Synthesis method of superfine monodisperse nano Ag

A synthetic method, a monodisperse technology, applied in nanotechnology, resistance to vector-borne diseases, etc., can solve the problems of uneven size and high temperature, and achieve the effects of good crystallization, low cost and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

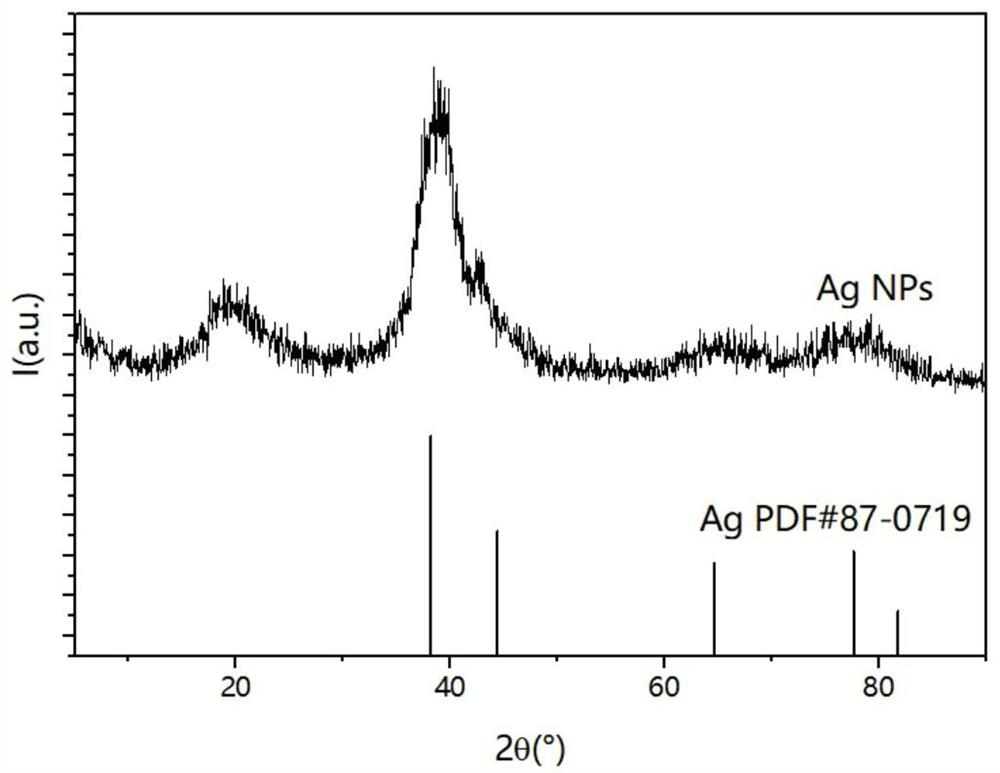

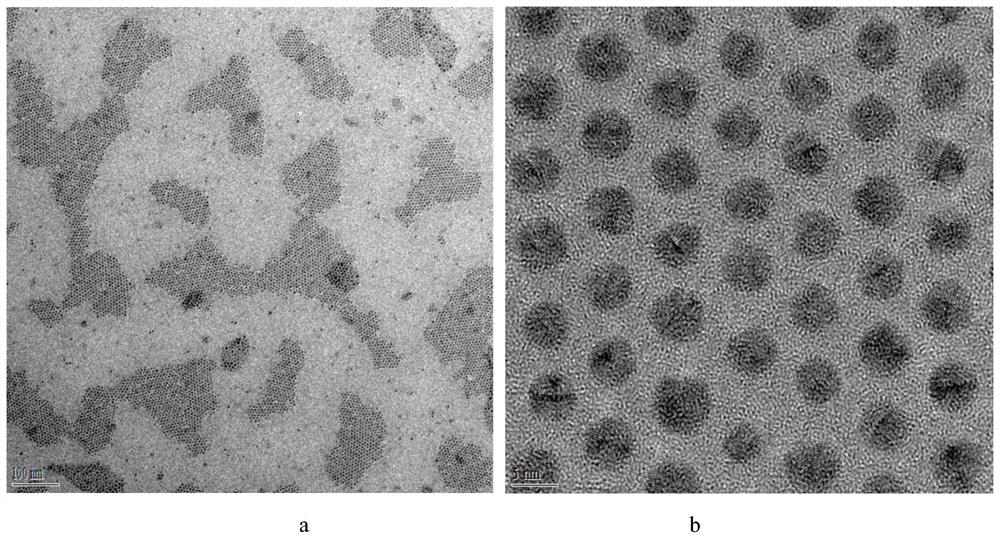

[0037] Get 10ml oleylamine, 2ml sodium oleate and 9ml octadecene are heated to 160 DEG C, drop the silver nitrate of 0.68g into wherein, react 30 minutes, pour out mixed solvents such as oleylamine, sodium oleate and wash the gained with ethanol Precipitate and dry at 40°C for 30 minutes to obtain ultra-fine monodisperse nano-Ag. The obtained products were all characterized by XRD and transmission electron microscopy. Its powder X-ray diffraction spectrum is attached figure 1 shown. Its transmission electron microscope photo is attached figure 2 As shown, most of the synthesized samples are ultra-fine monodisperse nano-Ag powders.

Embodiment 2

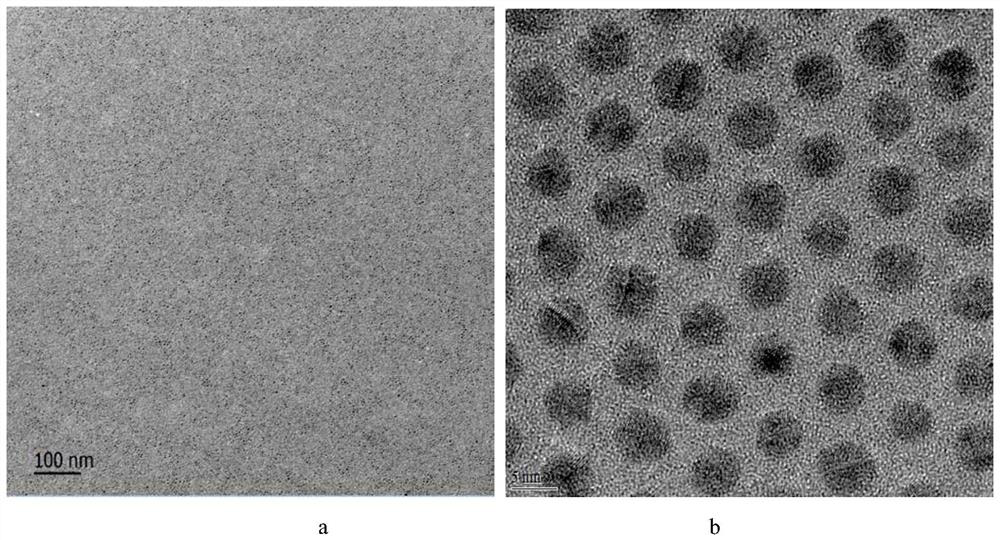

[0039] Get 10ml oleylamine, 1ml oleic acid, 1ml sodium oleate and 10ml octadecene and heat to 200°C, put silver nitrate with a mass of 1.36g into it, react for 20 minutes, pour out oleylamine etc. and wash the resulting precipitate with ethanol, After drying at 40°C for 20 minutes, ultra-fine monodisperse nano-Ag can be obtained. The obtained products were all characterized by XRD and transmission electron microscopy. image 3 As shown, most of the synthesized samples are ultra-fine monodisperse nano-Ag powders.

Embodiment 3

[0041] Get 10ml of octadecylamine and 5ml of sodium oleate and 10ml of octadecene and heat to 180°C, drop into it the silver nitrate with mass of 2.72g, react for 50 minutes, pour out the mixed solvent of octadecylamine and sodium oleate and wash with ethanol The obtained precipitate was dried at 40° C. for 40 minutes to obtain ultra-fine monodisperse nano-Ag. The obtained products were all characterized by XRD and transmission electron microscopy. as attached Figure 4As shown, most of the synthesized samples are ultra-fine monodisperse nano-Ag powders.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com