Semi-solid material quick drying system

A semi-solid, material technology, used in drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of unfavorable energy saving and emission reduction and large-scale promotion, high production and operating costs, uneven drying and other problems, and achieve Increase drying contact area, increase speed and efficiency, and increase drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

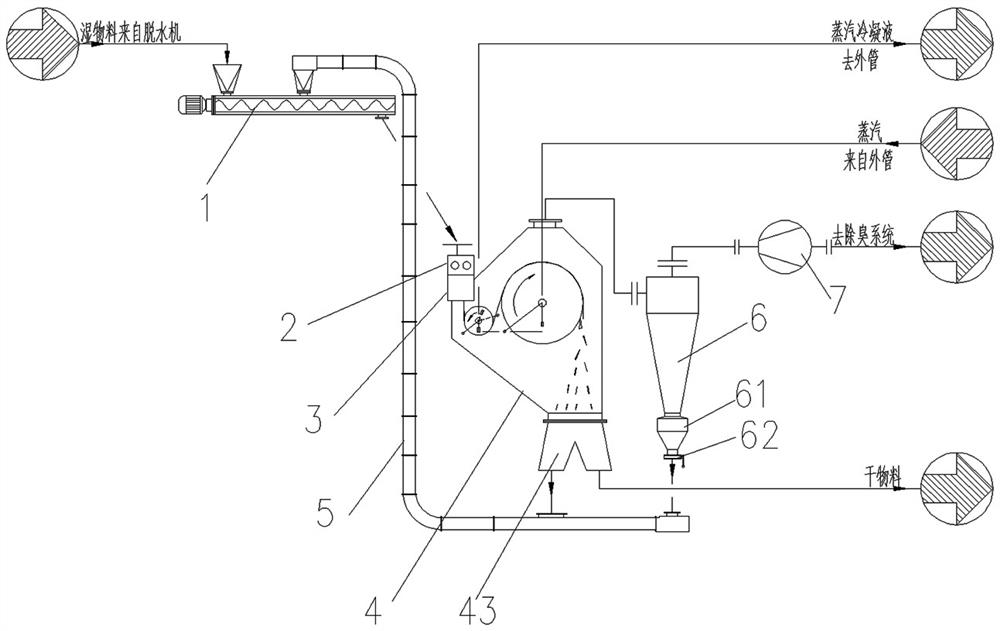

[0037] See figure 1 , a system for rapid drying of semi-solid materials,

[0038] Including shaftless double screw conveyor 1, distributor 2, forming machine 3, dryer 4, chain conveyor 5, cyclone separator 6 and exhaust gas fan 7, the distributor 2 and forming machine 3 are integrated models , the outlet of the cloth machine 2 is directly connected to the inlet of the molding machine 3;

[0039] A pair of stirring shafts 21 are arranged horizontally in the distributing machine 2, and stirring and mixing teeth 22 are evenly arranged on the outer cylindrical surface of each stirring shaft;

[0040] A pair of first rollers 31 , a pair of second rollers 32 and a pair of third rollers 33 are arranged horizontally from top to bottom in the forming machine 3 ;

[0041]Between the corresponding first roller and the stirring shaft, and between the corresponding first roller and the second roller through a chain transmission mechanism; the corresponding second roller and the third rol...

Embodiment 2

[0059] Take the drying treatment equipment in Example 1 as the treatment equipment of this embodiment; take the drying treatment of municipal sludge as an example; the moisture content of the wet sludge after the upstream dehydration is 70-80%, and the sludge treatment capacity is 2t / h ( Dry basis), the initial temperature of the sludge is 25°C at room temperature, the heating steam pressure of the dryer 4 is 0.6MPa, and the temperature is 150-165°C, which specifically includes the following steps:

[0060] Step (1): Start the exhaust fan 7, and the system pressure is stable after about 3 minutes;

