Amorphous refractory metal alloy ablation-resistant coating and preparation method and application thereof

A refractory metal, anti-ablation technology, applied in metal material coating process, coating, vacuum evaporation coating and other directions, can solve the problems of deterioration of mechanical properties of gun steel, insufficient wear resistance of coating, high heating temperature, etc. , to improve the service life of components, improve the anti-ablation effect, and reduce the effect of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a method for preparing an amorphous refractory metal alloy anti-ablation coating, which is prepared by the following methods:

[0035] (1) Target preparation: Cr metal powders are weighed by a certain weight, and a single metal material prepared by vacuum smelting is used as a target for magnetron sputtering, that is, a Cr target; Ta metal powder is weighed according to a certain weight The weight is weighed, and the single metal material prepared by the powder metallurgy method is used as the target material of magnetron sputtering, that is, the Ta target material.

[0036] (2) Substrate pretreatment: take gun steel PCrNi3MoVA as the substrate, and use #240, #600, #1000, #1500, #2000 sandpaper to polish and polish the surface of the substrate, and then use acetone, alcohol and deionized water respectively. Ultrasonic cleaning, blow dry.

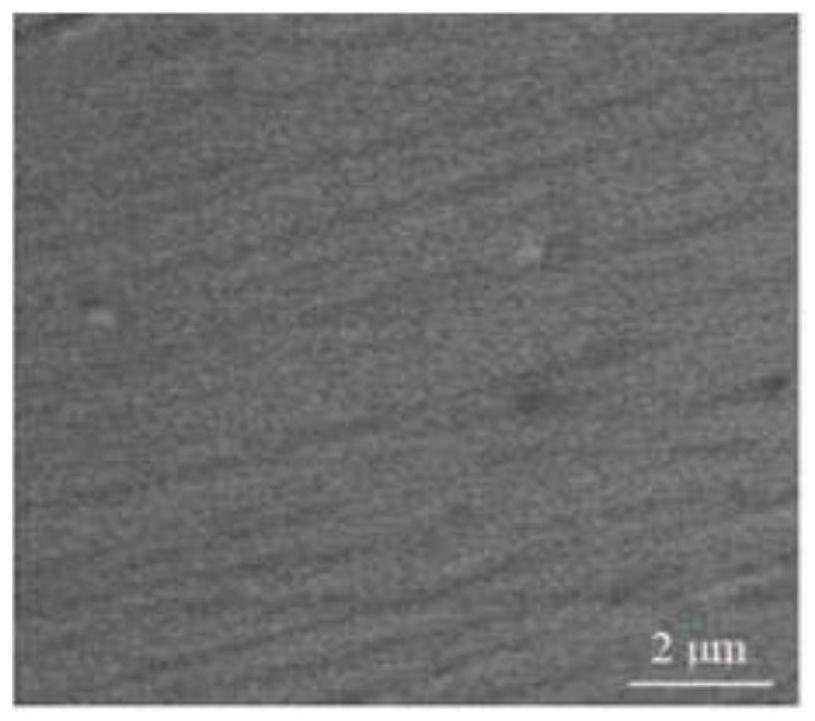

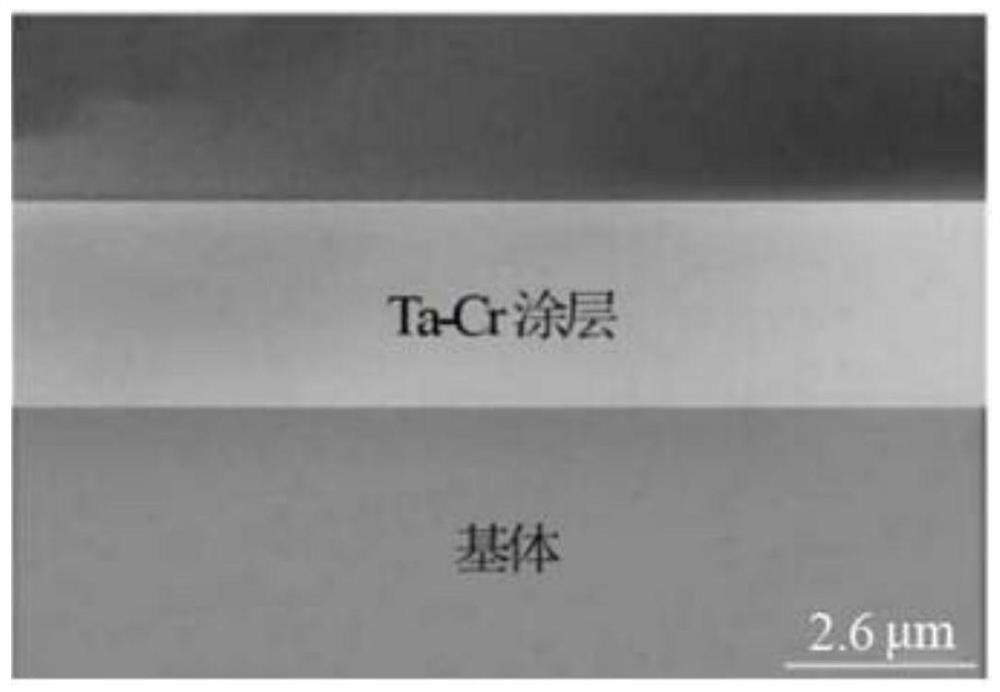

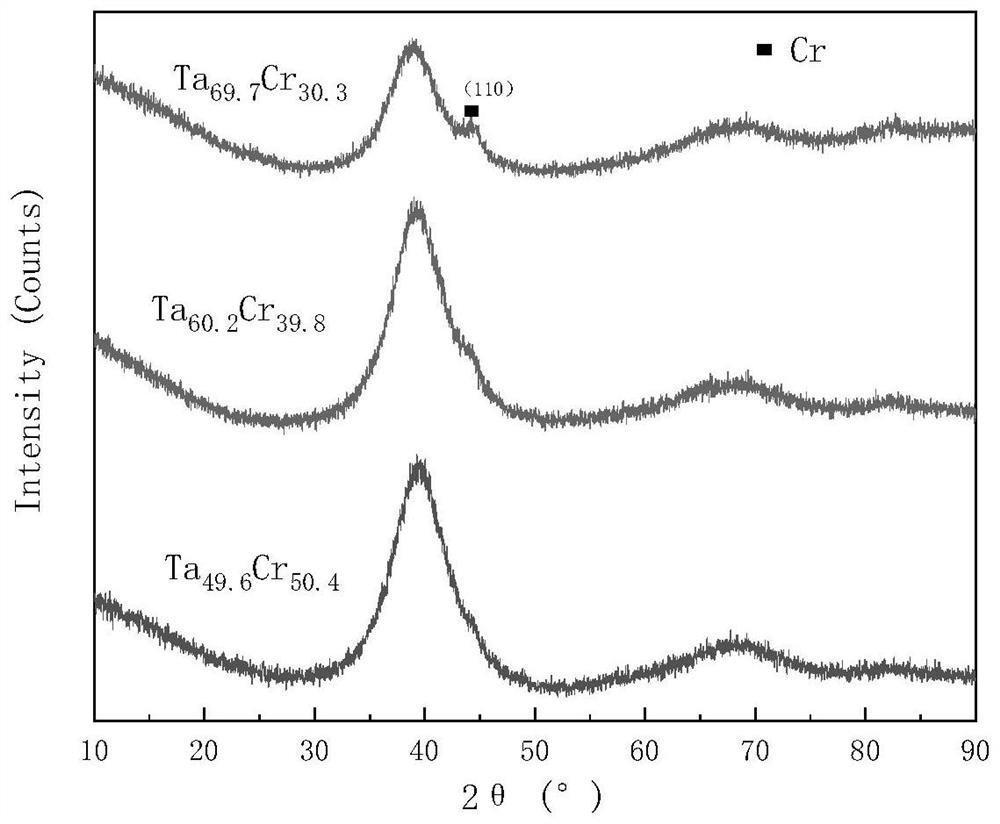

[0037] (3) Deposition of anti-ablation coating of amorphous refractory metal alloy: magnetron sputt...

Embodiment 2

