High-nickel cobalt-free lithium ion battery material and preparation method thereof

A lithium-ion battery, high-nickel technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low stability, and achieve the effects of improving stability, improving charging and discharging stability, and inhibiting the dissolution of manganese

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a high-nickel cobalt-free lithium-ion battery material, comprising the following steps:

[0037] 1) adding lithium source, nickel source, R source, zirconium source, manganese source and citric acid to water to obtain a first solution;

[0038] 2) adding ethanol solution to the first solution to obtain a second solution, stirring to obtain a gel;

[0039] 3) drying the gel obtained in step 2) and then calcining to obtain a high-nickel cobalt-free lithium ion battery material.

[0040] In the present invention, the lithium source is one or more of lithium nitrate, lithium acetate, lithium carbonate, lithium formate and lithium citrate;

[0041] Described nickel source is one or both in nickel nitrate and nickel acetate;

[0042] The R source is one or more of aluminum nitrate, aluminum acetate, aluminum oxalate, rare earth metal nitrate and rare earth metal acetate;

[0043] The zirconium source is one or both...

Embodiment 1

[0054] Weigh 0.2mol lithium nitrate, 0.1mol nickel nitrate, 0.05mol aluminum nitrate, 0.02mol zirconium phosphate, 0.03mol manganese nitrate, add them to 1L deionized water, then add 0.50mol citric acid, stir evenly, and then add mass fraction It was 48ml of 60% ethanol solution, stirred at 75°C for 2h to obtain gel;

[0055] The obtained gel was dried at 160 °C for 2 h, and then calcined at high temperature at 780 °C for 1.5 h to prepare Li(Ni 0.5 Al 0.25 Zr 0.1 Mn 0.15 )O 2 Lithium-ion battery material, denoted as LN 0.5 A 0.25 Z 0.1 M 0.15 O 2 .

