Preparation method and application of boron-nitrogen modified metal electrocatalyst for improving oxygen reduction durability

An electrocatalyst and durability technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems affecting the electrocatalytic activity of metals and the conductivity of precious metals, and achieve good performance and long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

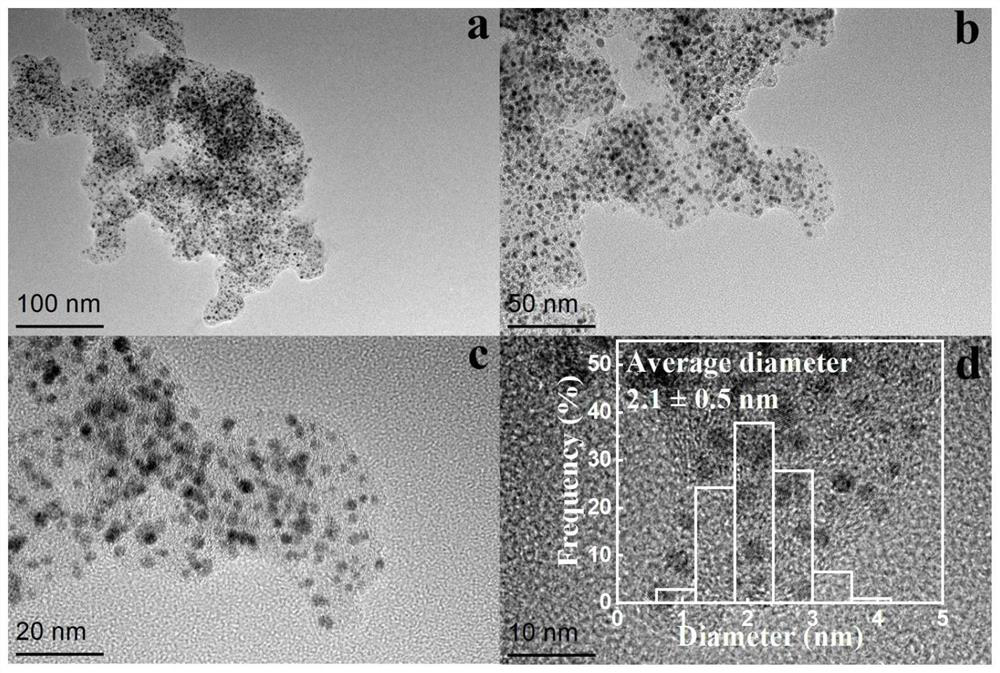

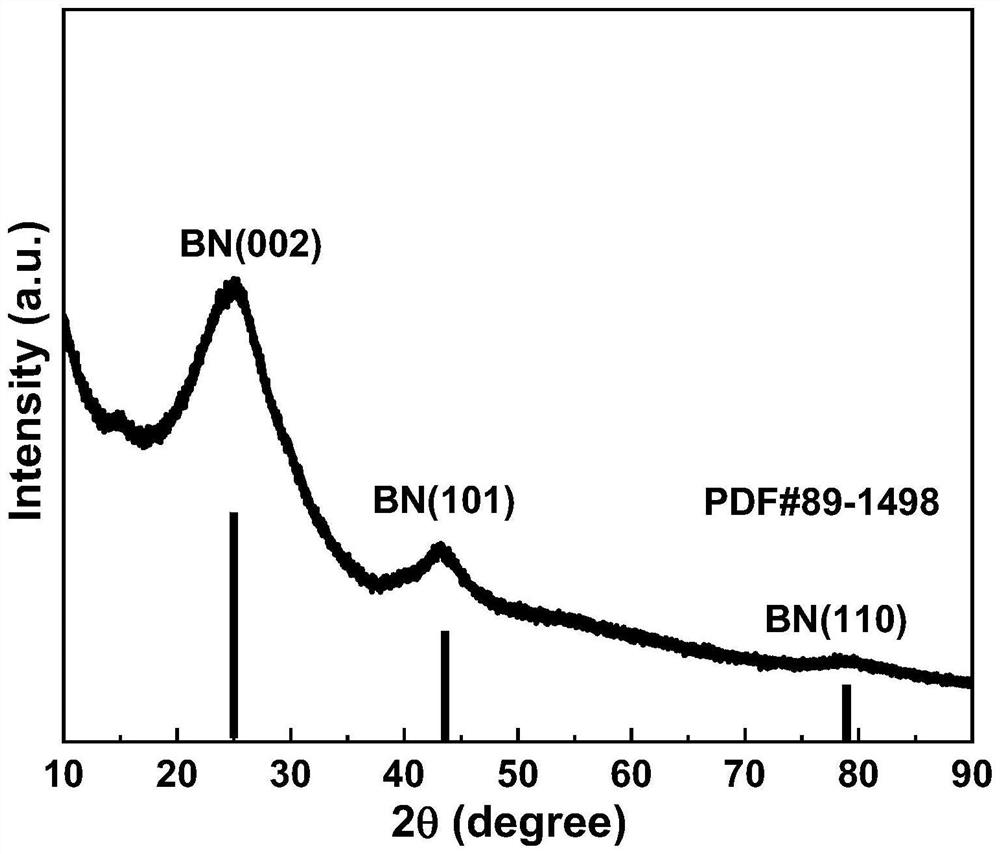

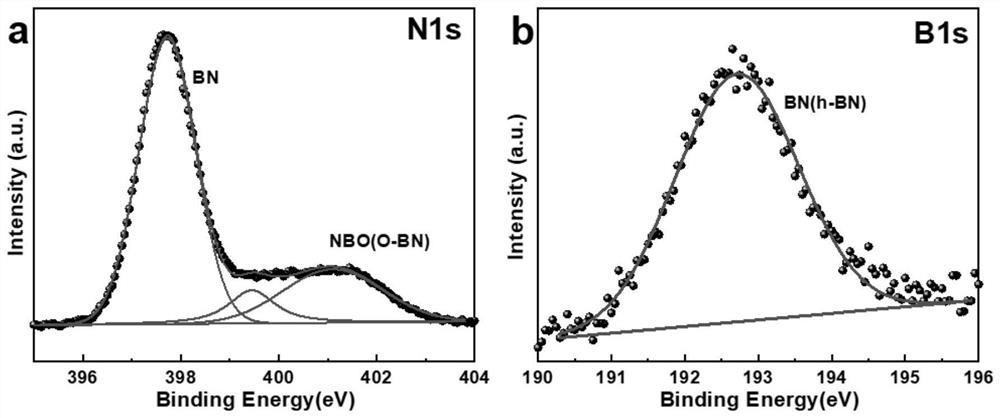

Image

Examples

Embodiment 1

[0036] 1) Take 50 mg of a precious metal electrocatalyst (37 wt% commercial platinum carbon, manufacturer: Johnson Matthey), add 100 mL of deionized water, and stir to obtain a black slurry.

[0037] 2) Add 25mg of NH 3 -BH 3 (CAS number: 13774-81-7, Aladdin) in the solution, let stand for 12h, when the bubbles disappear completely, ultrasonicate for 15min, place it in a constant temperature water bath at 60°C for 12h with magnetic stirring, and then place it in a blast drying oven for 60 Dry at ℃ for 12h to obtain a mixture of white powder and black powder.

[0038] 3) The mixture is carbonized in a tube furnace with argon. The carbonization program is: from room temperature to 500 °C at a heating rate of 5 °C / min, holding for 2 hours, then cooling to room temperature with the furnace, taking out, using agate Grinding in a mortar for 1 min, no washing, no drying, recorded as BN-PtM / C-2 (m is PtM / C and NH 3 -BH 3 mass ratio).

Embodiment 2

[0041] 1) Take 50 mg of a precious metal electrocatalyst (37 wt% commercial platinum carbon, manufacturer: Johnson Matthey), add 100 mL of deionized water, and stir to obtain a black slurry.

