Method for extracting dandelion anti-inflammatory component by ultrasonic-assisted deep-eutectic solvent method

A low eutectic solvent, ultrasonic-assisted technology, used in separation methods, solvent extraction, solid solvent extraction and other directions, can solve the problems of inability to store for a long time, the extract is easily contaminated, and the yield of active ingredients is difficult to guarantee. The effect of high rate and optimized process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

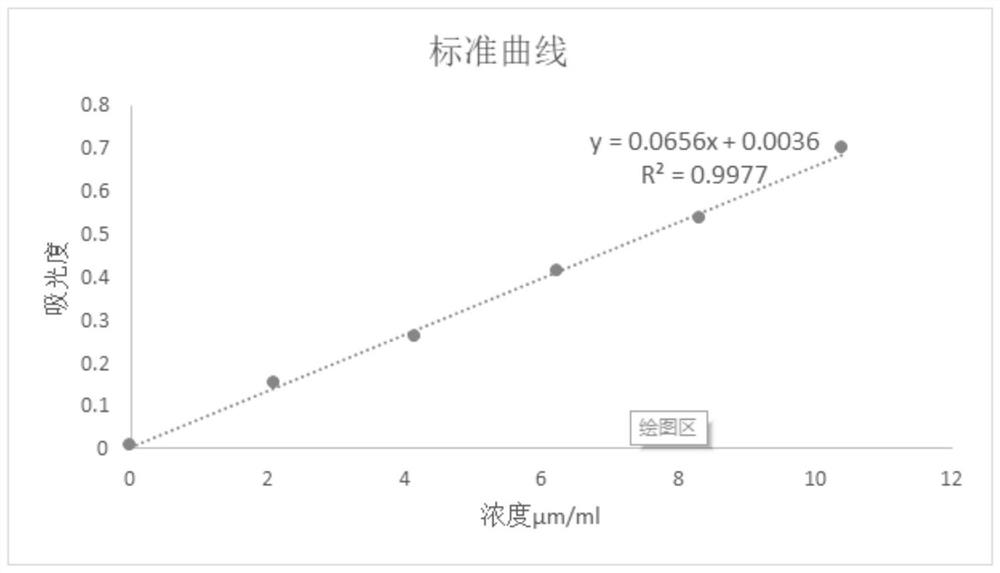

[0035] Example 1: Standard curve drawing

[0036] (1) Weigh 0.0208 g of quercetin standard, dilute to a 100 mL volumetric flask with ethanol, and prepare a solution of 208 μg / mL.

[0037] (2) Take 0, 0.5, 1, 1.5, 2, and 2.5 mL of the control solution and place them in a 50 mL quantitative bottle; and dilute to 50 mL with ethanol to prepare 0 μg / mL, 2.08 μg / mL, 4.16 μg / mL, 6.24μg / mL, 8.32μg / mL, 10.4μg / mL solutions;

[0038] (3) Measure the absorbance at the wavelength of 374 nm (at the maximum absorbance value). Take μg / mL as the abscissa and absorbance as the ordinate to establish a standard curve, and obtain the linear regression equation y=0.0656x+0.0036, R 2 = 0.9977, see figure 1 .

Embodiment 2

[0039] Embodiment 2: The optimization method of the process condition of ultrasonic-assisted deep eutectic solvent extraction of anti-inflammatory components of dandelion, the specific steps are as follows

