Method for reducing equivalent series resistance of laminated capacitor

A technology of equivalent series resistance and stacked capacitors, which is applied in the field of capacitors, can solve problems such as inability to break through, low ESR value, cumbersome steps, etc., and achieve the effects of improving capacity and leakage current pass rate, reducing ESR, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

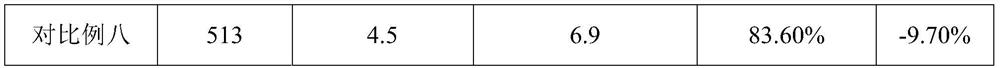

Examples

Embodiment 1

[0035]A method for reducing the equivalent series resistance of a multilayer capacitor, comprising: firstly impregnating a monomer solution at a low temperature, and then impregnating an oxidizing solution at a low temperature, then removing the foil from the oxidizing solution and blowing off excess excess on the sides of the foil with a high-pressure air curtain For the oxidation solution, the above steps are one cycle; after one cycle is performed, the monomer solution is impregnated once and dried.

[0036] Among them, the weight percentage of each component of the monomer solution is: monomer pyrrole 9.5wt%, solvent water 85wt%, dopant sodium polystyrene sulfonate 5wt%, auxiliary γ-mercaptopropyl triethoxysilane 0.1 wt% with fluorinated acrylic copolymer 0.4 wt%.

[0037] The temperature at which the monomer solution was impregnated was 1°C, and the time for which the monomer solution was impregnated was 95 seconds.

[0038] The weight percentage of each component of the...

Embodiment 2

[0045] A method for reducing the equivalent series resistance of a multilayer capacitor, comprising: firstly impregnating a monomer solution at a low temperature, and then impregnating an oxidizing solution at a low temperature, then removing the foil from the oxidizing solution and blowing off excess excess on the sides of the foil with a high-pressure air curtain The oxidation solution, the above steps are one cycle; after 6 cycles, the monomer solution is impregnated once and dried.

[0046] Among them, the weight percentage of each component of the monomer solution is: monomer 3,4-ethylenedioxythiophene 5.5wt%, solvent ethanol 90wt%, dopant polyvinylsulfonic acid 2.75wt%, auxiliary γ-mercaptopropyl 1 wt % of triethoxysilane and 0.75 wt % of fluorinated acrylic copolymer.

[0047] The temperature at which the monomer solution was impregnated was 4°C, and the time for which the monomer solution was impregnated was 50 seconds.

[0048] The weight percentage of each component...

Embodiment 3

[0055] A method for reducing the equivalent series resistance of a multilayer capacitor, comprising: firstly impregnating a monomer solution at a low temperature, and then impregnating an oxidizing solution at a low temperature, then removing the foil from the oxidizing solution and blowing off excess excess on the sides of the foil with a high-pressure air curtain For the oxidation solution, the above steps are one cycle; after 11 cycles, the monomer solution is impregnated once and dried.

[0056] Among them, the weight percentage of each component of the monomer solution is: monomer aniline 1.5wt%, solvent water 70wt% and ethanol 25wt%, dopant m-sulfobenzamide 0.5wt%, auxiliary γ-mercaptopropyl tris Ethoxysilane 1wt% and potassium dodecyl sulfate 2wt%.

[0057] The temperature at which the monomer solution was impregnated was 6° C., and the time for which the monomer solution was impregnated was 5 seconds.

[0058] The weight percentage of each component of the oxidation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com