Lithium ion battery pre-lithiation agent and preparation method and application thereof

A technology of lithium-ion batteries and lithiation agents, applied in the field of lithium-ion batteries, can solve the problems of difficulty in large-scale industrial production and application, poor conductivity and air stability, and high cost of material preparation, so as to improve air stability and improve The effect of conductivity and simple sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

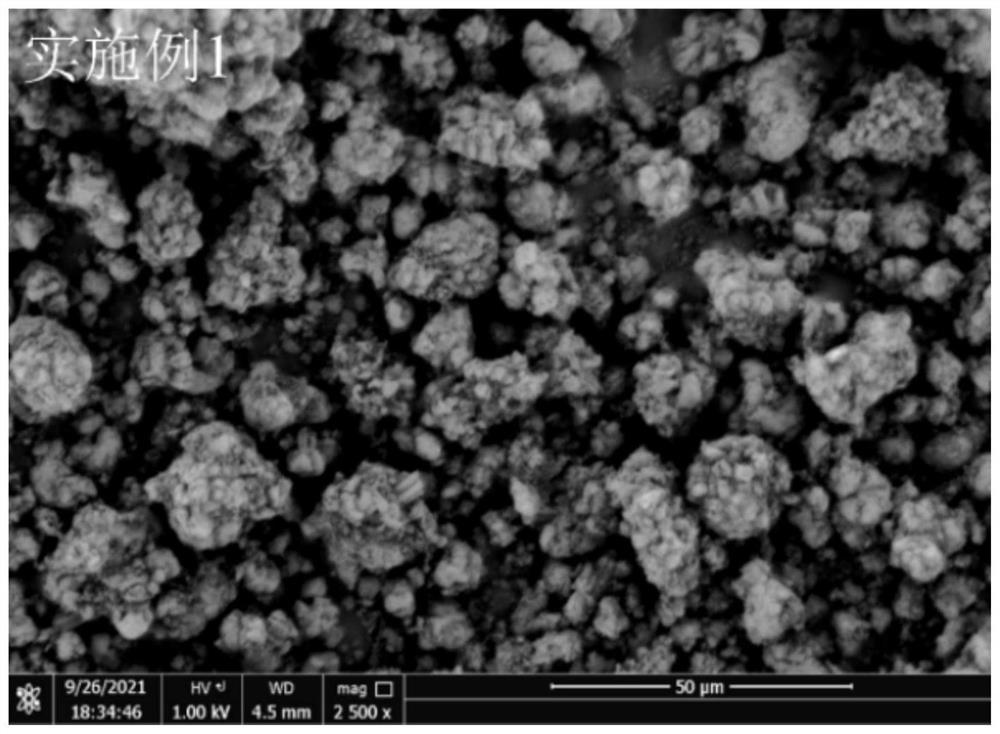

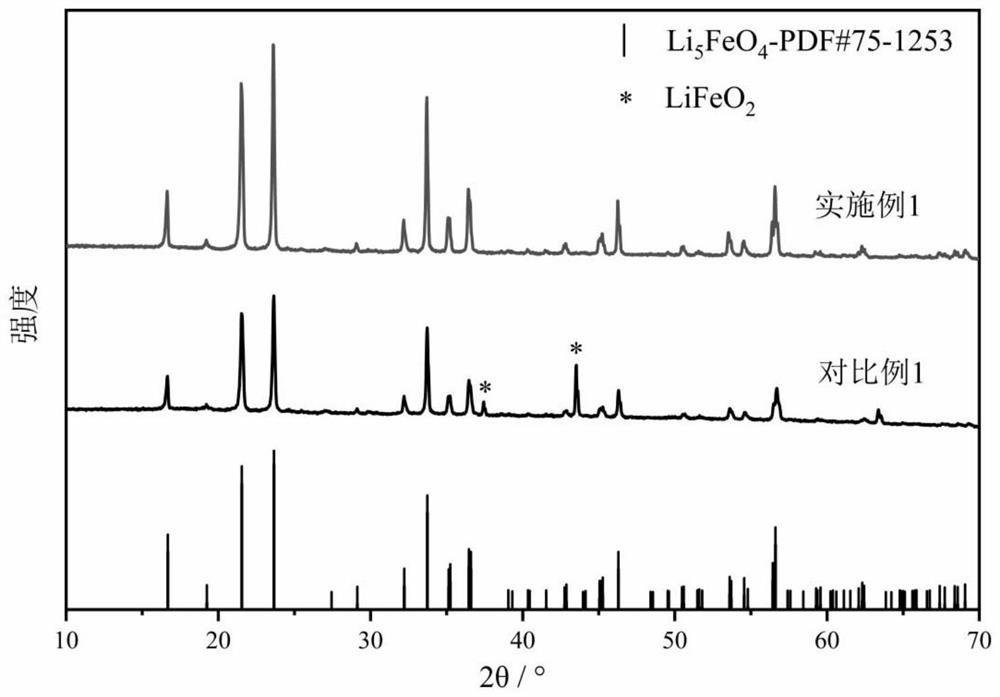

[0038] In this example, a prelithiation agent for lithium ion batteries is prepared, and the chemical formula is Li 5 FeO 4 @C, whose structure is given by Li 5 FeO 4 Secondary particles formed by agglomeration of primary particles, and carbon-coated Li 5 FeO 4 Surface of primary particles, carbon content of 10 wt.%, Li 5 FeO 4 The particle size of primary particles is less than or equal to 10 μm. The specific preparation process is:

[0039] (1) FeCl 3 ·6H2 O and acidified graphene were added to anhydrous ethanol solvent in a molar ratio of C:Fe=0.59:0.41, and mixed solution A was obtained by ultrasonic dispersion, and acidified graphene was prepared by stirring graphene in 10wt.% nitric acid for 1h;

[0040] (2) drip ammonia water to mixed solution A, ammonia water and Fe 3+ The ratio of mol ratio is 3:1, and the process of dripping ammonia water is carried out ultrasonic stirring and dispersing simultaneously, and the mixed solution B of hydroxide and graphene is p...

Embodiment 2

[0044] In this example, a prelithiation agent for lithium ion batteries is prepared, and the chemical formula is Li 5 FeO 4 @C, whose structure is given by Li 5 FeO 4 Secondary particles formed by agglomeration of primary particles, and carbon-coated Li 5 FeO 4 Surface of primary particles, carbon content of 5 wt.%, Li 5 FeO 4 The particle size of primary particles is less than or equal to 10 μm. The specific preparation process is:

