Nitride epitaxial layer preparation method and semiconductor epitaxial wafer thereof

A nitride epitaxial layer and nitride semiconductor technology, which is applied in semiconductor devices, chemical instruments and methods, and chemically reactive gases, etc., can solve the problems of high dislocation density of crystal materials, restricting applications, and potential safety hazards. The effect of improving uniformity and nucleation density, facilitating large-scale production and reducing the risk of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

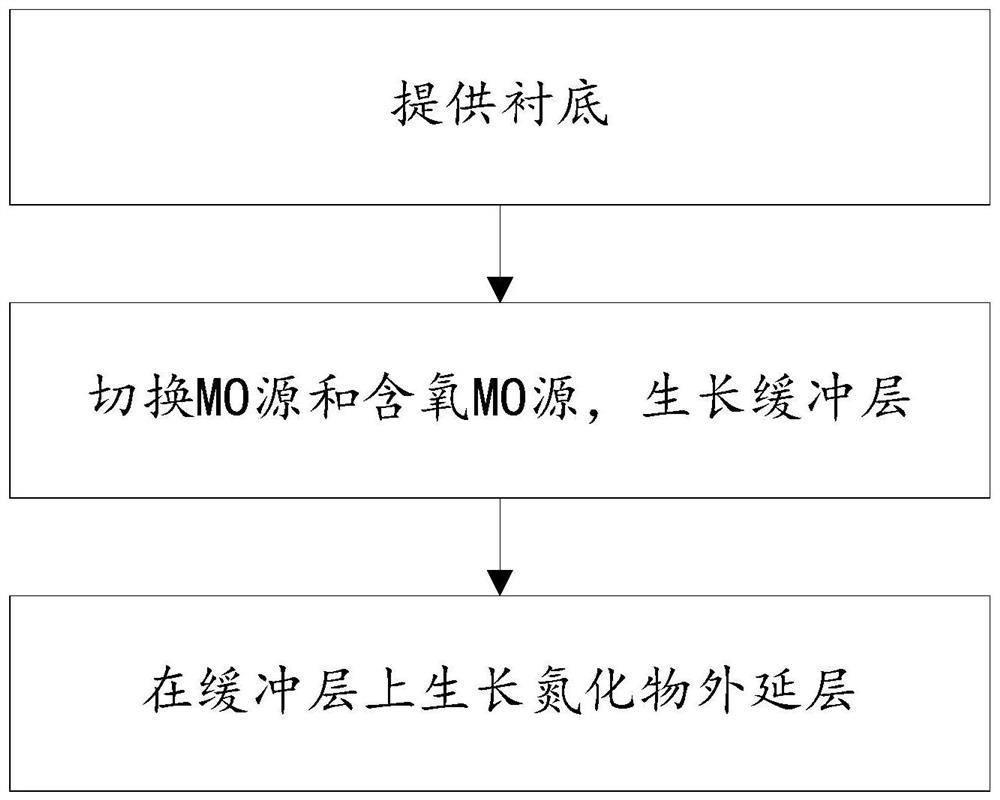

[0037] like figure 1 As shown, the present invention provides a method for preparing a nitride epitaxial layer, comprising the following steps:

[0038] S1: Provide substrate;

[0039] S2: growing a buffer layer on the substrate, wherein the buffer layer includes a nitride buffer layer and an oxygen-containing buffer layer grown by alternately switching the MO source and the oxygen-containing MO source as precursor materials through periodic cycles;

[0040] S3: A nitride epitaxial layer is grown on the buffer layer.

[0041] Specifically, in the MOCVD reaction chamber, the preparation method includes the following steps:

[0042] 1) Provide a substrate, under the conditions of temperature 900 ~ 1200 ℃, growth pressure 50 ~ 650torr, H 2 Atmospheric heat treatment for 1 to 10 minutes;

[0043] 2) On the substrate, under the conditions of a temperature of 500-1000° C. and a growth pressure of 50-650 torr, a buffer layer of 10-100 nm is grown, wherein: the growth of the buffe...

Embodiment 1

[0065] In this example, the alternate growth of GaON and GaN buffer layers with oxygen-containing TMG sources and TMG sources, and the preparation of gallium nitride epitaxial layers in Comparative Example 1 and Comparative Example 2 are used to illustrate the effect. All the preparation environments are placed in the MOCVD reaction chamber. Inside.

[0066] In this embodiment, the gallium nitride epitaxial layer is prepared by alternately growing GaON and GaN buffer layers with an oxygen-containing TMG source and a TMG source, including the following steps:

[0067] 1) Provide sapphire substrate, H 2 Atmospheric heat treatment for 5min;

[0068] 2) On the sapphire substrate, at a temperature of 540 °C and a growth pressure of 300 torr, periodically and alternately grow a GaON buffer layer with a thickness of 3 nm and a GaN buffer layer with a thickness of 5 nm for 20 cycles. The source is oxygen-containing TMG source, the growth GaN buffer layer is switched to TMG source, a...

Embodiment 2

[0081]In this example, a gallium nitride epitaxial layer is prepared by alternately growing a buffer layer of GaON and GaN and a pure TMG source with an oxygen content of less than 1 ppm by alternately growing a TMG source containing oxygen and a TMG source to illustrate the effect, which is different from the first example. The difference is that the growth temperature for preparing the gallium nitride epitaxial layer is different, and all the preparation environments are placed in the MOCVD reaction chamber.

[0082] In this embodiment, the gallium nitride epitaxial layer is prepared by alternately growing GaON and GaN buffer layers with an oxygen-containing TMG source and a TMG source, including the following steps:

[0083] 1) Provide sapphire substrate, H 2 Atmospheric heat treatment for 5min;

[0084] 2) On a sapphire substrate, under the conditions of a temperature of 540 °C and a growth pressure of 300 torr, a GaON buffer layer with a thickness of 3 nm and a GaN buffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com