[0042] 2) Add 50mg of NH 3 -BH 3 (CAS number: 13774-81-7, Aladdin) in the solution, let stand for 12h, when the bubbles disappear completely, ultrasonicate for 15min, place it in a constant temperature water bath at 60°C for 12h with magnetic stirring, and then place it in a blast drying oven for 60 Dry at ℃ for 12h to obtain a mixture of white powder and black powder.

[0043] 3) The mixture is carbonized in a tube furnace with argon. The carbonization program is: from room temperature to 500 °C at a heating rate of 5 °C / min, holding for 2 hours, then cooling to room temperature with the furnace, taking out, using agate Grind in a mortar for 1 min without washing or drying, denoted as BN-PtM / C-1.

Embodiment 3

[0045] 1) Take 50 mg of a precious metal electrocatalyst (37 wt% commercial platinum carbon, manufacturer: Johnson Matthey), add 100 mL of deionized water, and stir to obtain a black slurry.

[0046] 2) Add 75mg of NH 3 -BH 3 (CAS number: 13774-81-7, Aladdin) in the solution, let stand for 12h, when the bubbles disappear completely, ultrasonicate for 15min, place it in a constant temperature water bath at 60°C for 12h with magnetic stirring, and then place it in a blast drying oven for 60 Dry at ℃ for 12h to obtain a mixture of white powder and black powder.

[0047] 3) The mixture is carbonized in a tube furnace with argon. The carbonization program is: from room temperature to 500 °C at a heating rate of 5 °C / min, holding for 2 hours, then cooling to room temperature with the furnace, taking out, using agate Grind in a mortar for 1 min without washing or drying, denoted as BN-PtM / C-2 / 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com