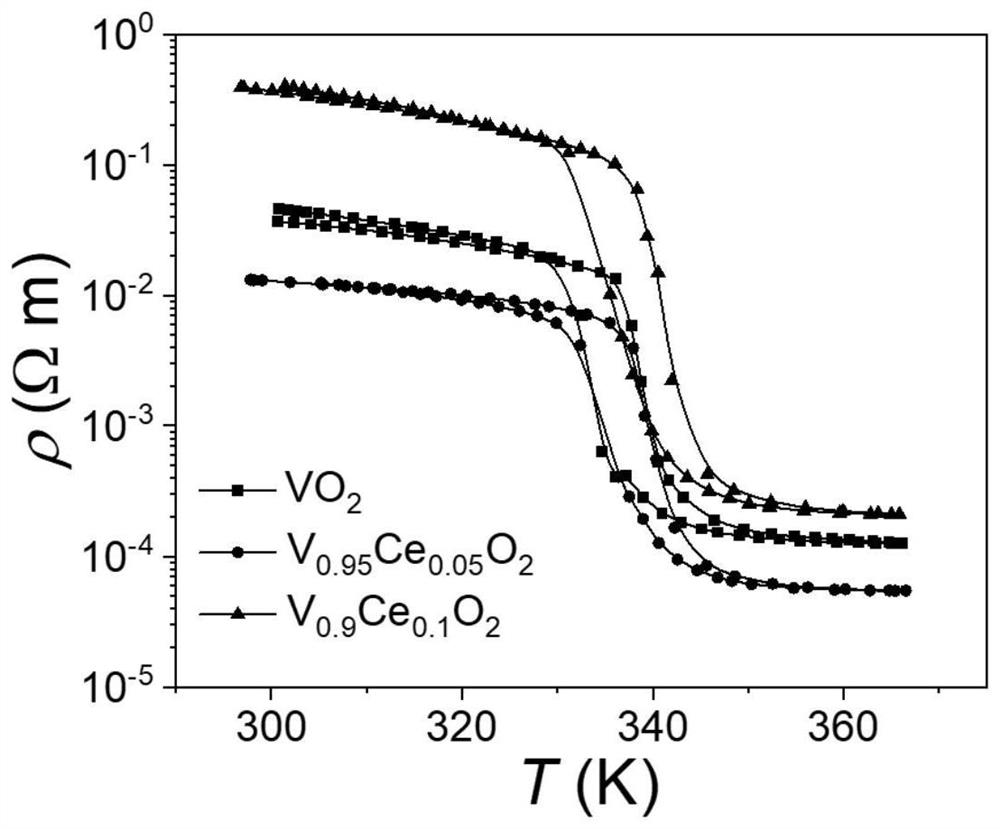

[0023] will VO 2 Powder and CeO 2 The powder is fully ground and mixed uniformly in an agate mortar according to the molar ratio of 9.5:0.5; 9:1; 8:2, and the mixed powder is sintered into a ceramic material in a protective atmosphere, and a pulse current of 300A is applied during the sintering process. Further increase VO 2 The coherence with the composite phase interface and the relative solid-phase reaction degree at the interface between the vanadium oxide parent phase and the composite phase are adjusted, and finally a dense composite ceramic material is obtained. After sintering at a pressure of 2 Mpa and 1300 degrees Celsius for 100 minutes, a composite ceramic material was obtained. The preparation of composite ceramics is mainly composed of vanadium oxide and cerium vanadium oxide, and a small amount of V is also generated during the sintering process. 2 O 3 second phase, such as figure 1 shown. Compared with the bulk material of vanadium dioxide, the hardness o...

Embodiment 2

[0025] will VO 2 Powder and Tb 4 O 7 The powder is fully ground and mixed uniformly in an agate mortar, and the mixed powder is sintered into a ceramic material in a protective atmosphere. During the sintering process, a pulse current of 300A is applied, and after sintering at a pressure of 3Mpa and 1200 degrees Celsius for 100 minutes, a composite material is obtained. Ceramic material. Compared with the bulk material of vanadium dioxide, the hardness of composite ceramics has been significantly improved. The curve of resistivity versus temperature was measured, and it was found that the composite ceramics still had typical temperature-induced phase transition characteristics, the phase transition temperature did not change, and the sharpness of phase transition and room temperature resistivity changed at the same time. At the same time, the composite ceramics are mainly composed of oxide composite phases and vanadium oxide grains bridging in space.

Embodiment 3

[0027] will VO 2 Powder and Alumina (Al 2 O 3 ) The powder is fully ground and mixed evenly in an agate mortar, and the mixed powder is sintered into a ceramic material in a protective atmosphere. During the sintering process, a pulse current of 50 and 500 A is applied respectively, and the pressure is 3 Mpa and 1300 degrees Celsius. After a few minutes, a composite ceramic material was obtained. The preparation of composite ceramics is mainly composed of vanadium oxide and aluminum vanadium oxide, and its phase transition temperature is adjustable. The mechanical and thermal cycling resistance of composite ceramic materials with high current application is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com