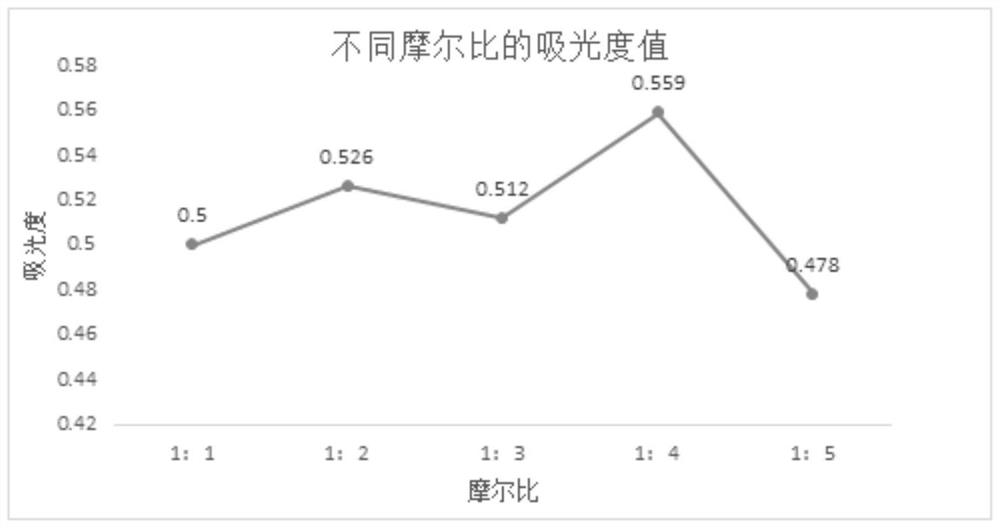

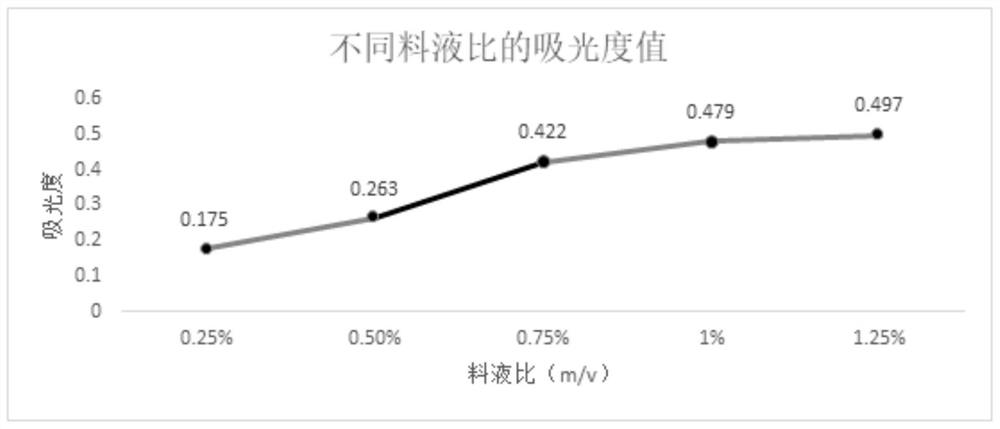

[0040] 2.1 Determination of deep eutectic solvent (DESs) combinations

[0041] The best combination was selected from choline chloride-lactic acid, choline chloride-fructose, choline chloride-ethylene glycol, choline chloride-glycerol, choline chloride-urea, and choline chloride-urea was selected first. : Hydrogen donor = 1:2 molar ratio, put into 50 mL of reagent, place it in an oil bath at 90°C for 1 hour with stirring to ensure that the deep eutectic solvent is clear and transparent, then cut 40 mL into a centrifuge tube, add 10 mL of Ultrapure water and 0.5g of dandelion powder passed through a 40-mesh sieve were prepared into a 50mL solution with a water content of 20%, a solid-liquid ratio of 1%, and a molar ratio of 1:2, and ultrasonicated for 90 minutes in an ultra...

Embodiment 3

[0066] Example 3: Macroporous resin purification of dandelion extract

[0067] The resin column was first plugged with absorbent cotton, and 10 g of the treated dry resin was diluted with 20 mL of water to form a resin aqueous solution and poured into the resin column. After the resin is completely precipitated, add 50 mL of the extract sample solution of the deep eutectic solvent, pass through the resin column at a flow rate of 5 BV / h, do this twice, and then use 200 mL of distilled water to pass through the resin column at a flow rate of 10 BV / h until the flow rate is 10 BV / h. The solution was colorless, thereby removing the deep eutectic solvent remaining in the resin, and finally desorbing the macroporous adsorption resin with about 200 mL of 95% ethanol solution at a flow rate of 10 BV / h until the effluent solution was colorless. The desorbed solution of the 95% ethanol solution was collected and subjected to rotary evaporation to obtain the dandelion solid extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com