Aerobic tank floating filler as well as preparation method and application thereof

A technology of floating packing and aerobic pool, which is applied in chemical instruments and methods, control of water treatment parameters, water/sludge/sewage treatment, etc. It can solve problems such as uneven mixing, low treatment efficiency, and low oxygen utilization rate. Achieve the effect of improving treatment efficiency and treatment effect, high economic benefit and environmental effect, and improving oxygen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

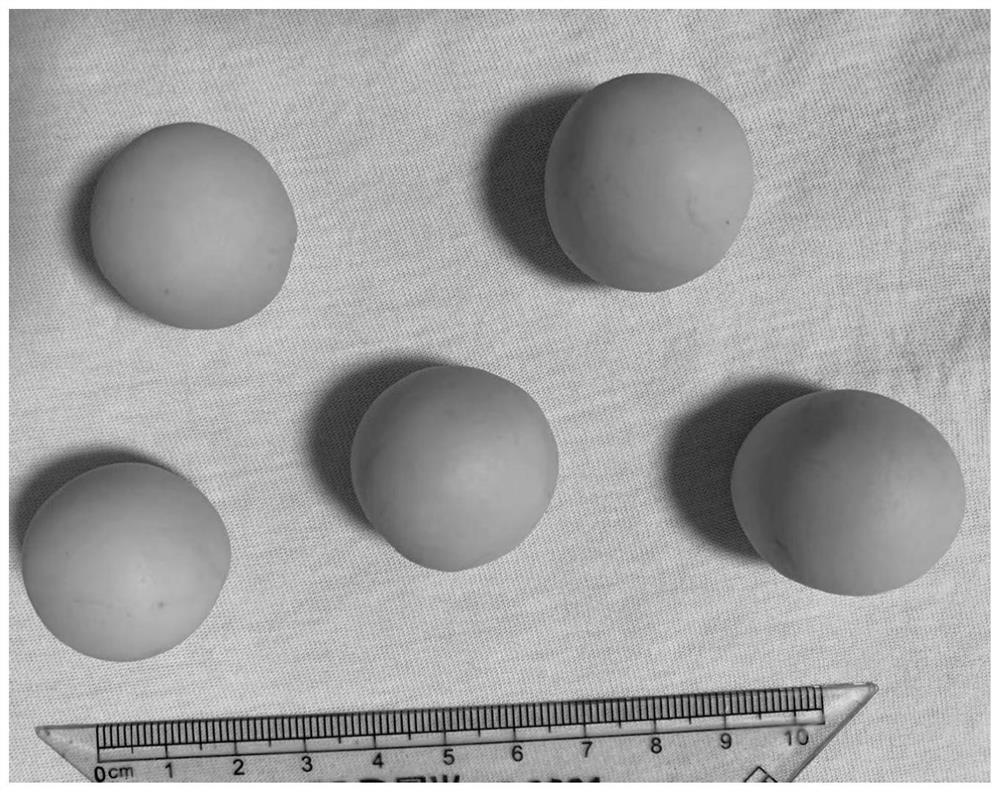

[0033] In order to obtain the floating filler with uniform particle size and good sphericity, the embodiment of the present application also provides a preparation method of the floating filler, including the following steps:

[0034] Step a, weigh each component according to the designed ratio, add the weighed components into the reaction kettle and mix evenly, react at 65°C to 70°C for 2h to 2.5h to obtain an emulsion; in the reaction kettle at 65°C Under the condition of ~70°C, each material forms a eutectic, and styrene and divinylbenzene react to form a styrene resin;

[0035] Step b, discharging the emulsion into an aqueous gelatin solution for molding, vacuum extracting a pore-forming agent and an aqueous gelatin solution, and drying to obtain the floating filler in the aerobic tank; discharging the emulsion obtained by the reaction into an aqueous gelatin solution After that, spherical floating beads are formed, and the diameter of the floating filler can be controlled...

Embodiment 1

[0038] The embodiment of the present invention provides an aerobic tank flotation filler, comprising the following components by mass percentage:

[0039] A floating filler for an aerobic pool, which is a spherical porous structure, and includes the following components by mass percentage: 0.1% of float beads, 3% of polypropylene, 1.5% of aluminum oxide, 2% of xylene, and the balance of benzene Vinyl resin monomer;

[0040] Wherein, the styrene-based resin monomer is styrene and divinylbenzene with a mass ratio of 67:33; the particle diameters of the floating beads and aluminum oxide are less than 500 mesh.

[0041]The preparation method of the above-mentioned aerobic tank floating filler, specifically comprises the following steps:

[0042] In step a, the float beads and the aluminum oxide are respectively ground, and sieved through a 500-mesh sieve for use.

[0043] In step b, each component is weighed according to the designed ratio, and the weighed component is added to ...

Embodiment 2

[0046] The embodiment of the present invention provides an aerobic tank flotation filler, comprising the following components by mass percentage:

[0047] A floating filler for an aerobic pool, which is a spherical porous structure, and comprises the following components by mass percentage: 0.3% of float beads, 2% of polypropylene, 1% of aluminum oxide, 1.5% of xylene, and the balance is benzene Vinyl resin monomer;

[0048] Wherein, the styrene-based resin monomer is styrene and divinylbenzene with a mass ratio of 69:31; the particle diameters of the floating beads and aluminum oxide are less than 500 mesh.

[0049] The preparation method of the above-mentioned aerobic tank floating filler, specifically comprises the following steps:

[0050] In step a, the float beads and the aluminum oxide are respectively ground, and sieved through a 500-mesh sieve for use.

[0051] In step b, each component is weighed according to the designed ratio, and the weighed component is added t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com