Preparation method of black waxy corn beverage

A technology of black waxy corn and black waxy corn flour, which is applied in the field of food processing, can solve the problems of long preparation time, etc., and achieve the effects of attractive color, shortened enzymatic hydrolysis time, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of black glutinous corn beverage, comprising the following steps:

[0032] (1) Powder the black glutinous corn dry granules and pass through a 40 mesh sieve, weigh 10 g of black glutinous corn flour, add 150 mL of purified water and 0.030 g of α-amylase, adjust the pH to 5.75 and place it in a 85°C water bath to liquefy 80min;

[0033] (2) After the liquefaction is finished, place it in a boiling water bath to inactivate the enzyme for 5min;

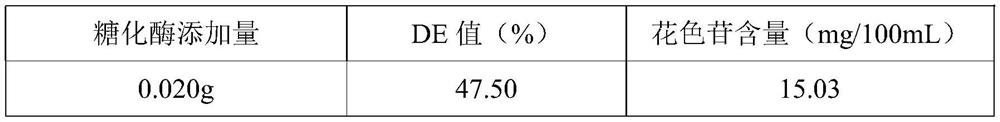

[0034] (3) Add 0.020g, 0.025g, 0.030g of saccharification enzymes to the liquefied liquid respectively, adjust the pH value to 4.25, and place it in a 65°C water bath for saccharification for 120min;

[0035] (4) After the saccharification finishes, place it in a boiling water bath to inactivate the enzyme for 5min;

[0036] (5) centrifuge the saccharification solution for 15min at a rotating speed of 4000r / min, add 0.10% food-grade citric acid and 6% white granulated sugar in the supernatant to prepare the ...

Embodiment 2

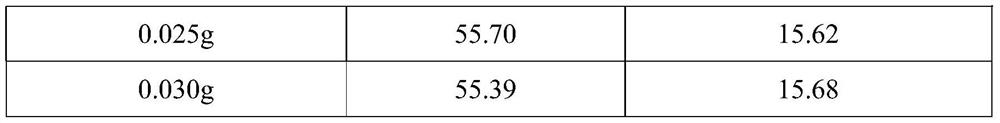

[0043] Adopt the preparation method of embodiment 1, wherein step (3) saccharification condition is to add 0.025g of saccharification enzyme to the liquefied liquid, adjust pH to 4.25 and then place in 60 ℃ water bath for saccharification 90min, 120min, 150min respectively, other steps, Conditions remain unchanged.

[0044] Table 2 Effects of different saccharification time on DE value and anthocyanin content of enzymatic hydrolysate

[0045] saccharification time DE value (%) Anthocyanin content (mg / 100mL) 90min 48.94 17.29 120min 55.74 15.87 150min 56.70 14.70

[0046]The effect of different saccharification time on the DE value and anthocyanin content of the enzymatic hydrolyzate is shown in Table 2. With the extension of the saccharification time, the DE value of the enzymatic hydrolyzate shows an upward trend, which is because the saccharification enzyme is in the hydrolysis of starch or dextrin. When it starts from the α-1,4 glycosi...

Embodiment 3

[0048] The preparation method of Example 1 was adopted, wherein step (3) saccharification conditions were adding 0.025g of saccharification enzyme to the liquefied solution, adjusting the pH to 4.00, 4.25, and 4.50, respectively, and then placing it in a 60°C water bath for saccharification for 120 min, and the other steps, Conditions remain unchanged.

[0049] Table 3 Effects of different saccharification pH values on DE value and anthocyanin content of enzymatic hydrolyzate

[0050] Saccharification pH DE value (%) Anthocyanin content (mg / 100mL) 4.00 52.64 15.59 4.25 53.22 15.69 4.50 50.90 15.36

[0051] The effects of different saccharification pH values on the DE value and anthocyanin content of the enzymatic hydrolysate are shown in Table 3. With the increase of the saccharification pH value, the DE value in the enzymatic hydrolyzate first increased and then decreased. This is because the saccharification pH value increased. Enzyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com