Porous reduced graphene oxide, method for producing same, sulfur-carbon composite material comprising same, and lithium secondary battery

A carbon composite material, lithium secondary battery technology, applied in graphene, lithium storage battery, chemical instruments and methods, etc., can solve the problem of difficulty in providing sulfur-carbon composite materials, achieve excellent reactivity, excellent mass transfer, increase The effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The method for preparing porous reduced graphene oxide of the present invention has the advantages of easy content adjustment (scale) and large-scale production. In addition, there is an advantage that the pores in the porous reduced graphene oxide can be easily controlled by controlling the content of the template particles and the temperature of the heat treatment in step (c).

[0085] Sulfur-Carbon Composites

[0086] In addition, the present invention relates to a sulfur-carbon composite material comprising: the above-mentioned porous reduced graphene oxide of the present invention; and sulfur contained in at least a part of the inside and the surface of the porous reduced graphene oxide.

[0087] The porous reduced graphene oxide is the same as described above, and can be produced by the above-described production method.

[0088] The sulfur may be at least one selected from the group consisting of elemental sulfur (S 8 ), organosulfur compounds, Li 2 S n (n≥...

Embodiment 1

[0136] Example 1: Preparation of sulfur-porous reduced graphene oxide (S-porous rGO)

[0137] Aqueous dispersion of graphene oxide (GO, product name SE2430, Sixth Element company) and colloidal solution of polystyrene (PS, diameter: 500 nm to 600 nm) in the ratio of GO:PS=1 g:3 g Mix to prepare an aqueous dispersion.