[0039] This embodiment provides a method for preparing an amorphous refractory metal alloy anti-ablation coating, which is different from Embodiment 1 only in that in step (3), the process parameters for coating deposition are: background vacuum degree 3×10 -3 Pa, the substrate temperature is 350°C, the Cr target uses a DC power supply with a power of 40W, the Ta target uses a radio frequency power supply with a power of 100W, the substrate DC bias voltage is -80V, the target-base distance is 6cm, the working pressure is 0.3Pa, and the argon flow rate is 20sccm, by controlling the sputtering time to 4h to achieve a thickness of about 3μm, the anti-ablation coating Ta containing amorphous refractory metal alloy is obtained 41.7 Cr 58.3 (the lower corner is the atomic percent of the element) material.

Embodiment 3

[0041] The present embodiment provides a method for preparing an amorphous refractory metal alloy anti-ablation coating, which differs from Embodiment 1 only in that:

[0042] In step (3), the process parameters of coating deposition are: background vacuum degree 1×10 -3 Pa, the substrate temperature is 350°C, the Cr target uses a DC power supply with a power of 20W, the Ta target uses a radio frequency power supply with a power of 90W, the substrate DC bias voltage is -80V, the target-base distance is 6cm, the working pressure is 0.3Pa, and the argon flow rate is 20sccm, by controlling the sputtering time to 6h to achieve a thickness of about 4.5μm, to obtain an anti-ablation coating containing amorphous refractory metal alloy Ta 75 Cr 25 (the lower corner is the atomic percent of the element) material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com