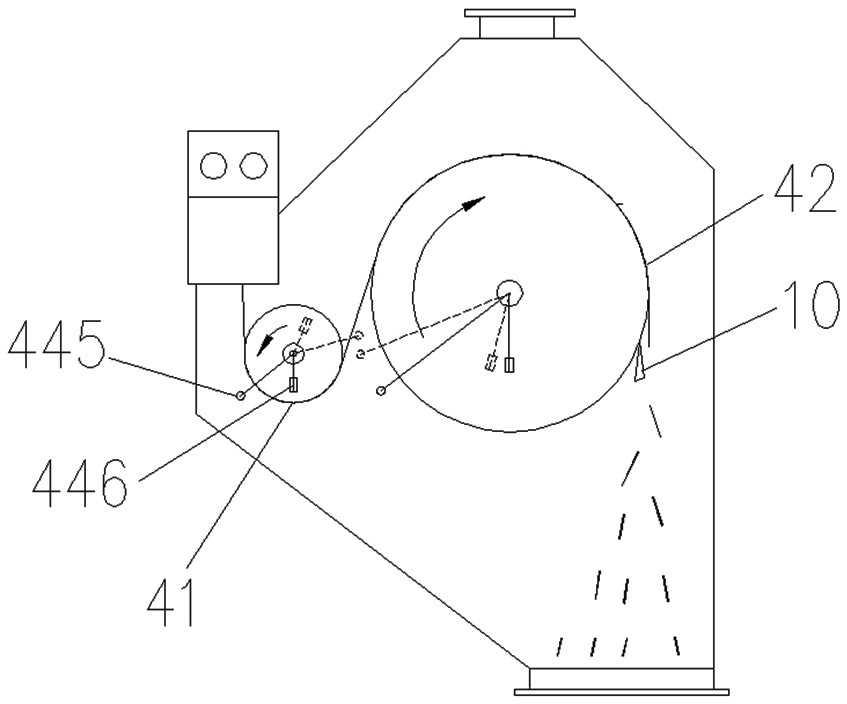

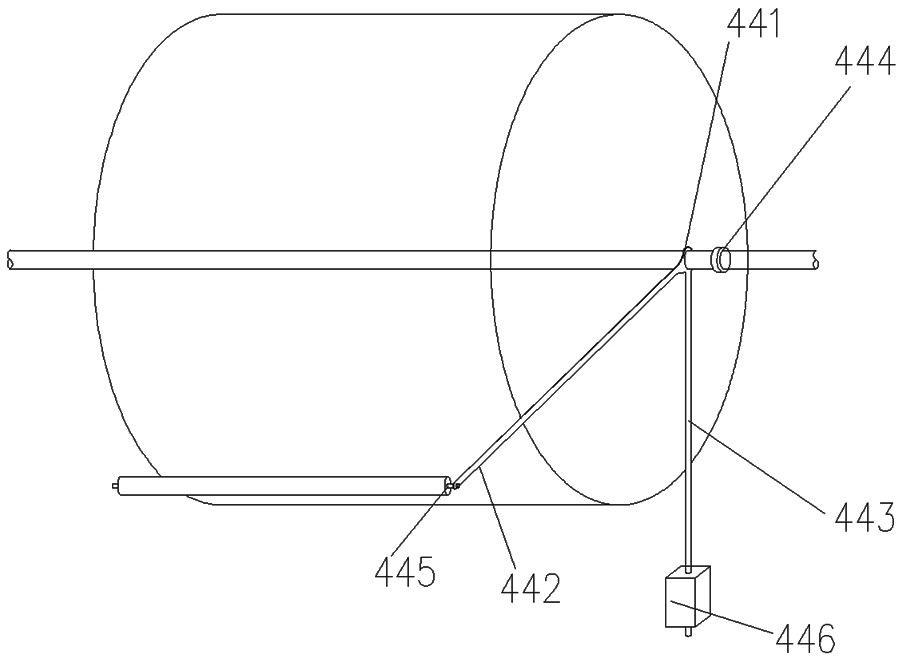

[0061] Step (2): the drying roller 42 in the dryer 4 is fed with steam, the steam temperature is 150-165°C, and the heating temperature is adjustable, which can be determined according to the characteristics of the sludge and the final treatment requirements; after the steam is fed for 30s, the dryer 4. The inner drying roller 42 and the preheating roller 41 start to rotate, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com