[0045] (1) The FeNO 3 ·9H 2 O and acidified polypyrrole in molar ratio C:Fe=0.40:0.54 were added to the mixed solvent with mass ratio of water:ethanol=1:1, and mixed solution A was obtained by ultrasonic dispersion. The acidified polypyrrole was soaked by polypyrrole in 15wt.% It is prepared by stirring in permanganic acid for 2h;

[0046] (2) drip ammonia water to mixed solution A, ammonia water and Fe 3+ The ratio of mol ratio is 2.5:1, and the process of dripping ammonia water is carried out ultrasonic stirring and dispersing simult...

Embodiment 3

[0050] In this example, a prelithiation agent for lithium ion batteries is prepared, and the chemical formula is Li 5 FeO 4 @C, whose structure is given by Li 5 FeO 4 Secondary particles formed by agglomeration of primary particles, and carbon-coated Li 5 FeO 4 Surface of primary particles, carbon content of 2 wt.%, Li 5 FeO 4 The particle size of primary particles is less than or equal to 10 μm. The specific preparation process is:

[0051] (1) FeCl 3 ·6H 2 O and acidified carbon nanotubes were added into ethylene glycol solvent in a molar ratio of C:Fe=0.21:0.71, and a mixed solution was obtained by stirring and dispersing. The acidified carbon nanotubes were prepared by immersing carbon nanotubes in 5wt.% perchloric acid and stirring. have to;

[0052] (2) drip ammonia water to mixed solution A, ammonia water and Fe 3+ The ratio of mol ratio is 2:1, and the process of dripping ammonia water is carried out ultrasonic stirring and dispersing simultaneously, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com