A Laser Array Coupling System with Beam Correction

A laser array and coupling system technology, applied in the field of laser array coupling systems, can solve the problems of residual divergence angle, space waste, large spot size, etc., and achieve the effects of eliminating residual divergence angle, reducing complexity and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

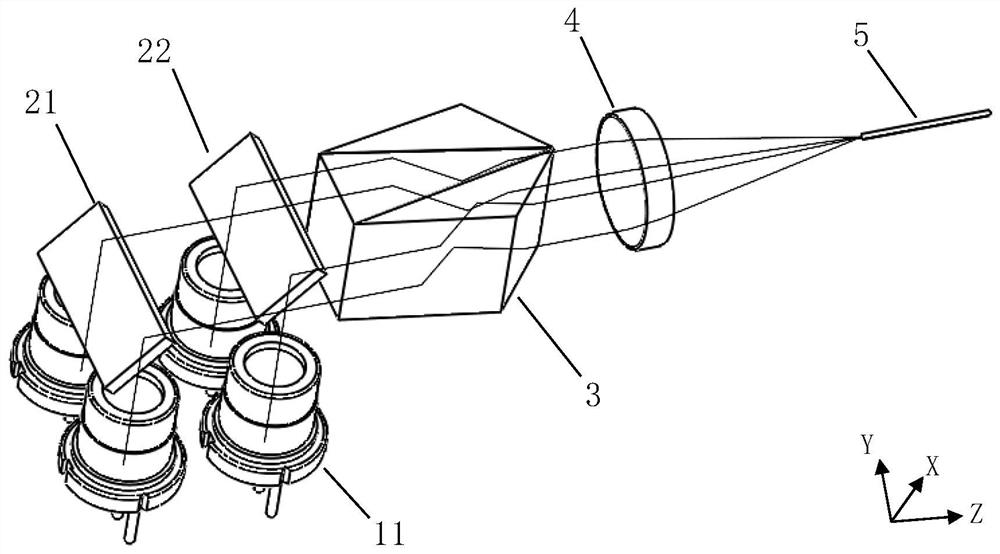

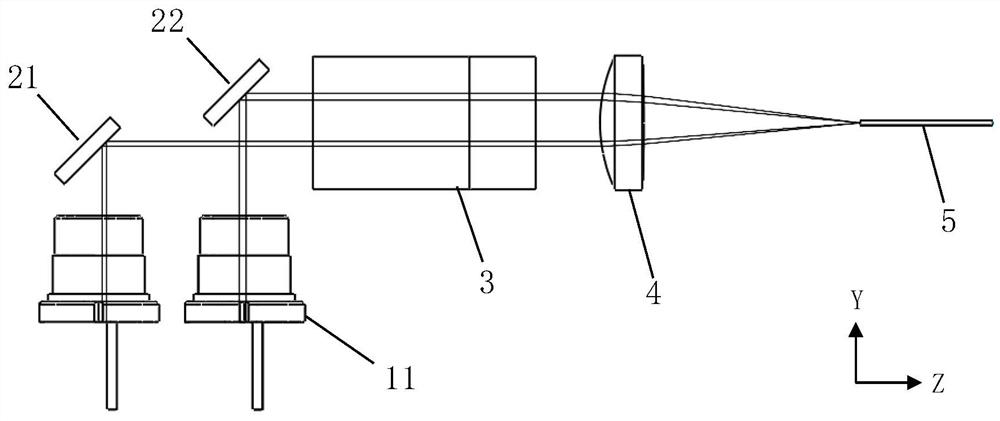

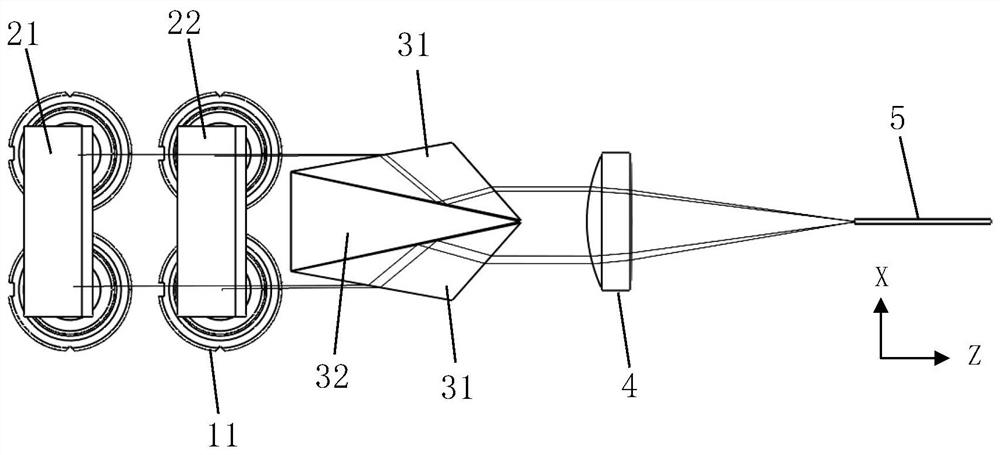

[0055] like Figure 1-3 As shown, this embodiment discloses a laser array coupling system with beam correction, the laser array coupling system with beam correction includes a laser light source, a fast axis adjustment unit, a beam correction composite prism 3, a convergence unit 4 and a single core Fiber 5.

[0056] The laser light source is used for emitting a laser beam array, and the laser light source includes a first group of laser diodes and a second group of laser diodes; wherein the first group of laser diodes and the second group of laser diodes each include at least two laser diodes 11 . refer to image 3 , in this embodiment, both the first group of laser diodes and the second group of laser diodes include two laser diodes 11 , the upper two laser diodes 11 constitute the first group of laser diodes, and the lower two laser diodes 11 constitute the second group of laser diodes diode.

[0057] refer to Figure 4 , the collimated beam output by the laser diode 11...

Embodiment 2

[0066] like Figure 7-8 As shown, the difference between the laser array coupling system with beam correction in this embodiment and the first embodiment is that the transmission direction of the laser beams emitted by the two adjacent laser diodes 11 (above) in the X direction is the Z direction, and the X direction is the same as the one in the X direction. The transmission direction of the laser beams emitted by the adjacent two laser diodes 11 (below) is the Y direction. The fast axis adjustment unit 2 in this embodiment includes a third mirror 23, which is used to phase the X direction. The laser beams emitted by the two adjacent laser diodes 11 (below) are reflected to the beam correction composite prism 3, and the laser beams emitted by the two adjacent laser diodes 11 (above) in the X direction are directly incident on the beam correction composite prism 3, refer to Figure 7 , which also reduces the spacing between adjacent laser beams in the fast axis direction.

Embodiment 3

[0068] like Figure 9-10 As shown, the difference between the laser array coupling system with beam correction in this embodiment and the first embodiment is that the transmission directions of the laser beams emitted by the four laser diodes are all in the Z direction, and the fast axis adjustment unit 2 in this embodiment includes A parallelogram reflecting prism 24, the third reflecting mirror 23 is used to reflect twice the laser beams emitted by the two laser diodes 11 (below) adjacent in the X direction, and then incident on the beam correction composite prism 3, adjacent in the X direction The laser beams emitted by the two laser diodes 11 (above) are directly incident on the beam correction composite prism 3, refer to Figure 9 , which also reduces the spacing between adjacent laser beams in the fast axis direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com