Cable processing technology

A processing technology and cable technology, which is used in the manufacture of insulated cables, cables/conductors, and insulation of conductors/cables, etc., can solve the problems that cables have no flame retardant and anti-ultraviolet effect, electrical signals cannot be transmitted normally, and electromagnetic shielding cannot be resisted. Achieve good flame retardant and anti-ultraviolet effects, save material loss, and facilitate promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

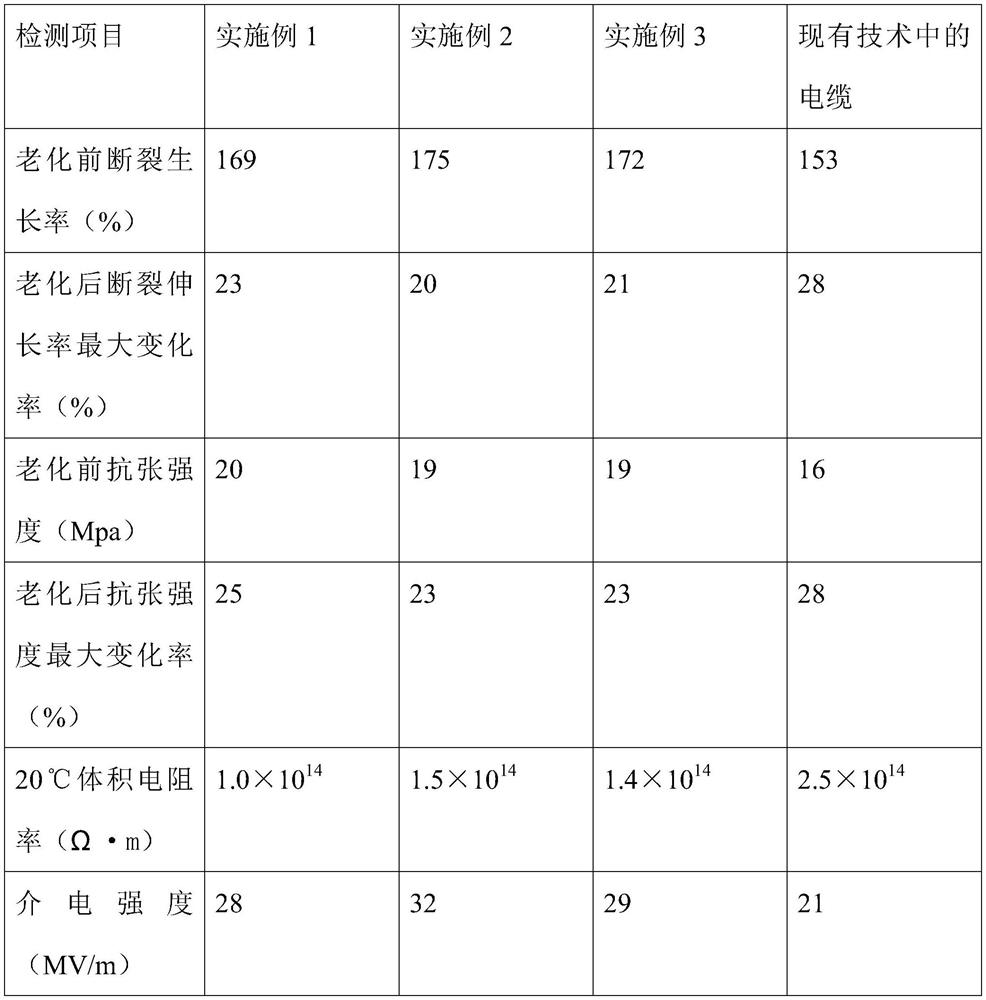

Examples

Embodiment 1

[0025] A cable processing technology, comprising the following steps,

[0026] S1. Preparation of conductor petals: twist a plurality of conductor wires into one strand through a stranding machine, and extrude the semiconductor composite layer through an extrusion die to form the conductor petals;

[0027] S2. Preparation of conductor core: twist several conductor petals and wrap mica tape to form conductor core;

[0028] S3. Preparation of anti-interference layer: select raw materials polyethylene, tinned copper wire, calcium stearate, conductive carbon black, nano-alumina, magnesium, adhesive, antioxidant, methyl silicone oil, silicon dioxide, silicon dioxide Butylated hydroxytoluene and heat resistance mixture, add polyethylene, calcium stearate, nano-alumina, magnesium, silicon dioxide and dibutyl hydroxytoluene into the mixing mixer for stirring. After stirring, add it to the mixing mixer Continue to add tin-plated copper wire, conductive carbon black, and thermal resist...

Embodiment 2

[0040] A cable processing technology, comprising the following steps,

[0041] S1. Preparation of conductor petals: twist a plurality of conductor wires into one strand through a stranding machine, and extrude the semiconductor composite layer through an extrusion die to form the conductor petals;

[0042] S2. Preparation of conductor core: twist several conductor petals and wrap mica tape to form conductor core;

[0043] S3. Preparation of anti-interference layer: select raw materials polyethylene, tinned copper wire, calcium stearate, conductive carbon black, nano-alumina, magnesium, adhesive, antioxidant, methyl silicone oil, silicon dioxide, silicon dioxide Butylated hydroxytoluene and heat resistance mixture, add polyethylene, calcium stearate, nano-alumina, magnesium, silicon dioxide and dibutyl hydroxytoluene into the mixing mixer for stirring. After stirring, add it to the mixing mixer Continue to add tin-plated copper wire, conductive carbon black, and thermal resist...

Embodiment 3

[0055] A cable processing technology, comprising the following steps,

[0056] S1. Preparation of conductor petals: twist a plurality of conductor wires into one strand through a stranding machine, and extrude the semiconductor composite layer through an extrusion die to form the conductor petals;

[0057] S2. Preparation of conductor core: twist several conductor petals and wrap mica tape to form conductor core;

[0058] S3. Preparation of anti-interference layer: select raw materials polyethylene, tinned copper wire, calcium stearate, conductive carbon black, nano-alumina, magnesium, adhesive, antioxidant, methyl silicone oil, silicon dioxide, silicon dioxide Butylated hydroxytoluene and heat resistance mixture, add polyethylene, calcium stearate, nano-alumina, magnesium, silicon dioxide and dibutyl hydroxytoluene into the mixing mixer for stirring. After stirring, add it to the mixing mixer Continue to add tin-plated copper wire, conductive carbon black, and thermal resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com