Bottom mud pollution blocking particle as well as preparation method and application thereof

A sediment and particle technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of loss of coverage and barrier effect, uneven river channels, pollution, etc., and achieve the elimination of black water Odor and mud problems, good anti-scourability, effect of reducing risk of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

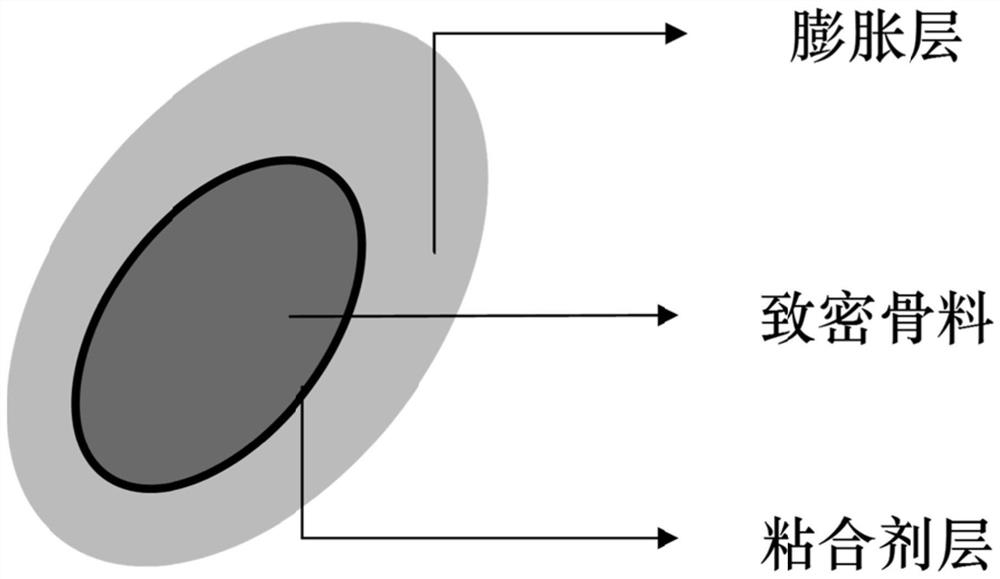

[0074] Preparation of reactive components: the materials of the expansion layer (expansion agent and / or active agent) are stirred at room temperature for 10-20 minutes, and the mixture is uniform;

[0075] Preparation of sediment pollution blocking: the aggregate coated with binder and the uniformly mixed reactive component materials are fully mixed, granulated, dried, and screened to obtain sediment pollution blocking particles.

[0076] The compositions of the sediment pollution blocking particles of different examples and comparative examples are shown in the following table.

[0077]

[0078]

[0079] Note: The preparation method of Comparative Example 1 is to mix aggregate, binder, expansion agent and active agent together, granulate, dry, and sieve to obtain sediment pollution blocking particles; expansion agent is the expansion coefficient unless otherwise specified. It is 20 to 30 times the sodium bentonite.

[0080] Performance Test Example

[0081] The produc...

Embodiment 4

[0103] Examples 4 and 5 select larger gravel with a particle size of 10 to 20 mm, and its specific surface area is smaller than the gravel with a particle size of 3 to 7 mm. Therefore, the proportion of gravel of the products prepared in Examples 4 and 5 reaches 90%. % and 91%, the proportion of bentonite decreased, which led to the decline of the product's sediment pollutant control effect and the decline of the anti-scour performance. In Example 6, pebbles with a particle size of 30-50 mm were selected, and the control effect of the prepared product on sediment pollutants decreased more significantly, and the CMC and bentonite, which accounted for 6% of the product weight, lost only 1%.

Embodiment 7

[0104] Example 7 selects the river sand (0.5~2mm) with the smallest particle size. Because the specific surface area of the aggregate is larger, the bentonite ratio of the prepared product is increased to 18%, and the control effect of the product on the sediment pollutants is the same as that of Example 1. ~3 is close, but the anti-scour performance of the product has declined. Considering the endogenous inhibitory effect, anti-scour performance and product cost of the product, the preferred particle size is 3-7mm gravel: CMC: sodium bentonite: active agent = 86:1.5 :10.5:2 is the preferred formula for the product.

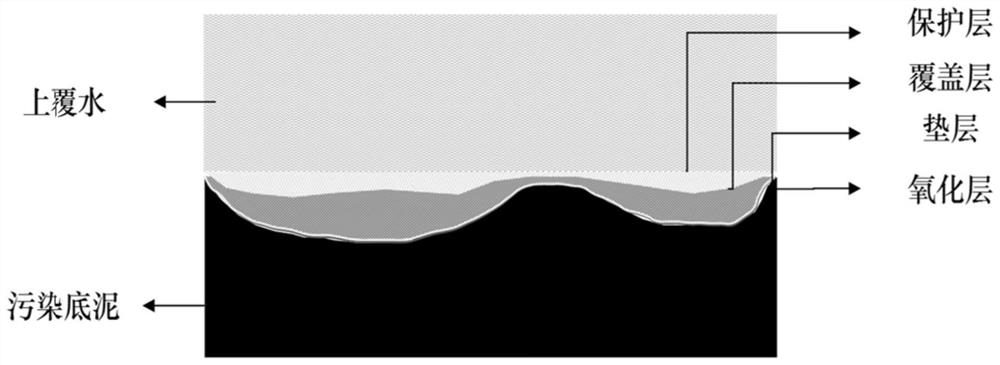

[0105] Comparison of the application effects of different materials covering

[0106] In one example, the application effect of the granular product in Example 1 and the conventional covering material (river sand) was compared.

[0107] The test device is the same as in Test Example 3, and the granular product prepared in Example 1 is placed on the soil surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com