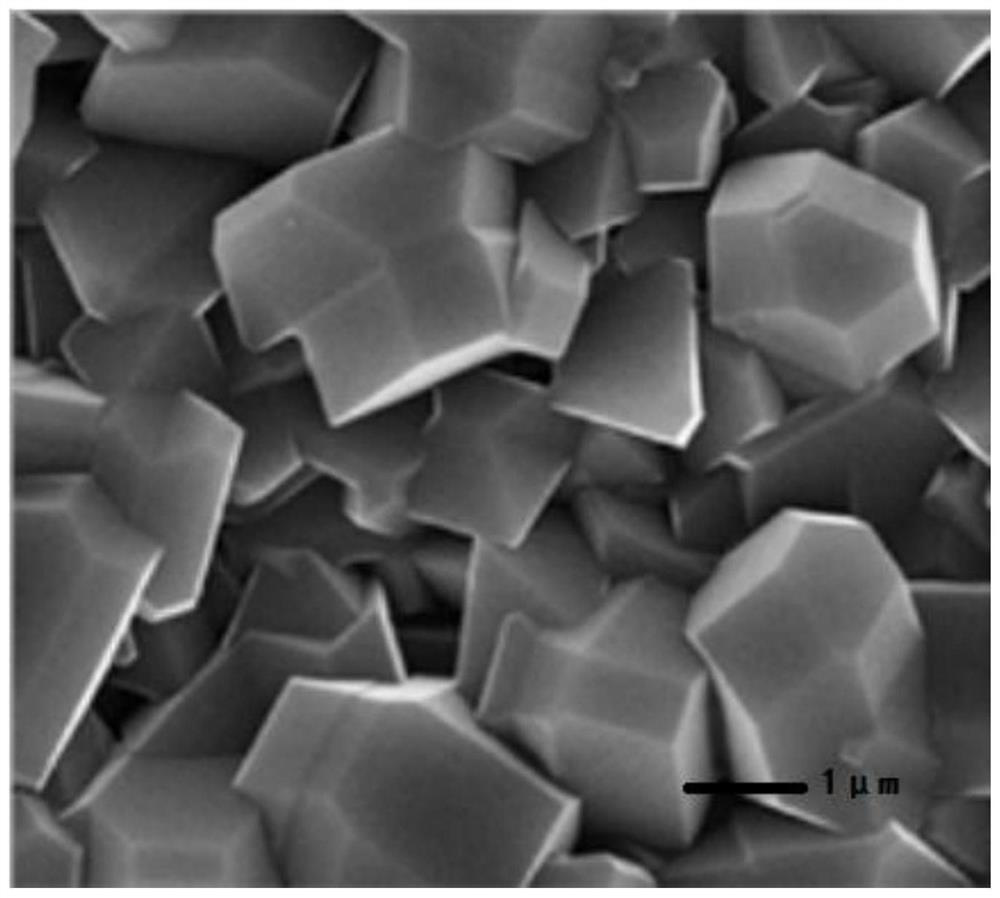

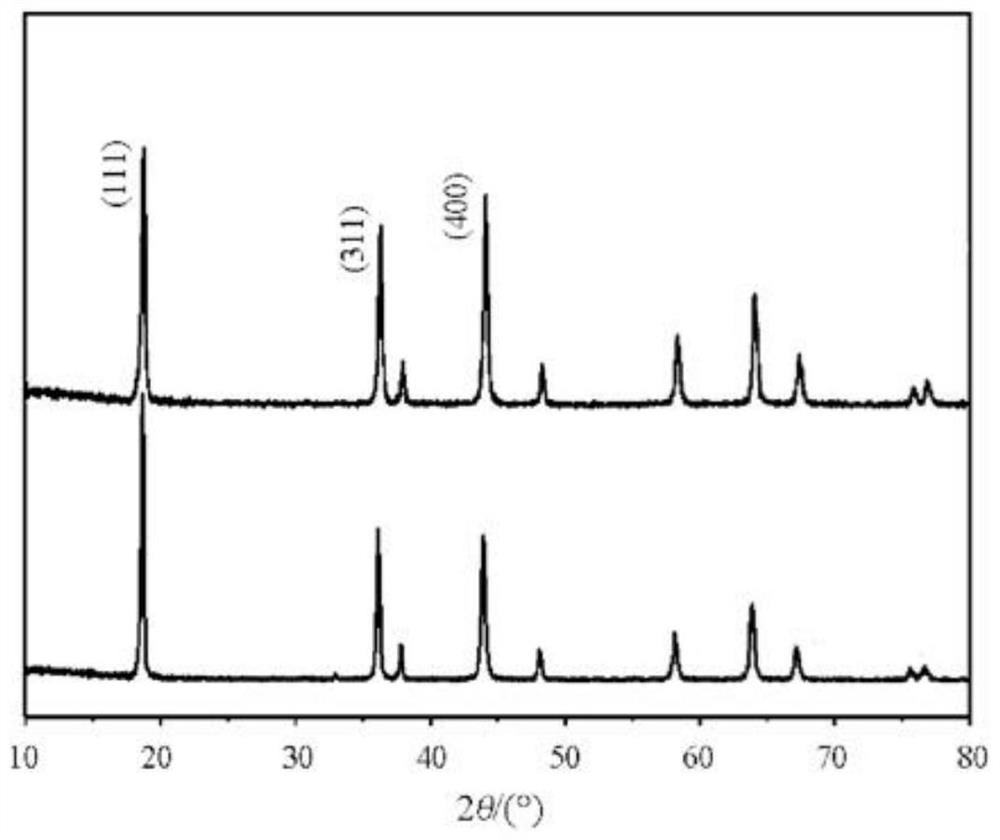

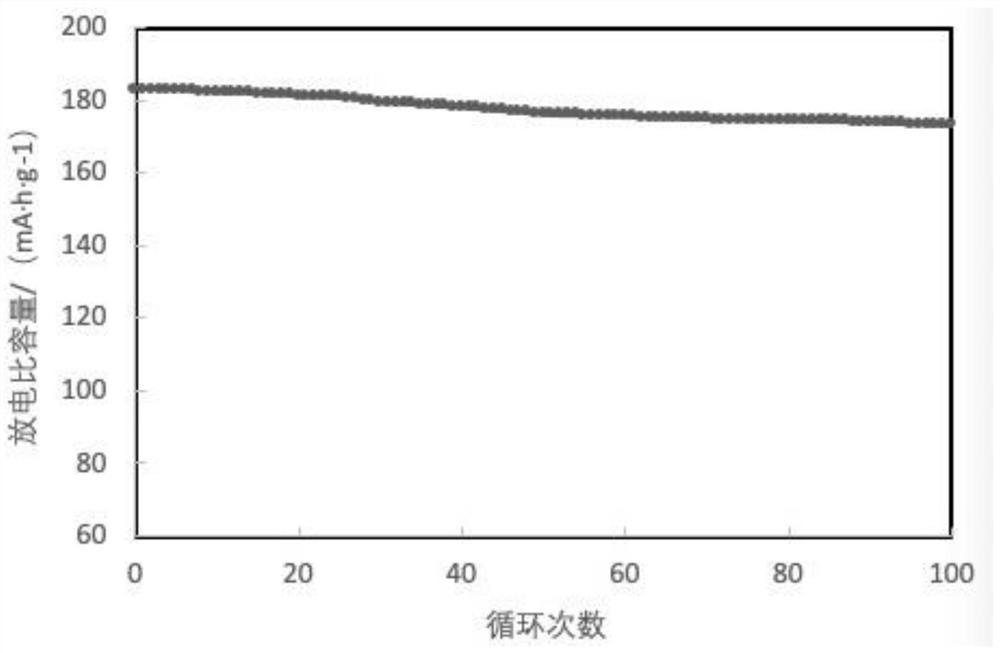

[0056] LN prepared in this example 0.5 A 0.25 Z 0.1 M 0.15 O 2 SEM images of lithium-ion battery materials such as figure 1 shown, LN 0.5 A 0.25 Z 0.1 M 0.15 O 2 Lithium-ion battery materials and LiMn 2 O 4 The XRD pattern of the battery material is as figure 2 As shown, it can be seen that the LN prepared by the present invention 0.5 A 0.25 Z 0.1 M 0.15 O 2 Lithium-ion battery materials and LiMn 2 O 4...

Embodiment 2

[0059] Weigh 0.2mol lithium nitrate, 0.1mol nickel nitrate, 0.02mol lanthanum nitrate, 0.02mol zirconium hydroxide, 0.06mol manganese nitrate, add them to 1L deionized water, then add 0.60mol citric acid, stir evenly, and then add mass The fraction is 112ml of 50% ethanol solution, stirred at 75°C for 2h to obtain gel;

[0060] The obtained gel was dried at 180 °C for 2 h, and then calcined at high temperature at 620 °C for 2 h to prepare Li(Ni 0.5 La 0.1 Zr 0.1 Mn 0.3 )O 2 Lithium-ion battery material, denoted as LN 0.5 L 0.1 Z 0.1 M 0.3 O 2 .

[0061] Using the same battery assembly method as in Example 1, the battery prepared in this example was tested to have a specific capacity of 176mAh / g for the first discharge at 60°C and 1C. After 100 cyclic voltammetry tests, the retention rate was 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com