Modified carbon fiber as well as preparation method and application thereof

A technology of carbon fiber and modified carbon, which is applied in the direction of carbon fiber, fiber treatment, ultrasonic/sonic fiber treatment, etc., and can solve the problem of low interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

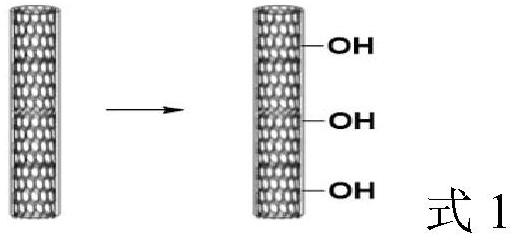

[0036] (1) The carbon fiber is treated with plasma to form hydroxyl groups on the surface of the carbon fiber;

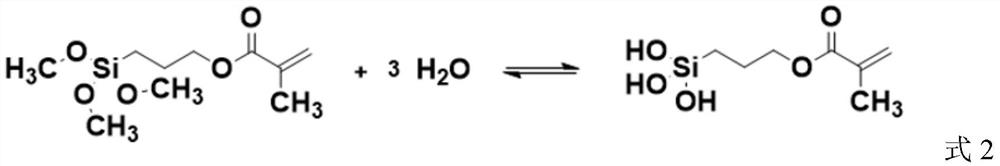

[0037] (2) Mix methanol and water with a mass ratio of 1:1 to obtain a mixed system, then adjust the pH of the system to 3 with acetic acid, put the configured mixed system into a three-necked flask, and add dropwise with stirring the mass fraction of 0.5% methacryloyloxypropyltrimethoxysilane (MPS) was hydrolyzed at 25° C. for 30 minutes to obtain a hydroxyl-rich silane aqueous solution with a large degree of hydrolysis and a small degree of polycondensation.

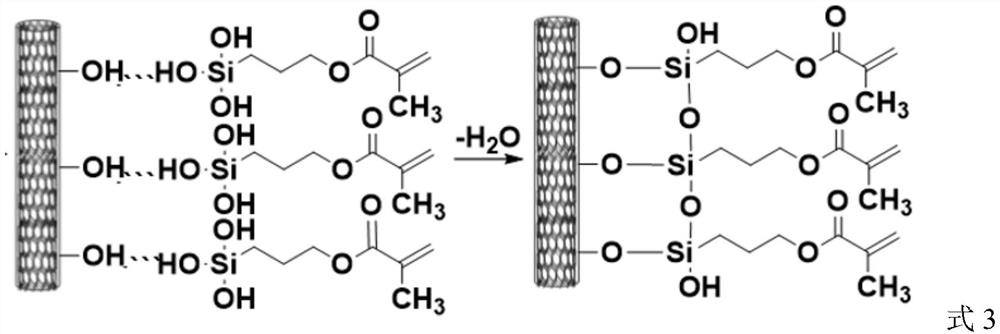

[0038](3) adding the carbon fiber after the plasma treatment obtained in step (1) to the hydroxyl-rich silane aqueous solution obtained in step (2), setting the temperature of the oscillating water bath to 50° C., reacting for 20 min, and then alternately cleaning excess water with methanol and water Siloxane to obtain secondary functionalized carbon fibers.

[0039] (4) heating the secondary functionalized...

Embodiment 2

[0042] (1) The carbon fiber is treated with plasma to form hydroxyl groups on the surface of the carbon fiber;

[0043] (2) Mix methanol and water according to the mass ratio of 20:1 to obtain a mixed system, then adjust the pH of the system to 3 with acetic acid, place the configured mixed system in a shaking water bath, and add the mass fraction dropwise with stirring It is 5% methacryloyloxypropyltrimethoxysilane (MPS), hydrolyzed at 40° C. for 3 h to obtain a hydroxyl-rich silane aqueous solution.

[0044] (3) adding the plasma-treated carbon fiber obtained in step (1) to the hydroxyl-rich silane aqueous solution obtained in step (2), reacting for 20 min, and then alternately washing excess siloxane with methanol and water to obtain secondary functionalization of carbon fiber.

[0045] (4) heating the secondary functionalized carbon fiber at 150° C. for 5 min to complete the polycondensation of siloxane on the secondary functionalized carbon fiber and remove the water and...

Embodiment 3

[0048] (1) Anodizing the carbon fibers with ammonium bicarbonate as the electrolyte solution to form hydroxyl groups on the surface of the carbon fibers;

[0049] (2) Mix ethanol and water in a mass ratio of 10:1 to obtain a mixed system, then adjust the pH of the system to 3 with acetic acid, put the configured mixed system into a three-necked bottle, and add dropwise with stirring the mass fraction of 2% aminopropyltriethoxysilane (APTES) was hydrolyzed at 25° C. for 3 h to obtain a hydroxyl-rich silane aqueous solution.

[0050] (3) adding the carbon fiber after the plasma treatment obtained in step (1) to the hydroxyl-rich silane aqueous solution obtained in step (2), setting the temperature of the oscillating water bath to be 50° C., reacting for 20 min, and then alternately cleaning excess water with ethanol and water Siloxane to obtain secondary functionalized carbon fibers.

[0051] (4) heating the secondary functionalized carbon fiber at 100° C. for 40 min to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com