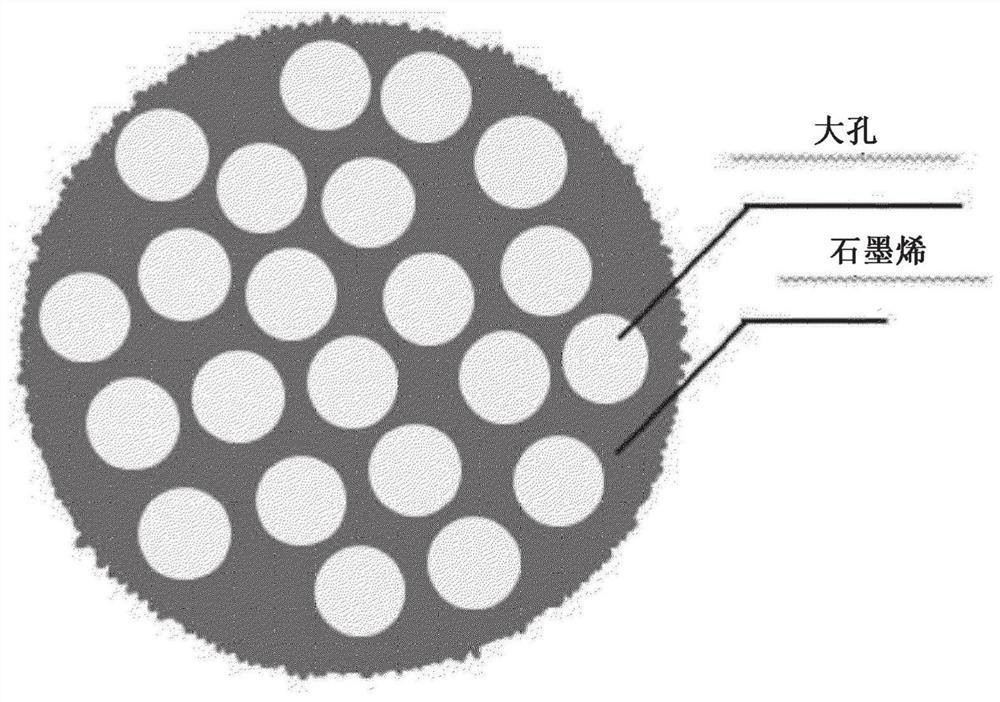

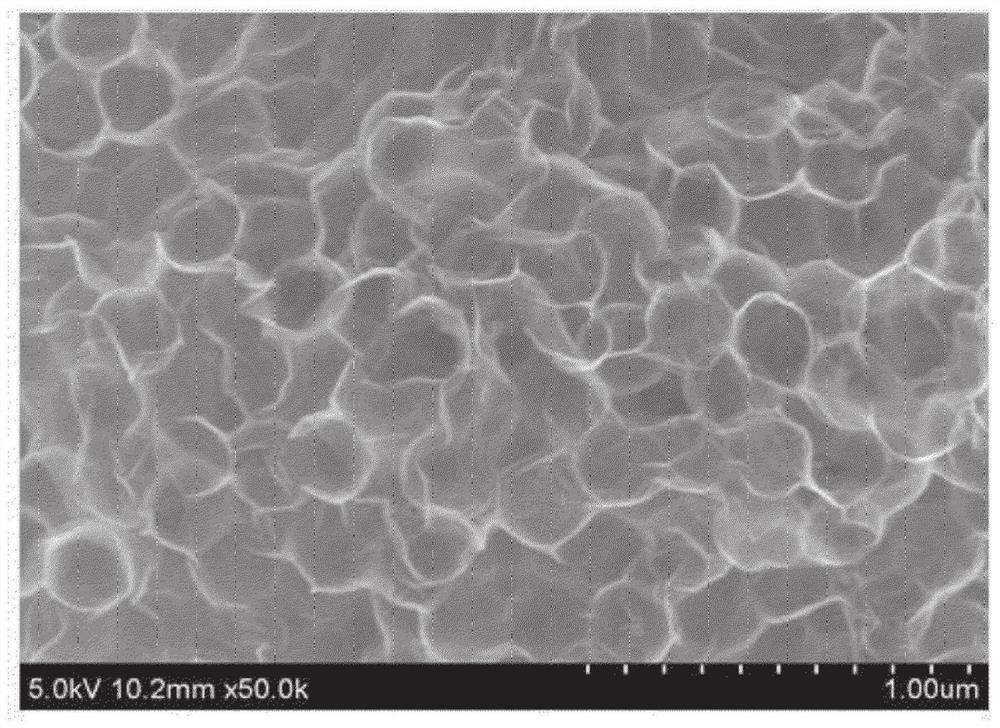

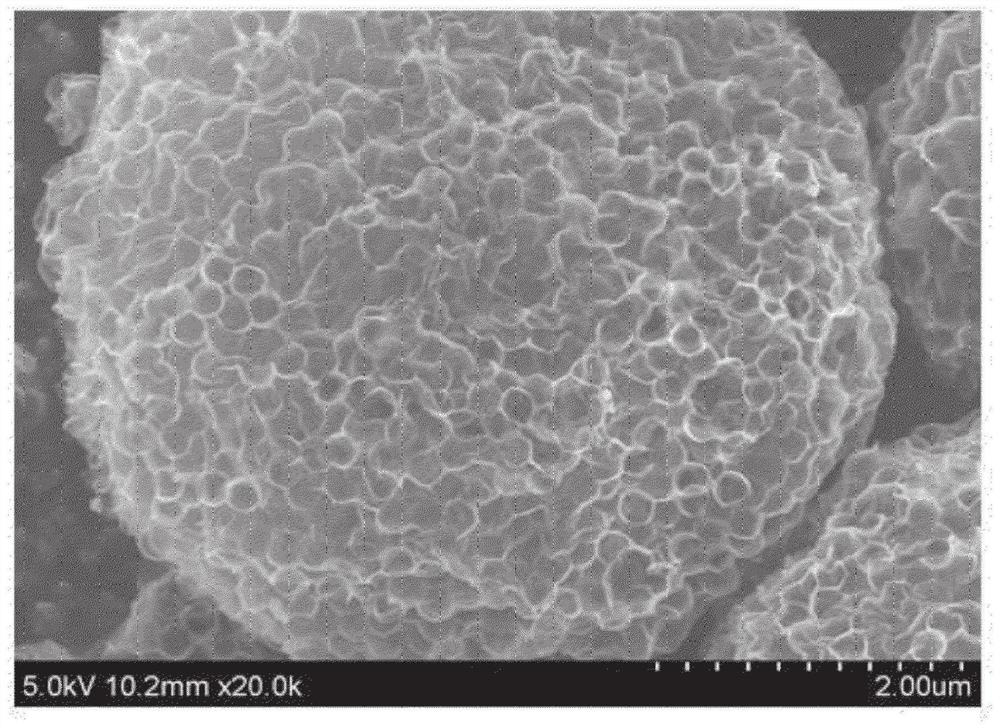

[0138] The dispersion thus prepared was spray-dried at 140° C. (Labplant Corporation, SD-Basic) to prepare a polystyrene-graphene oxide (PS-GO) composite. After recovering the PS-GO composite, it was heat-treated at 500° C. for 4 hours in an argon (Ar) atmosphere (heating for 2 hours and holding for 2 hours), polystyrene was removed, and graphene oxide was reduced to prepare a porous reduced type Graphene oxide (porous rGO) ( Figure 2 to Figure 4 ). The pore diameter is about 15 nm, and the porous reduced graphene oxide has a spherical shape with a diameter of about 9 μm.

[0139] Porous reduced graphene oxide and sulfur were mixed in a weight ratio of 25...

experiment example 1

[0151] Experimental Example 1: Measurement of Initial Discharge Capacity of Lithium-Sulfur Battery

[0152] Lithium-sulfur batteries were prepared using the sulfur-carbon composite materials prepared in Example 1 and Comparative Examples 1 to 3, respectively, as positive electrode active materials.

[0153] Each of the sulfur-carbon composite material, the conductive material and the binder was mixed using a ball mill to prepare a slurry for the positive electrode active material. At this time, carbon black was used as the conductive material, and polyethylene oxide (molecular weight 5,000,000 g / mol) was used as the binder, and the mixing ratio based on the weight ratio of the sulfur-carbon composite material:conductive material:binder was 90:5:5.

[0154] The slurry for positive electrode active material was coated on an aluminum current collector and dried to prepare a positive electrode.

[0155] The shape of the positive electrode fabricated by using the sulfur-carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com